Легкая машина для изготовления сэндвич-панелей из цемента

- Категория: Board Making Machinery >>>

- Поставщик: Guangxi,Hongfa,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 57.32 $* | 58.58 $* |

| Jul-16-2025 | 46.87 $* | 47.30 $* |

| Jun-16-2025 | 56.28 $* | 57.7 $* |

| May-16-2025 | 56.33 $* | 57.70 $* |

| Apr-16-2025 | 45.90 $* | 46.52 $* |

| Mar-16-2025 | 55.10 $* | 56.84 $* |

| Feb-16-2025 | 54.31 $* | 55.98 $* |

| Jan-16-2025 | 54.16 $* | 55.44 $* |

Характеристики

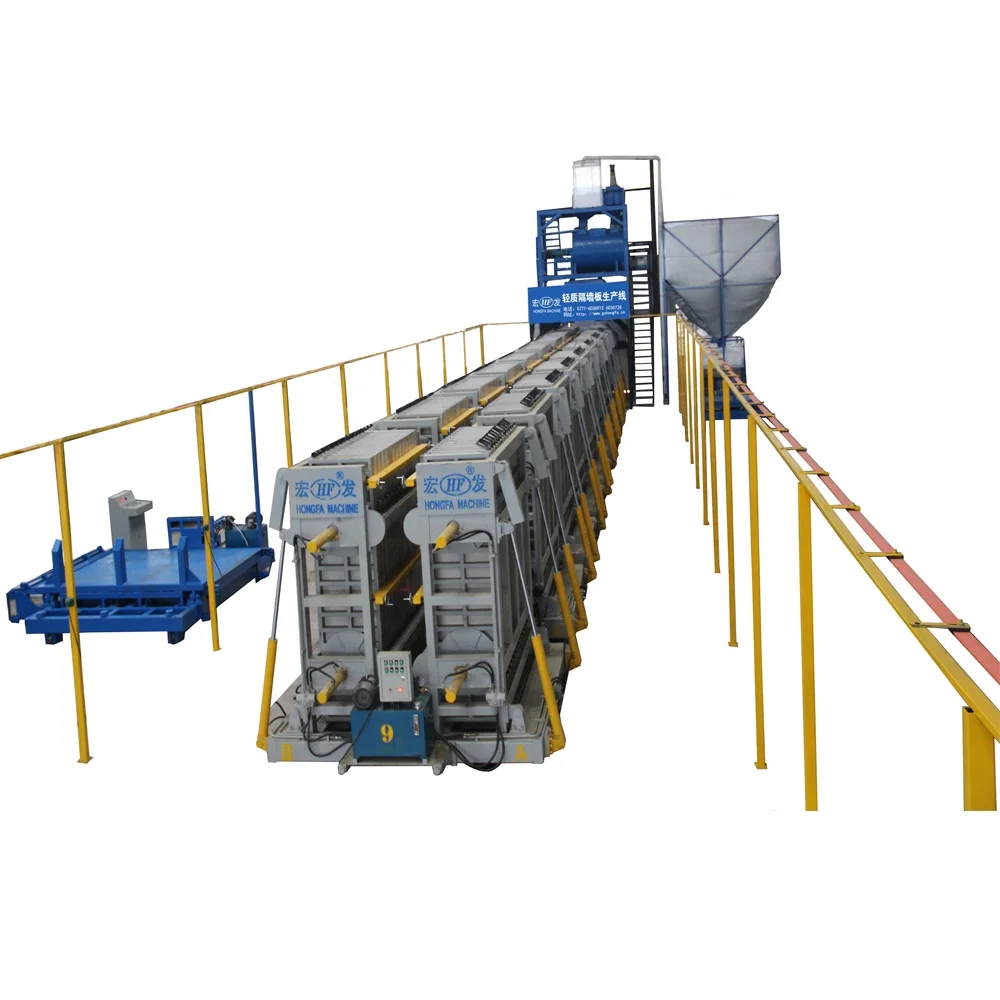

Lightweight fiber cement board sandwich wall panel making machine eps cement sandwich panels machines

