2000 мл автоматическая линия выдувного формования/система с емкостью

- Категория: Stretch Blow Moulding Machines >>>

- Поставщик: Zhangjiagang,City,Fillpack,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.6 $* | 0.83 $* |

| Aug-19-2025 | 0.29 $* | 0.34 $* |

| Jul-19-2025 | 0.77 $* | 0.91 $* |

| Jun-19-2025 | 0.1 $* | 0.39 $* |

| May-19-2025 | 0.94 $* | 0.61 $* |

| Apr-19-2025 | 0.11 $* | 0.82 $* |

| Mar-19-2025 | 0.20 $* | 0.96 $* |

| Feb-19-2025 | 0.1 $* | 0.79 $* |

| Jan-19-2025 | 0.52 $* | 0.64 $* |

Характеристики

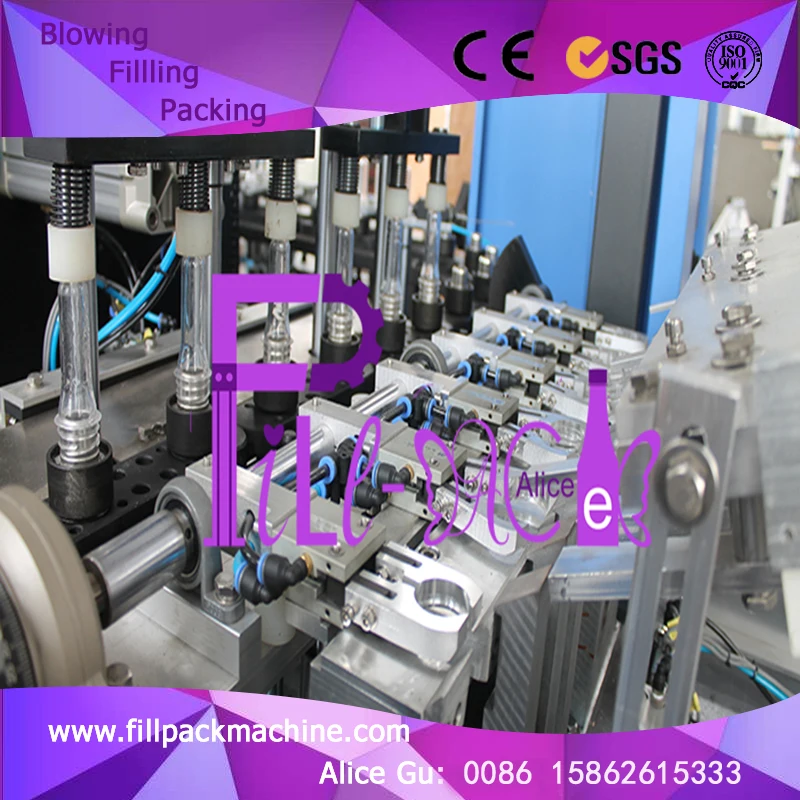

2000ml Automatic blow moulding line/system with 6000BPH capacity

Blow system is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle, oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Multi-line perform loading device

6 cavity blowing photo for ref

6 line heating oven photo for ref

| \t | ||

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | |

| \t | ||

| \t | \t | |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | |

| \t | \t | |

| \t | \t | \t |

| \t | \t | |

| \t | \t | |

| \t | \t | \t |

| \t | \t | |

| \t | \t | |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | |

| \t | \t | \t |

| \t | \t | |

| \t | \t | \t |

Features of main body:

1). Stable performance with advanced PLC.

2). Automatic preform conveyer to save human cost.

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity in variable.

5). High safeties with security automatic-locking device in each mechanica laction, whichwill make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Introduce the FESTO air cylinder to avoid contamination and noise.

7). Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

8). Strong clamping force with high pressure and double crank links to lock the mould.

9). Two ways of operating: automatic and manual.

10). Safe,reliable and unique design of the position of valve to make the pneumatic diagram in the machine easier to understand.

11). Low cost,high efficiency,easy operation and maintenance etc, profited from the fully automatic technological process.

12). Ideal cooling system make the finished bottles without any flaws.

13). Easy for you to install,test and start up.

14). Low rejection rate: less than 0.2 percent.

1+2 semi automatic PET water bottle making machine high quality

PET water bottle making machine

semi automatic plastic juice bottle making machine with varieties shapes

1+1 2 cavity semi automatic beverage bottle blowing machine

1. the blow moulding line is packed by wooden case.

2. The delivery date of blow moulding line is within 30 days after payment.

1.installation&commissioning

After the equipment arrived at the customer's site. the customer is responsible for unpacking and arranging the equipment according to the placement drawing;Our technician will do equipment set up and commissioning,buyer should offer necessary help if needed

2.Training

We are responsible for offering the technical training to user.Through training,users' technical staff can grasp and the skill of operation and maintenance proficiently.The buyer also can send staff to our company for learning.

3.Quality assurance

The warranty period is 12 months after acceptance chech of the production line. if there is any different between the furnished equipment in the customer's factory and the equipment concerned in the contract.

1.Why do you choose our factory?

There are many foreign guests cooperate with our company.We have enough experience and fund to provide you the high-quality products with the best price.

2.How long can you delivery?

About 30 days after we received the deposit(30%T/T in advance,70%T/T before shipment.)

3.How about your after-sale service?

One year repair for free Seller responsible for arrange engineer for installation and guide the workers of buyer how to operate and necessary repair,and give buyer a turnkey project.

4.How long can you finished the installation?

About 10-15 days.If the water and electricity is ready.If you have any questions,please do not hasitate to contact me.