Машина для изготовления забора сварочный аппарат проволочной сетки кирпичей Лидер

- Категория: Wire Mesh Making Machines >>>

- Поставщик: Anping,Wanzhong,Wire,Mesh,Products,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.77 $* | 0.14 $* |

| Aug-18-2025 | 0.43 $* | 0.18 $* |

| Jul-18-2025 | 0.42 $* | 0.18 $* |

| Jun-18-2025 | 0.97 $* | 0.31 $* |

| May-18-2025 | 0.92 $* | 0.47 $* |

| Apr-18-2025 | 0.40 $* | 0.49 $* |

| Mar-18-2025 | 0.77 $* | 0.89 $* |

| Feb-18-2025 | 0.95 $* | 0.77 $* |

| Jan-18-2025 | 0.97 $* | 0.18 $* |

Характеристики

fence making machine brick force wire mesh welding machine for hot sale

1 Construction Welded Wire Mesh Machine Most Popular Technical Parameters:

No. | Item | Specification |

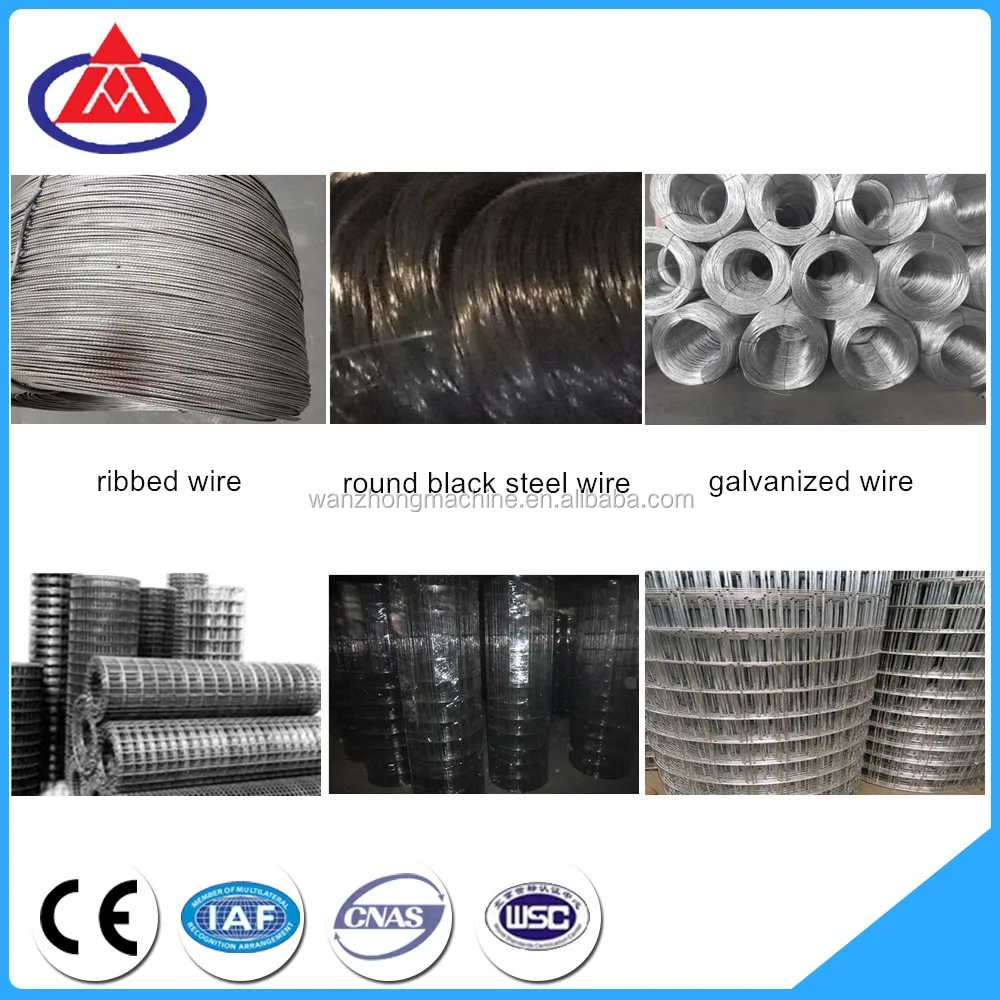

1 | Welding Wire Diameter | Φ2.5-6.0(mm) |

2 | Cross Wire Space | 100-250mm |

3 | Line Wire Space | 100-250mm |

4 | Max Mesh Width | 2500mm |

5 | Max mesh length | panel mesh length:3000mm;roll mesh length:30m |

6 | Number of Electrodes | 24 |

7 | Line Wire Feeding Way | Coil |

8 | Cross Wire Feeding Way | Pre-cut Wire |

9 | Control Way | PLC+Touch Screen |

10 | Welding Speed | 0-80times/min |

11 | Rated Voltage | 380V,50HZ,Three phase or customerized |

12 | Rated Power | 125KWA*3(Water Cooling System) |

13 | Main Motor | 4.0KW (Electromagnetic Brake Motor) |

14 | Welding Time | 10ms-100ms |

15 | Welding Way | By Control Silicon Control Electric Resistance Weld |

16 | Pressure Mode | Adjustable Spring Pressure |

2 Construction Welded Wire Mesh MachineComposition of Whole Production Line:

No. | Name of each part | Quantity/Set |

1 | Main Mesh Welding Machine | 1 |

2 | Line Wire Straightening Device | 1 |

3 | Cross Wire Automatic Falling Hopper | 1 |

4 | Operation Control Cabinet | 1 |

5 | Automatic Cutting Mesh Machine(chosen according to your practical needs) | 1 |

6 | Wire Straighteng and Cutting Machine | 2 |

7 | Level Spare Parts Box | 1 |

8 | Water Cooling System | 1 |

3 Construction Mesh Welding Machine Main Function Features and Advantages:

1. This machine adopts PLC control technique, both separate-phases welding and welding time composed of digital and integrated electric circuit, more intelligent and rational, once pressing, and separate welding.

2. The line wire is fed from coils; the cross wire is pre-cut, fed from hopper driven by step motor.

3. Mesh pulling system adopts servo motor back and forward to ensure the mesh opening accurately and can be adjusted freely within a certain range.

4.At the same time, the machine is also equipped with automatic cutting mesh machine, when the machine finishes the mesh length according to the setting parameters, the mesh will be cut by the cutting mesh machine automatically.

5. The welding speed is fast and it is easy to learn and operate. Only two operators are enough.

6.Finished products are both roll mesh and panel mesh ok.