Автоматическая Высокоэффективная бак из нержавеющей стали RO система очистки питьевой

- Категория: Обработка воды >>>

- Поставщик: Shenzhen,J&D,Drinking,Water,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.1 $* | 0.74 $* |

| Aug-17-2025 | 0.14 $* | 0.28 $* |

| Jul-17-2025 | 0.51 $* | 0.77 $* |

| Jun-17-2025 | 0.38 $* | 0.35 $* |

| May-17-2025 | 0.13 $* | 0.28 $* |

| Apr-17-2025 | 0.19 $* | 0.94 $* |

| Mar-17-2025 | 0.41 $* | 0.53 $* |

| Feb-17-2025 | 0.57 $* | 0.44 $* |

| Jan-17-2025 | 0.99 $* | 0.28 $* |

Характеристики

Automatic high efficiency Stainless steel tank RO system Drinking water treatment machine

Functions and Features

- Adopting SS304 materical with opening design, clear process and convenient maintenace.

- High quality TFC compound Romembrane treatment crafts with very low pressure and the capacity of desalinization ration comes to 98% at least.

- Auto-check conductance display guarantee watching water quality.

- Multi medium beforehand filter increases the capacity of water treatment.

- Adopts high efficiency active carbon filter which can wipes chlorine of raw water , protect RO membrane and adjust the taste.

- Safe and reliable electrical system designequipment auto stop protection when open circuit,short circuit and creepage.

- Intelligent circuit design equipment auto stop and run when high or low level water.

- RO membaranes auto wash and manual wash ,which can protect RO membrane easily.

Remarks

We can use fiber-glass membrane housing,stainless steel membrane housing,fiber-glass filter tank ,stainless steel filter tank and pump & RO membrance of different brands.

Specification

| Model | JND RO1000 |

| Capacity of pure water | 200-80000LPH |

| Power Supply | AC380V/415V±5% 50Hz/60Hz |

| RO Stage | One Stage or two stage |

| Desalinization Ratio | ≥97% |

| Rated Operating Pressure | 0.7-1.5Mpa |

| Temperature of Raw Water | 1-45℃ |

| PH of Raw Water | 2/11 |

| Conductivity of Raw Water | ≤1000US/CM |

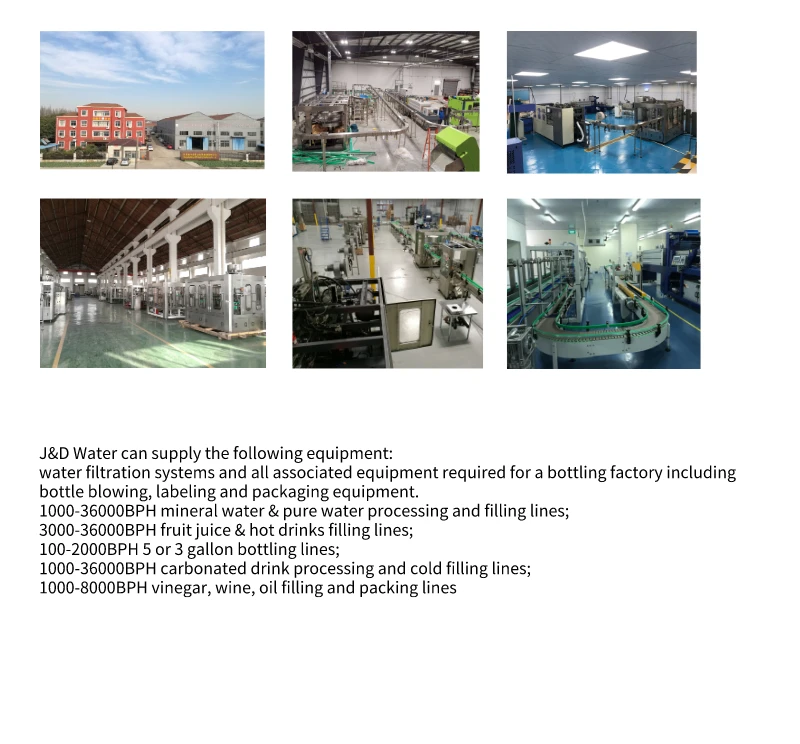

ShenZhen J&D Drinking Water Equipment Co., Ltd. is China's leading manufacturer of bottling equipment and supply the global market with a complete range of bottling equipment and accessories.

J&D Water can supply the following equipment:

* water dispensers, water filtration systems and all associated equipment required for a bottling factory including bottle blowing, labeling and packaging equipment.

*3000-36000BPH mineral water & pure water processing and filling lines

The warranty or guarantee for our drink equipment:

1, the guarantee of our machines is at least two years, also we will send 3% of sales value as spare parts along with the machines free of charge, the parts will be enough for at least 3 years for the normal operation of machines.

2, we can train your engineers in our factory free of charge. It means you can send your engineers to our factory to study and training, we have rich experiences for the training, it is the good way to make sure that you can operate and maintain our machines successfully and for long term normal use.

3, we will offer you detail manual books for our machines, also we will make one Video CD to show you how to install and maintain the machines, the CD is the movie for the machines, it will be the great references for you to maintain the machines for the long time.

4,another way is that we can send our engineers to your factory to install the machines and train your engineers, we think it is the best way to help you operate and maintain the machines. We have been doing the install jobs for our overseas customers for many years. In this way you need to pay for the travel costs for our engineers, because our initial quotes don’t include the travel costs.

5, All of the electrical parts in our machines are CE or TUV approved. We can offer you UL or CUL/CSA approved parts if you need for the North American markets. The good electrical parts are the guarantee for the good quality for our machines.

Which equipment do you need?

Bottled beverage filling machine, 5 gallon bottle water filling machine, 3L-10L bottle filling machine or cup filling machine

Requirements of filling container and capacity.

Bottle, barrel, cup.

Which label do you want to use?

The labeling machines include: hot melt glue labeling machine, cold glue labeling machine, self-adhesive sticker bottle labeling machine and automatic shrink sleeve labeling machine.

What packing method do you want to choose?

The packing machines include: film packing machine and carton packing machine.