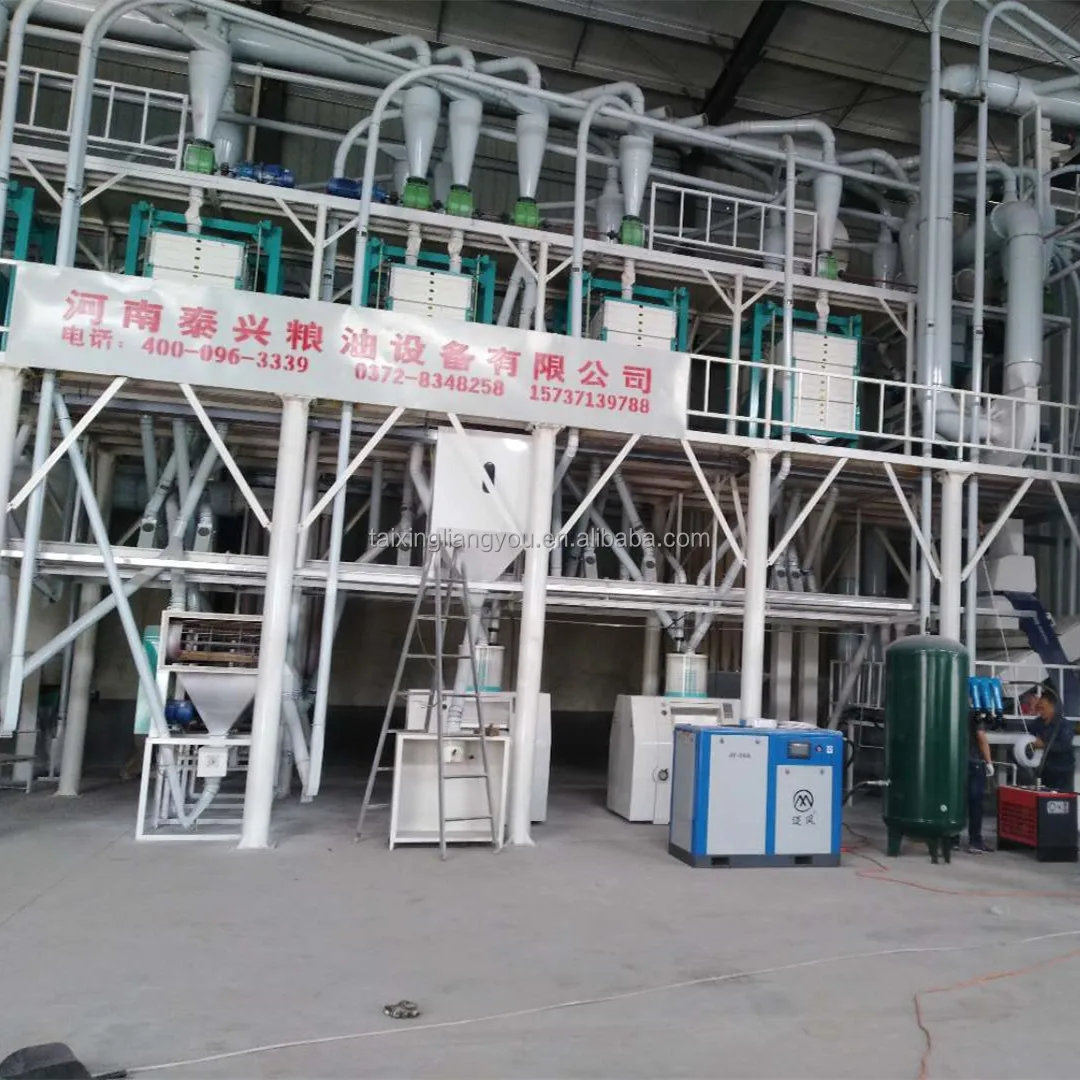

100TPD машина для изготовления кукурузной

- Категория: Grain Processing Machinery >>>

- Поставщик: Henan,Taixing,Grain,And,Oil,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.55 $* | 0.84 $* |

