EPS машина для производства сэндвич-панелей/Сборная бетонная Легкая

- Категория: Board Making Machinery >>>

- Поставщик: Guangxi,Hongfa,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.72 $* | 0.72 $* |

| Aug-17-2025 | 0.49 $* | 0.40 $* |

| Jul-17-2025 | 0.8 $* | 0.38 $* |

| Jun-17-2025 | 0.2 $* | 0.79 $* |

| May-17-2025 | 0.0 $* | 0.11 $* |

| Apr-17-2025 | 0.76 $* | 0.1 $* |

| Mar-17-2025 | 0.75 $* | 0.12 $* |

| Feb-17-2025 | 0.5 $* | 0.37 $* |

| Jan-17-2025 | 0.52 $* | 0.56 $* |

Характеристики

EPS Sandwich Wall Panel Machine / Precast Concrete Lightweight Wall Panel Making Machine Line

Patent protected product

2. Labor-saving and Advanced Technology

3. Double side opening and higher capacity

4. ISO9001-2015

5.Adopts touch screen control, automatic filling, electronic weighing, temperature control,

material level control to realize automatic production.

The Advantage of Automatic Lighteweight Cement Eps Sandwich Wall Panel Machine Production Line Precast Concrete Products Manufacturer

A.fix boards and moulds easily at the same time for both sides, the height is 1.2meters .

(When it is double opening type ).

B. It is convenient to clean the mould and partition board for both side.

C. No panels will fall down when demolding with any thickness of panels, one worker can

demold by automatic demolding & stacking machine safely.

D. Workers can demold finished wall panels while another one can fix the mould and boards for other mold car.

E. Can have natural or hydaulic filling for solid, hollow panels.

F.One workers can control 3 machine, 6 workers can control a Sandwich Wall Panel Machine Production Line with 18 forming machine which capacity is around 500,000 sqm per year .