Fast construction precast light weight eps concrete panel machine panel making machinery feature:

1.Full Automatic

2.Eco Saving and Advanced Technology

3.Low cost

4.ISO9001-2015

Introduction of Eps cement sandwich panel production line/lightweight concrete wall panel forming machine

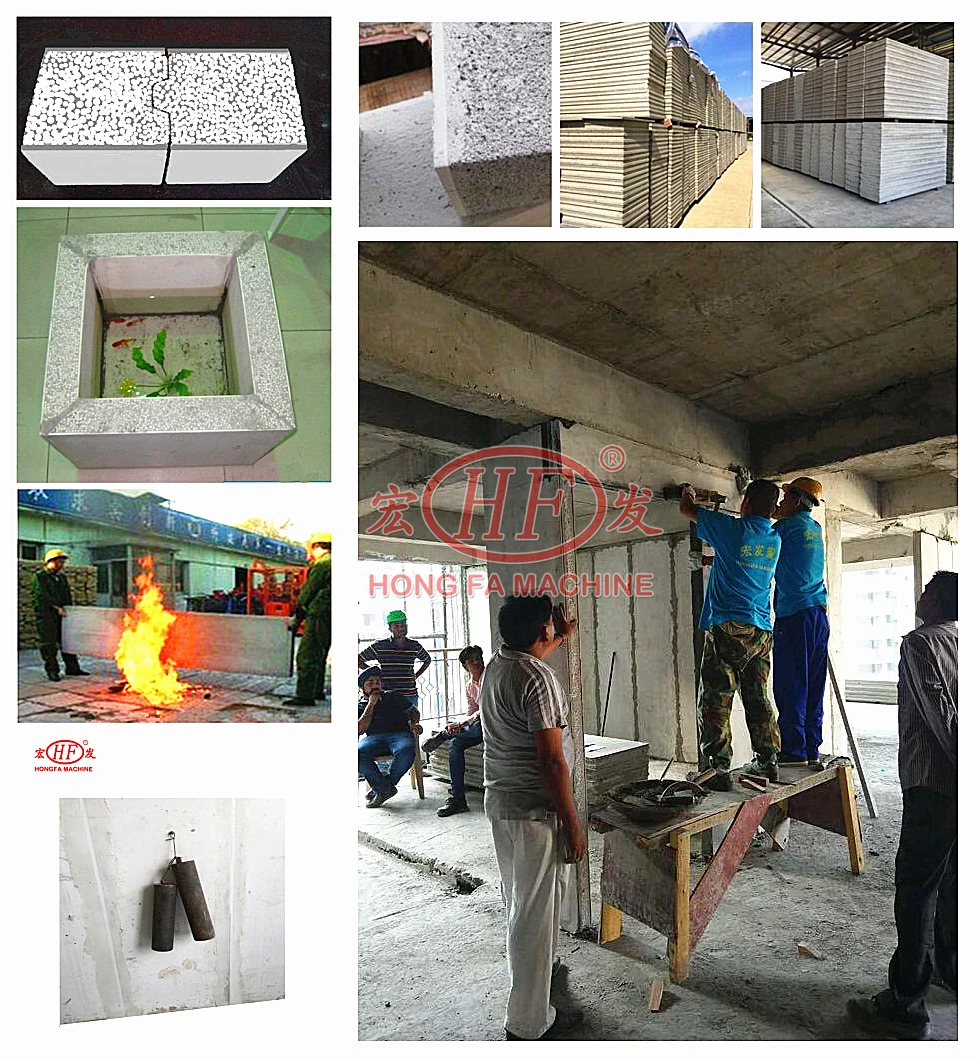

1. Materials of Hongfa Brand EPS Wall Panel

1) Outside (side board)- Calcium silicate board or Cement fiberboard - Also can be without the side board.

