2021 Полностью Автоматическая Этикетировочная машина с термоусадочными рукавами для разных

- Категория: Машины для этикеток >>>

- Поставщик: Zhangjiagang,Paima,Packaging,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 10115.64 $* | 10621.82 $* |

| Aug-16-2025 | 10030.86 $* | 10532.79 $* |

| Jul-16-2025 | 8415.93 $* | 8836.35 $* |

| Jun-16-2025 | 9860.36 $* | 10353.56 $* |

| May-16-2025 | 8585.44 $* | 9014.17 $* |

| Apr-16-2025 | 9690.71 $* | 10175.15 $* |

| Mar-16-2025 | 9605.84 $* | 10085.99 $* |

| Feb-16-2025 | 9520.71 $* | 9996.68 $* |

| Jan-16-2025 | 9435.23 $* | 9907.55 $* |

Характеристики

Product Description

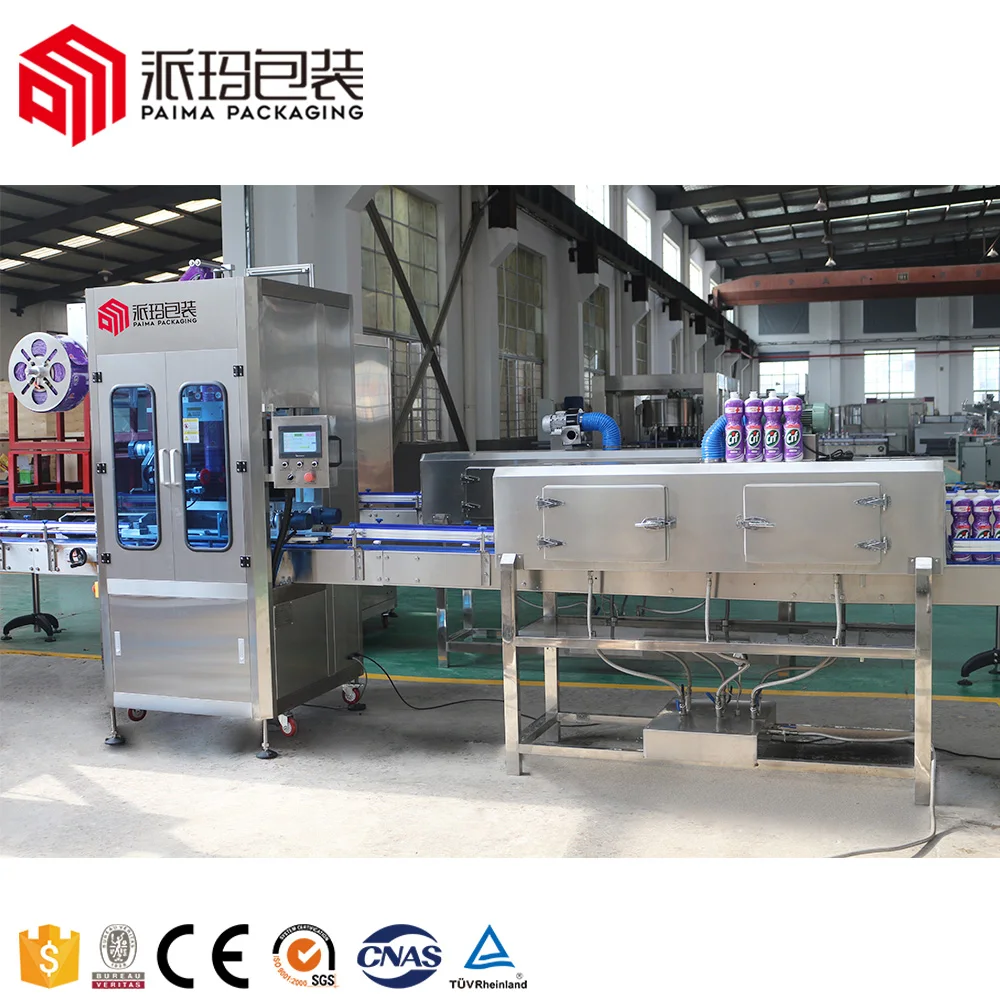

Full automatic sleeve labeling machine

Paima Packaging offers a full range of shrink sleeve label applicators for low, medium, and high-speed production environments. All of our shrink material applicators are capable of performing up to five key sleeving applications:

Full body sleeves, Full body over-the-cap sleeves, Partial body sleeves, Tamper evident bands, Multi-packs etc.