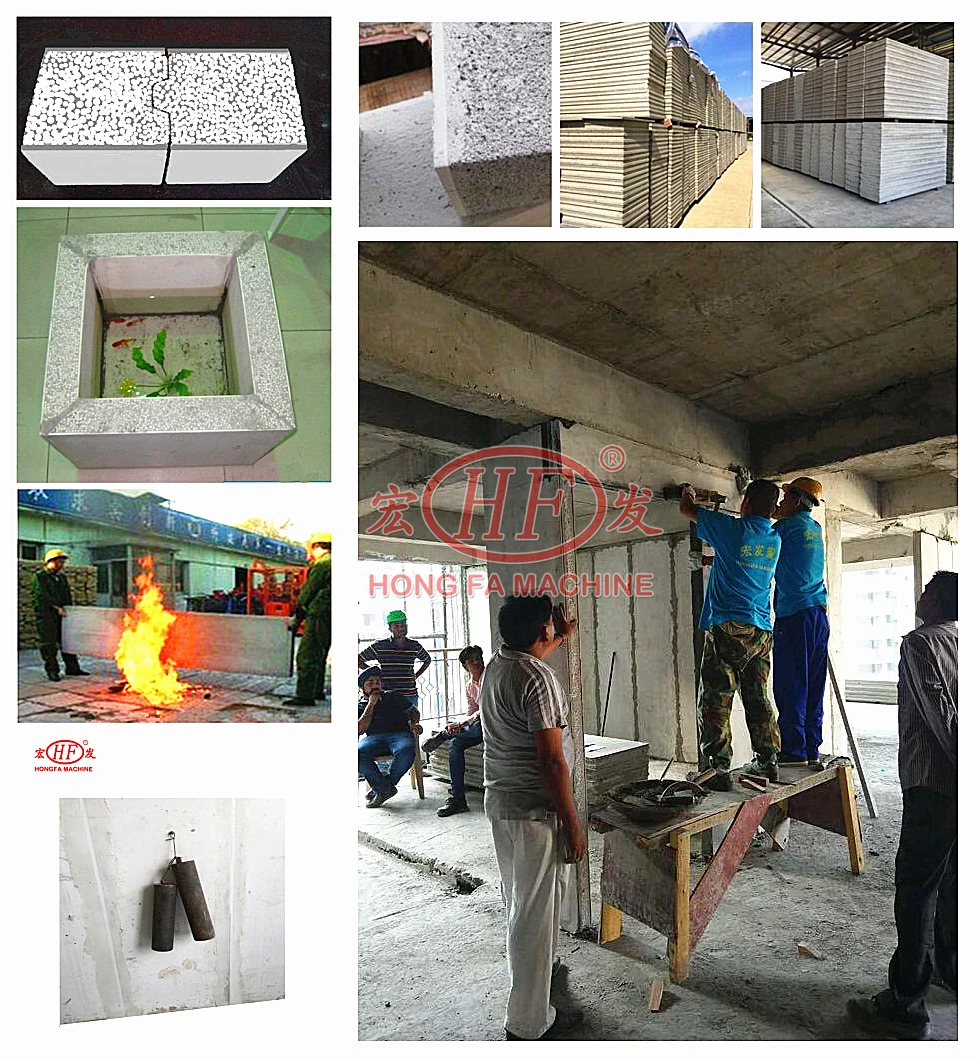

Lightweight wall eps cement sandwich panel production line can produce : Kinds of wall panels

1. Materials of Hongfa Brand EPS Wall Panel

1) Outside (side board)- Calcium silicate board or Cement fiberboard - Also can be without the side board.

2) Inside (core material)- Cement, Foam EPS, Fly Ash, Additives (Hydroxypropyl methyl cellulose) Or without EPS foam The fly ash can be replaceable by sand or other material

2. Hongfa Manufacturing Machines Eps Sandwich Wall Panel Production Line/Machine

Lightweight wall panel size range:

L*W*T: 2440mm*610mm*50mm/60mm/75mm/90mm/100mm/120mm/150mm.

2270mm* 610mm*50mm/60mm/75mm/90mm/100mm/120mm/150mm/180mm.

Length and wide can be customized.

3. Applied range of Eps Sandwich Wall Panel Production Line

For interior and exterior wall partition on steel or concrete structure building, new construction or renovations. It can be widely applied to wall materials of various high and low buildings such as bank, office building, hospital, school, hotel, shopping mall, amusement, old house reconstruction, residence and workshop.

4. EPS new green sandwich wall panel has five features:

(A) Lightweight: It has the characteristics of lightweight, which is only 1/16 weight of the brick and concrete structure.It can significantly reduce the vertical load of the building structure and reduces building weight and project cost.

(B)Insulation Resistance: As this new wall panel is core of EPS insulation materials, which insulation performance is extremely advantageous and meet the building energy efficiency design standards, and rank first among similar products.

(C) Permeability Resistance: The bibulous rate of this new wall panel is only 3.3%,which has reached the international advanced level in the same industry.

(D) Fireproof performance: this kind of wall panel is non-burning, and according to the testing, it is reasonable fireproof materials, for the 90mm thickness wall panel, the fireproof performance can be more 3 hours.

(E) Soundproofing: As new wall panel is using EPS as core, it has good sound insulation and air aspiration, which is more than 40 db sound insulation.

Hongfa Produce Main 3 types of Eps Sandwich Wall Panel Production Line

1. Automatic Horizontal type Hongfa Manufacturing Machines Eps Sandwich Wall Panel Production Line/Machine:

2. Manual Vertical type Hongfa Manufacturing Machines Eps Sandwich Wall Panel Production Line/Machine:

3. Full Automatic Vertical type Hongfa Manufacturing Machines Eps Sandwich Wall Panel Production Line/Machine:

Other related equipment concrete wall panel making machine / production line:

Hongfa Group Established in 1990.

A leader developer& Manufacturer of Construction Material Machinery.

Main business Range & Products:

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

Hongfa Strengths

More than 30 years experience. 1500 employee (50+engineers)

2) Total 4 factories with 440,000M2 and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.

Group'Honor

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.National Enterprice Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protectionb Demonstration Unit

4.High and New Tech Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

Foreign Trade Dept. : Emily Lee

Guangxi Hongfa Heavy Machinery Co., Ltd.

What's app/wechat :+86 15177094840

Wesite: www.gxhongfa.cn

Factory add.: Yilingyan Industrial Zone, Nanning city, Guangxi province, China

You can fine me in facebook, LinkedIn.