2) Inside (core material)- Cement, Foam EPS, Fly Ash, Additives (Hydroxypropyl methyl cellulose) Or without EPS foam The fly ash can be replaceable by sand or other material

(3) Materials of Gypsum board: Gypsum powder, water, additive, ect.

2. Hongfa Manufacturing Machines Eps Sandwich Wall Panel Production Line/Machine

Lightweight wall panel size range:

L*W*T: 2440mm*610mm*50mm/60mm/75mm/90mm/100mm/120mm/150mm.

2270mm* 610mm*50mm/60mm/75mm/90mm/100mm/120mm/150mm/180mm.

Length and wide can be customized.

Fast construction precast light weight eps concrete panel machine panel making machinery

♦ The EPS lightweight wall panel machine specializes in the production of light weight wallboard which has a flat surface, smooth and high density and this production line realizes the industrial zation of the new building partition panel material.

♦ Simple and reliable operation, mature and stable equipment and technology. These advantages greatly eliminate random operation during the construction process.

♦ The unique mixing technology and molding process can lower the water and cement ratio of lightweight concrete aggregate, improve the performance of the wall panel strength, reduces shrinkage value of wall panel.

The Advantages of Lightweight Concrete EPS Wall Panel Machine:

♦ High precise guiding pressure reducing valve controls the temperature and steam pressure of the closed barrel, ensuring the outcome pressure of the valve constant and the inner temperature controlled within ±1%, which keeps the foamed material equal and prevents the bead agglomerate because of the bad temperature control.

♦ With photoelectric or vibration sensor to control material level, ensuring density tolerance within ±3%.

The Sandwich Lightweight EPS Cement Making Machine Features:

♦ Most components of eps light weight wall panel making machine are of world-famous brands, with reliable performance, stable quality, long service life and low maintenance cost.Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

Flexible Finished EPS Sandwich Wall Panel Size and Thickness

♦ The EPS cement insulated sandwich panel making equipment is equipped with fluidized bed dryer, including drying, automatic sieving, depluming and material conveying to silos.

♦ The size and thickness (60~180mm) of lightweight EPS wall panel can be adjustable.

Suggested Staffing Table of Lightweight fiber cement board sandwich wall panel making machine eps cement sandwich panels machines

| Position | Amount(Person) |

| Moulding/pouring | 1 |

| Demoulding&Packing | 1 |

| EPS Expander Operation/raw materials | 1 |

| Mixer Operation | 1 |

| Transportation | 1 |

| Total | 5 |

Hongfa has three types of Eps Sandwich Wall Panel Production Line

1. Automatic Horizontal type Hongfa Manufacturing Machines Eps Sandwich Wall Panel Production Line/Machine:

2. Manual Vertical type Hongfa Manufacturing Machines Eps Sandwich Wall Panel Production Line/Machine:

3. Full Automatic Vertical type Hongfa Manufacturing Machines Eps Sandwich Wall Panel Production Line/Machine:

Q: How can you guarantee the production quality ?

A: Our production quality follow China construction machinery standard JGJ33-2012. We have 30 years experience on producing the machines and will be inspected by QC team for each shipment. We have strictly quality control system in our production process. We have 4 times inspection for each finished product before package Third part inspection acceptable.

Service

Guarantee for one year and after sale service for whole life.To offer free design,free technology support and free machine maintenance trainning.

Why choose Hongfa Machinery Group

Hongfa Group Established in 1990.

A leader developer& Manufacturer of Construction Material Machinery.

Main business Range & Products:

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

Hongfa Strengths

More than 30 years experience. 1500 employee (50+engineers)

2) Total 4 factories with 440,000M2 and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.

Group'Honor

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.National Enterprice Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protectionb Demonstration Unit

4.High and New Tech Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

If you are interested in any product of our company, please feel free to contact me.

Any enquiry would get our professional and prompt reply!