Paima Packaging also offers wide label format models capable of handling label widths up to 900mm. our shrink sleeve label applicators and machine systems are used in a wide variety of industries including fluid milk, craft beer, ready-to-drink beverages, cosmetics, home care products, and personal care products. Their flexibility and reliable performance make them one of the best values in the shrink sleeving industry.

Working pricinple of sleeve labeling machine

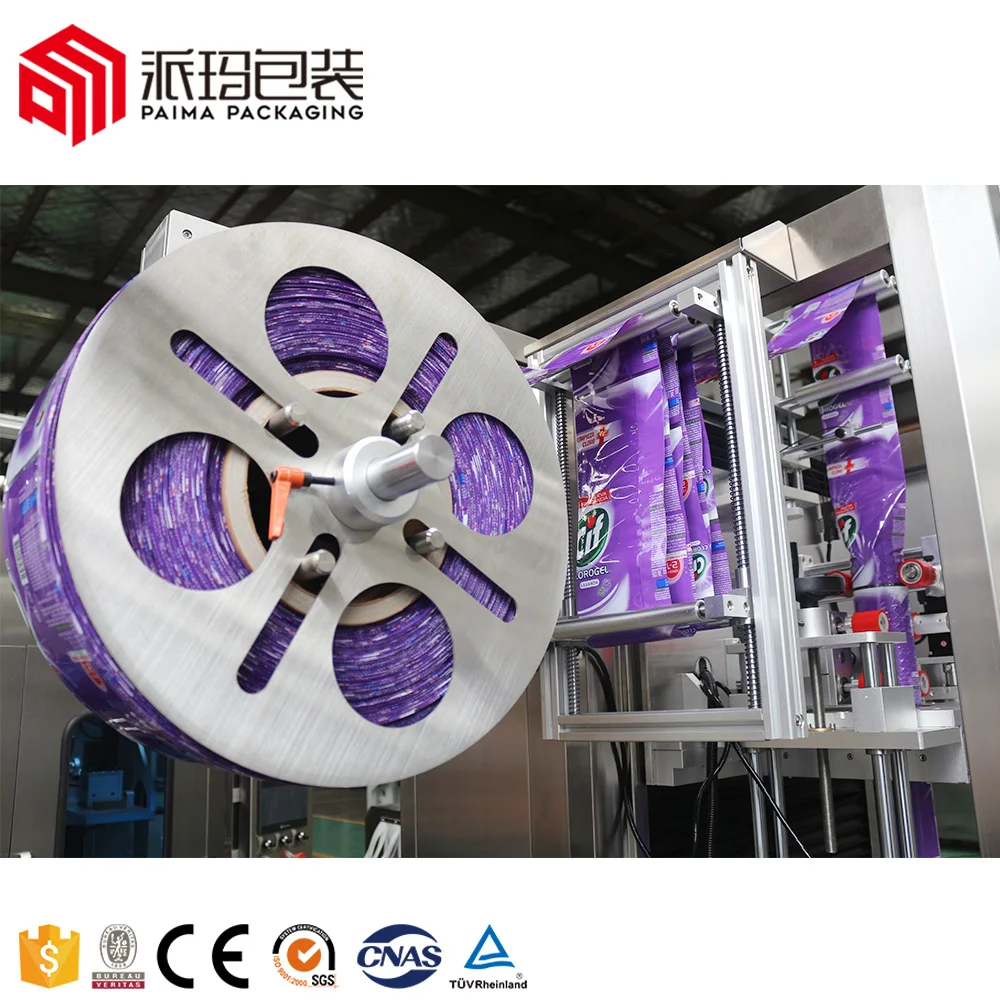

A sleeving machine shoots heat shrinkable plastic sleeves over bottles as they pass by on a conveyor. The sleeves are supplied as lay flats on reels, printed with label information. The fascinating part of a sleeving machine is how it opens the lay flat into a cylinder and then cuts the labels to the correct length at high speed.

