Продажа с завода сухой керамической напольной плитки клейкий раствор завод и

- Категория: Dry Mortar Machines >>>

- Поставщик: Zhengzhou,Sincola,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.13 $* | 0.35 $* |

| Aug-20-2025 | 0.61 $* | 0.48 $* |

| Jul-20-2025 | 0.75 $* | 0.54 $* |

| Jun-20-2025 | 0.19 $* | 0.43 $* |

| May-20-2025 | 0.79 $* | 0.42 $* |

| Apr-20-2025 | 0.14 $* | 0.28 $* |

| Mar-20-2025 | 0.95 $* | 0.58 $* |

| Feb-20-2025 | 0.89 $* | 0.70 $* |

| Jan-20-2025 | 0.92 $* | 0.49 $* |

Характеристики

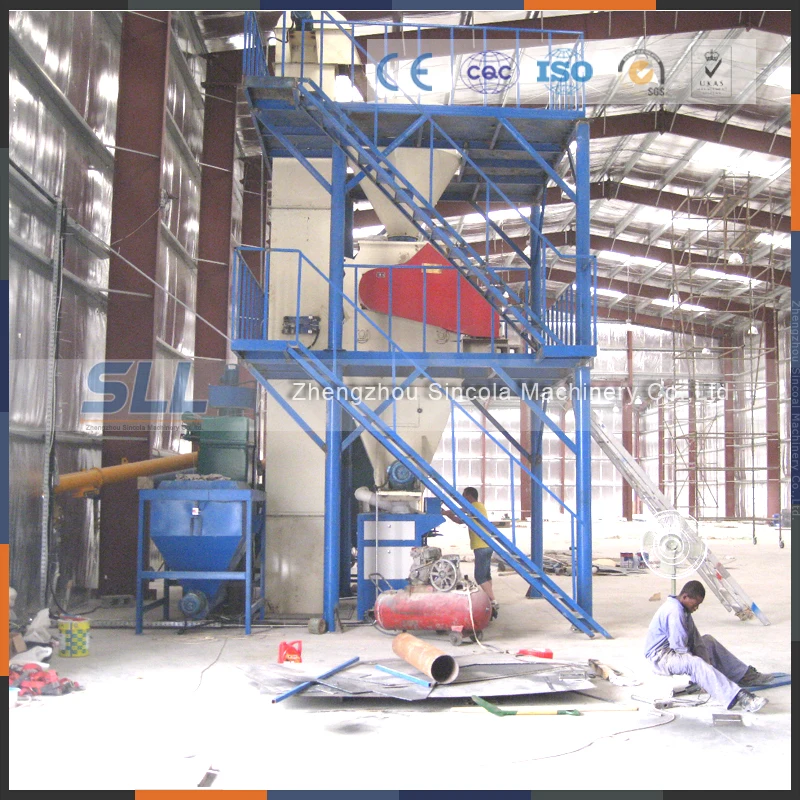

Factory Selling Dry-mix Ceramic Floor Tile Adhesive Mortar Mix Plant and Production

Zhengzhou Sincola machinery the integrated solution supplier of dry mortar production line, provide our cients with high quality machine, formula and special additives for mortar, technical support, and upgrade equipment in lifetime, escort for your success!

Descriptions of Sincola tile ceramic product line for mortar:

dry mortar production line mainly produces ordinary premixed dry mortar and special dry mortar. The whole mortar production line includes Mixing machine, Drying system, Screening system, Measuring system, Bulk and Packing system, Dedusting system, Electrical system and Spot agitation tank.

Sincola Sincola dry mortar Machine plant for drilling for mixing mortar is composed of hoister,pre-blending silo,small silo,mixer,finished products bin,packer,dust catcher,electrical cabinet,gas phase balance system . It adopts double axles blade efficient mixer to avoid breaking raw material and ensure the motar stillstand factor constant . tile adhesive is also called pre-mixed mortar, which made in the factory by precise batching and uniform mixing. It can be used directly just by adding water in construction site. It has different properties though adding different additives. The demand for tile adhesive has increased rapidly due to its outstanding merit compare to the mortar made in job-site.

dry mortar production line Features:

1. Special design for Construction Project;

2. Easy operate;

3. Convenient structures for disassembly;

4. Super property and low production cost;

5. Less space demand;

6.Full -automatic electric operation with PLC/PC control;

7.Electrical weighing system;

8.Twin shaft forced mixing system.

dry mortar production line Parameters:

Mode | Capacity | Area | Height | Note |

Simple | 1-5t/h | 40m2 | 3m | Manual batching and packing |

Basic | 5-15t/h | 40-60m2 | 6-10m | Manual batching ,automatic packing |

Semi Automatic Serial | 5-15t/h | 40-80m2 | 8-12m | Automatic batching of coarse material,manual batching of additive ,automatic packing |

Full Automatic | 5-50t/h | 40-100m2 | 10-25m | Automatic batching of coarse material,manual batching of additive,automatic packing |

Full Automatic Tower | 55~100t/h | 60~500m2 | 10-30m | Automatic batching of coarse material,manual batching of additive,automatic packing |

Type of tile adhesive mortar :

1. Bonding mortar: masonry mortar, wall and floor tile adhesive mortar, pointing mortar, anchorage mortar etc.

2. Decoration mortar: plaster mortar, inner and outer wall putty, colorful decoration mortar etc.

3. Protection mortar: water-proof mortar, anti-corrosion mortar, self-leveling mortar, wear resistance mortar, insulation mortar, sound absorption mortar, repair mortar, mildewproof mortar, shielding mortar etc.

Energy-saving full-automatic dry Mortar Production Line/dry mix mortar plant:

dry mortar production line is a mixture of cement or lime with sand and water. Because this substance is so hard-wearing, it is much in demand in the construction industry. Its primary use is as a bonding agent to hold bricks together solidly. We supply the complete dry mix mortar plant machines, the raw materials Crushing System, Screening System, Washing System ,Drying System Collection System, Powder Material Storage System, Dosing System, Mixing System, Packaging System,Dust Collection System,Electrical Control System etc. By the production line layout can be divided into: Simple type,Basic type,Automatic type, Tower type, Users can choose according to their needs.

Bonding mortar: Masonry mortar, wall and floor tile adhesive mortar, anchorage mortar etc.

Decoration mortar: Decorative plaster, inner and outer wall putty, colorful decoration mortar etc.

Protection mortar: Water-proof mortar, anti-corrosion mortar, self-leveling mortar, wear resistance mortar, thermal insulation mortar, sound insulation mortar, repair mortar, mildewproof mortar, shielding mortar etc.

Keyword: dry mortar production line, dry mortar plant,dry mortar mixing plant,dry mortar mix plant,dry mix mortar plant

A1. We can accept

1. 30%T/T, 70%T/T after inspecting cargo in the factory before delivery.

2. 30%T/T, 70%T/T against B/L copy after delivery.

3. 30%T/T, 70% L/C.

Q2. How to see machine operating before buy it?

A2. We can supply

1. We can supply you our video link for the machine you want, you can watch machine operating on YuTube.

2. We alos welcome customers come to our factory to see machine in person. Maybe you can be our agent in your country.