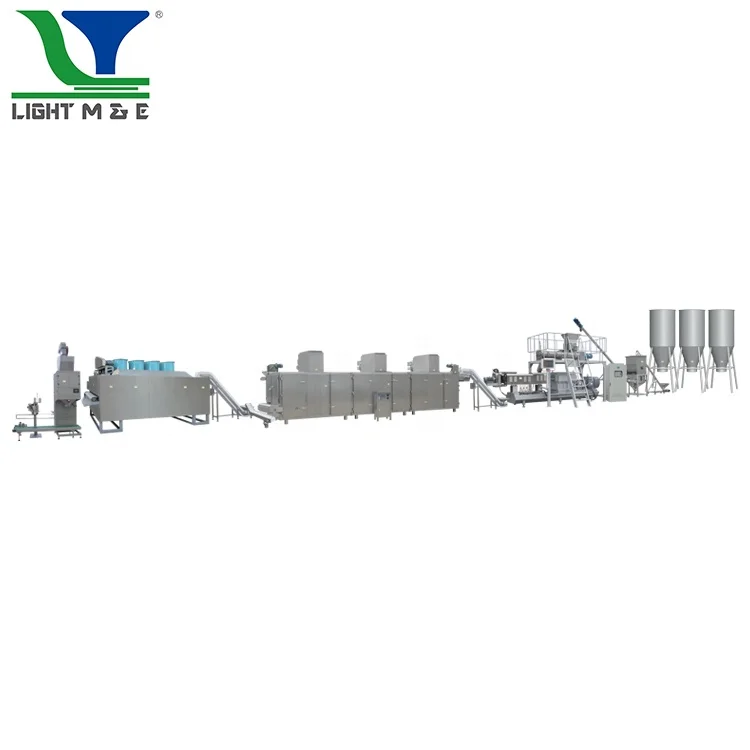

Машина для корма в гранулах собак и рыбок хорошего

- Категория: Оборудование для переработки рыбы >>>

- Поставщик: Shandong,Light,M&e,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 95200.62 $* | 99960.73 $* |

| Aug-15-2025 | 94400.75 $* | 99120.58 $* |

| Jul-15-2025 | 79200.97 $* | 83160.20 $* |

| Jun-15-2025 | 92800.85 $* | 97440.6 $* |

| May-15-2025 | 80800.28 $* | 84840.59 $* |

| Apr-15-2025 | 91200.1 $* | 95760.59 $* |

| Mar-15-2025 | 90400.33 $* | 94920.81 $* |

| Feb-15-2025 | 89600.98 $* | 94080.35 $* |

| Jan-15-2025 | 88800.26 $* | 93240.63 $* |

Характеристики

Product Application

With the increasing variety of pet, people require more and more different pet foods. In order to meet various feeding demands, Our company developed this line, easy operation, friendly human-machine interface, accurate control to ensure the food can be processed under stable temperature, pressure, humidity and other circumstance.

This line mainly use the meat meal, fish meal, bone powder, corn powder, soya meal and other grains' powder as main materials to produce the innovative shapes, high nutritional and savory taste pet food for dog, cat, fox, bird etc.

Why you need to choose Us

1. The screw is made of alloy (38CrMoAL) by nitriding process, high strength and wear-resting. And it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

2. It adopts speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine guarantees stable materials feeding in the whole food process.

3.The gearbox has automatic lubrication function, with extends gear life.

4. Radiator is increased on driving part for forced cooling effect, and it ensures extruder operate safely.

5. Barrel with water-cooled circulation, it makes extruder can be used not only for corn/rice, also for wheat flour/starch which are raw materials with high viscosity. Through different moisture-extrusion temperature ratio, it can make whole-expanded and half expanded as different type of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

Model | Installed Power | Power Consumption | Output | Size |

LT65 Pet Food Process Line | 80kw | 56kw | 120-150kg/h | 22500x1200x2200mm |

LT70 Pet Food Process Line | 128kw | 90kw | 200-250kg/h | 25000x1500x2200mm |

LT85 Pet Food Process Line | 175kw | 123kw | 300-600kg/h | 30000x3500x4300mm |

LT90 Pet Food Process Line | 287kw | 216kw | 1000-1200kg/h | 40000x2400x4000mm |

FT75 Pet Food Process Line | 186kw | 139.5kw | 300-600kg/h | 24000x2000x2800mm |

FT95 Pet Food Process Line | 383kw | 287kw | 1000-1500kg/h | 40000x3000x4000mm |

FT115 Pet Food Process Line | 424kw | 318kw | 2-3T/h | 42000x3000x4000mm |

FT130 Pet Food Process Line | 502kw | 376kw | 4-5T/h | 46000x3000x4000mm |

Mixer

Material: Stainless Steel

Capacity: 40kg/7mins

Function: This equipment can mix material,water and other additives.It's the first step of food processing.

FT-series extruder

Machine part: Siemens ChinaMain Motor, Japam FUJI, Korean LG Electric Parts, Taiwan Delta Inveter

Function: Extruding the mixture into different shapes of snack foods based on different parameters

Drying time: 15 to 60 min; Time can be change according to user's requirement.

Function: This kind of oven has a wide range of application. It can dry all shapes of puffing food, including strip, lump, granular materials etc, as well as other types of materials.

Flavoring roller

Advantage: Rotary roller adopts complete molding without dead angle.

Function: To make food overturning inside the coating drum,

to catch more oil and flavors. The materials, flavoring and oil are stirred and mixed in the roller until well distributed.

Details of cooperation:

(1) Payment terms: 30% of the amount should be paid as deposit, and the balance 70% should be paid before shipment by T/T.

(2) Installation: We will send engineers to the buyer's factory for a 10-day period installation and training to the operators. All the related expenses will be on the buyer's account ( Ticket, food and accommodation ). And the installation fees is USD 80 per day.

(3) After the receipt the advanced payment, we will provide allocation chart at the buyer's request. When effect the shipment, we'll provide operation manual, etc. in English.

(4) Guarantee :We provide some spare parts for free and provide one years guarantee.