Полностью автоматическая система выдувного формования пластиковых бутылок/линия/завод с контролем PLC

- Категория: Stretch Blow Moulding Machines >>>

- Поставщик: Zhangjiagang,City,Fillpack,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.49 $* | 0.16 $* |

| Aug-18-2025 | 0.25 $* | 0.39 $* |

| Jul-18-2025 | 0.38 $* | 0.36 $* |

| Jun-18-2025 | 0.83 $* | 0.53 $* |

| May-18-2025 | 0.33 $* | 0.26 $* |

| Apr-18-2025 | 0.2 $* | 0.17 $* |

| Mar-18-2025 | 0.26 $* | 0.9 $* |

| Feb-18-2025 | 0.51 $* | 0.10 $* |

| Jan-18-2025 | 0.33 $* | 0.32 $* |

Характеристики

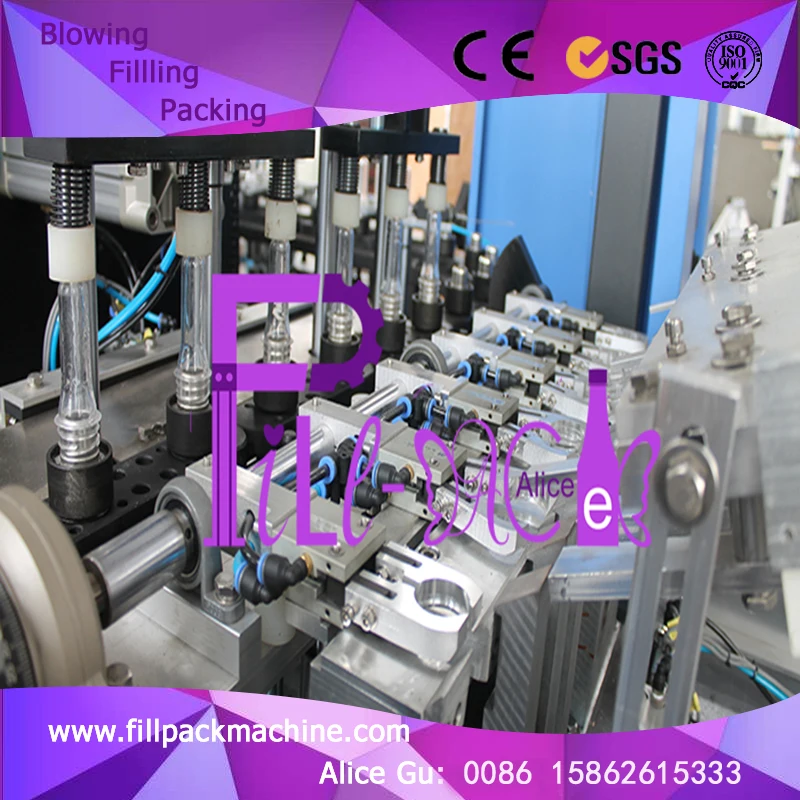

PLC control full automatic plastic bottle blow moulding system/line/plant 6000BPH

FP-6000 type is 6 cavity automatic blow molding machine for neck diameter 28mm. It is full automatic blow molding machine, which is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle, oil bottle, cosmetics wide-mouth bottle and hot fill bottle etc.

Features

2.\tAutomatic preform conveyer to save human cost.

3.\tPreform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4.\tHigh adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

5.\tHigh safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6.\tIntroduce the FESTO air cylinder to avoid contamination and noise.

7.\tSatisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

8.\tStrong clamping force with high pressure and double crank links to lock the mould.

9.\tTwo ways of operating: automatic and manual

10.\tSafe, reliable and unique design of the position of valve to make the pneumatic diagram in the machine easier to understand.

11.\tLow cost, high efficiency, easy operation and maintenance, etc, profited from the fully automatic technological process.

12.\tIdeal cooling system make the finished bottles without any flaws.

13.\tEasy for you to install, test and start up

14.\tLow rejection rate: less than 0.2%.

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | |

| \t | \t | \t | \t | \t | |

| \t | \t | \t | \t | \t | |

| \t | \t | \t | \t | \t | |

| \t | \t | \t | \t | \t | |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | |

| \t | \t | \t | \t | \t | |

| \t | \t | \t | \t | \t | |

| \t | \t | \t | \t | \t | |

| \t | \t | \t | \t | \t | |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | |

| \t | \t | \t | \t | \t | |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

semi automatic UV light heater oil bottle manufacturing machine/equipment/system/plant

oil bottle manufacturing machine

7200 bph carbonated juice bottle manufacturing machine/equipment/line/system/plant

PLC screen automatic control water bottle manufacturing line / system

1. the plastic bottle blow moulding system is packed by wooden case.

2. The delivery date of plastic bottle blow moulding system is within 30 days after payment.

1. Installation & adjustment

After the equipment are arrived at the customer's site, the customer is responsible for unpacking and arranging the equipment according to the placement drawing; and does under our install-adjust technicians' guidance. Costs of the staff are decided at last.

2. Training

1). We are responsible for offering the technical training to user. The training content includes the structure and maintenance of the equipment, control and operation of the equipment. Through training, users'technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time. We will appoint qualified technical staff for the guidance.

2). The buyer can send staff to our company for learning.

3. Quality assurance

1). We guarantee the goods offered are brand-new, not used, with latest design and suitable material made, and we guarantee the specification of the equipment is consonance with the contract.

2). We guarantee the line achieve product technical performance indicators within 5 days after feeding operation through the correct guidance of the installation and commissioning.

3). We are responsible for the fault and damage of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc. that all belong to our responsibility.

4). The warranty period is 12 months after acceptance check of the production line. If there is any different between the furnished equipment in the customer's factory and the equipment concerned in the contract, the users have the right to pass the inspection book to the legal department to claim for compensation to our company within goods warranty period.

4. Warranty

Offer 12 months maintenance period to the problem that caused by our design, manufacture and the material quality, and offer the relevant parts and effective service for free for above reason. We will offer a widely and favorable technical support, after service all the time after guarantee period.

ZhangJiaGang City FILL-PACK Machinery Co.,Ltd. is loacated in Zhangjiagang city which is famous for beverage machinery producer collection. Intergrated the industry advantange and its own development in R&D, production, sales, after sales service, FILL-PACK is ready to serve more and more customers with our full range products and satified service.

FILL-PACK product is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

At present we produce: production lines for mineral water, pure water, fruit juice, tea drink, milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 80-1200 barrels per hour and various water treatment plants; We provide separate machinery or turnkey project.

Our product pass quality inspection executed by Bureau of Quality and Technical Supervision every year. Our factory is in accordance with ISO9001: 2000 certification system standards and we gain CE certificate for exportation to Euro countries. Our machineries are sold to more than 30 cities in China and over cross to American, Spanish, Hungary, middle east and African countries.

We help to set up your factory as our own home with our pure heart, we do to service, we learn to support!