| Aug-18-2025 | 0.7 $* | 0.99 $* |

| Jul-18-2025 | 0.7 $* | 0.1 $* |

| Jun-18-2025 | 0.49 $* | 0.51 $* |

| May-18-2025 | 0.85 $* | 0.49 $* |

| Apr-18-2025 | 0.51 $* | 0.10 $* |

| Mar-18-2025 | 0.8 $* | 0.6 $* |

| Feb-18-2025 | 0.89 $* | 0.28 $* |

| Jan-18-2025 | 0.26 $* | 0.71 $* |

Характеристики

1)This 100TPD machine for making corn flour corn flour milling machine adopts advanced fine corn processing flow-line design with new dry milling method, ensuring quality product up to national standard.

2)100TPD machine for making corn flour corn flour milling machine uses a new advanced control, easy to operate

and high intelli-gence roller mill in which absorbs the advantages of international roller mills.

3) Whole base of cast iron, high intensity,strong steel, well shock absorption and not fixed.

4)Steel frame,simple on structure,complete function, cut by laser cutting machine,high precision and flour at outline.

| \t | |||

| \t | \t | \t | |

| \t | \t | ||

| \t | \t | ||

| \t | \t | \t | \t |

| \t | \t | ||

| \t | \t | ||

| \t | \t | \t | |

| \t | \t | ||

| \t | \t | ||

Main Features of the 100TPD machine for making corn flour corn flour milling machine:

1) high efficiency and low consumption

2) high-quality and competetive price

3) professional technique and unique design

4) scientific configuration and beautiful appearance

5)smoothly running and easy to operate

6) low noise and modern processing workshops

7) installing and training in local place

The process of the 100TPD machine for making corn flour corn flour milling machine:

1)Cleaning Part

Cleaning Parts: this part main used for cleaning the impurities such as the little stoners and light -dust during the raw material such as the wheat and the maize.And this part divides into 2 main steps, Outdoor cleaning and indoor cleaing.

Outdoor Cleaing main separate the big impurities such as the straws and the large stones.

Indoor Cleaning main cleans the little and light impurities our of the grain , such as the dust .

2) Milling Part:

This part is the most important part of flour processing. it will grind the grian such as the wheat and maize to fine flour.Customers can arrange the grinding times as the flour mesh and color.

3)Packing Part:

This part is the ending of flour processing. Custoner can use full-automatic packing machine or semi-automatic packing machine.

Main Features

Name: 100TPD machine for making corn flour corn flour milling machine

Brand: Taixing

Original: China Mainland

Domestic famous engines, unique design , professional installation and best after-service.

Machine Parts

Name: Pipes

Brand: Taixing

Original: China, mainland

Use professional and advanced pipes for the flour's delivery.

Main Features

Name: Screen sieve

Brand:Taixing

Original: China,mainland

This screen sieve can make the corn flour more purify and high-efficient.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

Packing Details :

1.The machine will be packed with the protect film inner and water-proof outside.

2.If the machine less than a container, wooden case packing is necessary.

3.The machine is fixed by steel roper in the container.

4,others to make sure the machine is in good condition when arrived the destination.

Delivery Details:

1, Arrange the machine within 30 days after your order be confirmed and received your deposit..

2, Arrange the shipment within 10 days after we received your full payments.

5ton wheat flour mill.

10ton flour milling machine.

50ton maize milling machine.

Q1: Are you a trading company or a manufacturer?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q2: How can I get to your company?

A: You can get a flight to Zhengzhou Xinzheng International Airport,or you can go here by train to Zhengzhou Railway Station/Zhengzhou East Railway Station

Q3.What’s the Payment?

A:T/T would be better with quick transfer and few bank fees. L/C could also be accept, but the procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q4: Will you send engineers to install the plant?

A:we send engineers to your place for guiding installation. Engineers are responsible for guide installation, test running and training.

Q4: Can you show how the machine works?

A: Certainly, we will send you the Operating video & instruction to you together with machines, to help you use the machines better.