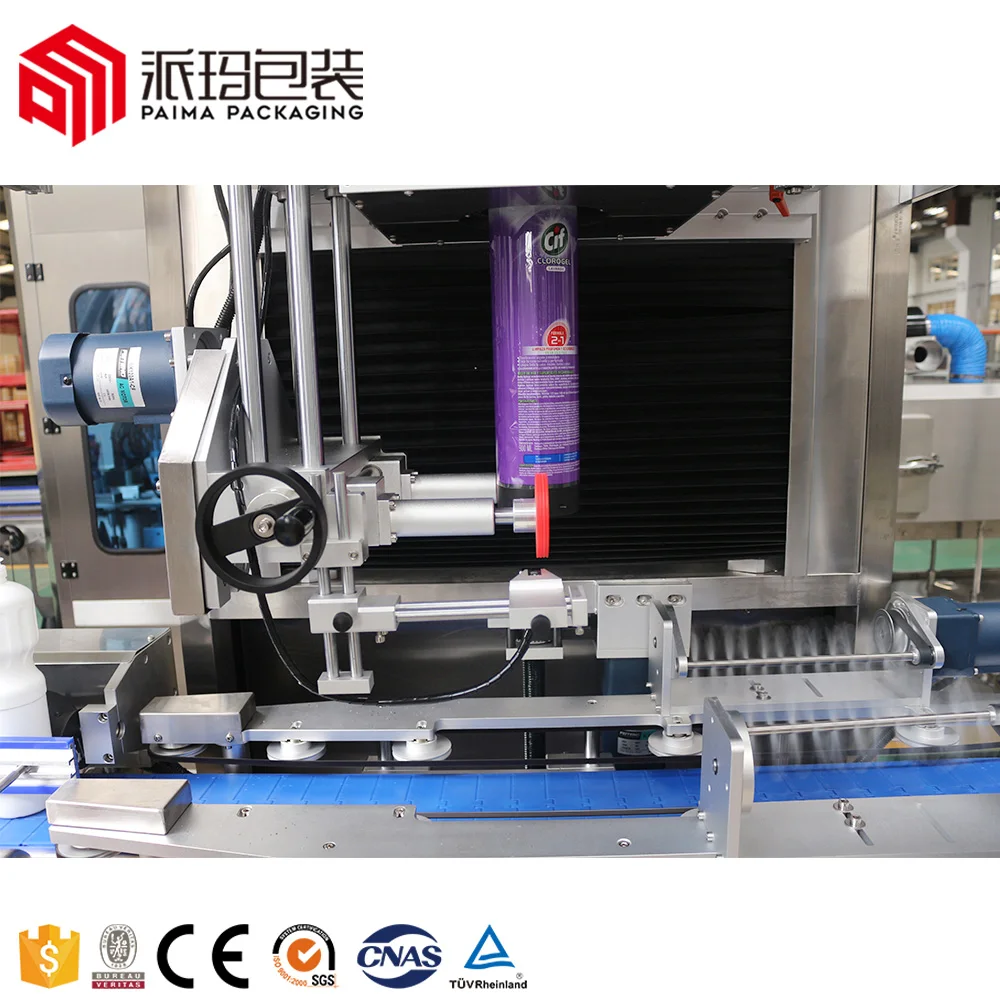

Shrink labeling is a two-step process. First, a heat-shrinkable plastic sleeve is dropped over a bottle as it moves by on a conveyor. Second, the sleeved bottle is conveyed through a heat tunnel that shrinks the label to a snug wrinkle-free fit. A shrink tunnel must subject the bottle to the correct amount of heat for the right length of time. Shrink labeling systems can achieve speeds in the range of 300 bottles per minute depending on the sleeving machine model purchased.

Applications

Food & Beverage Industry

Suitable : Mineral Water, Pure Water

Bottle Material : PET / PE / Glass / Metal

Bottle Type : Round / Square / Unique

Label Material : PVC/PET Shrink Label

Bottle Material : PET / PE / Glass / Metal

Bottle Type : Round / Square / Unique

Label Material : PVC/PET Shrink Label

Daily chemical & Beauty Industry

Suitable : Daily chemical products

Bottle Material : PET / PE / Glass / Metal

Bottle Type : Round / Square / Unique

Label Material : PVC/PET Shrink Label

Bottle Material : PET / PE / Glass / Metal

Bottle Type : Round / Square / Unique

Label Material : PVC/PET Shrink Label

Pharmaceutical & Health Industry

Suitable : Medicine, Health products

Bottle Material : PET / PE / Glass / Metal

Bottle Type : Round / Square / Unique

Label Material : PVC/PET Shrink Label

Bottle Material : PET / PE / Glass / Metal

Bottle Type : Round / Square / Unique

Label Material : PVC/PET Shrink Label

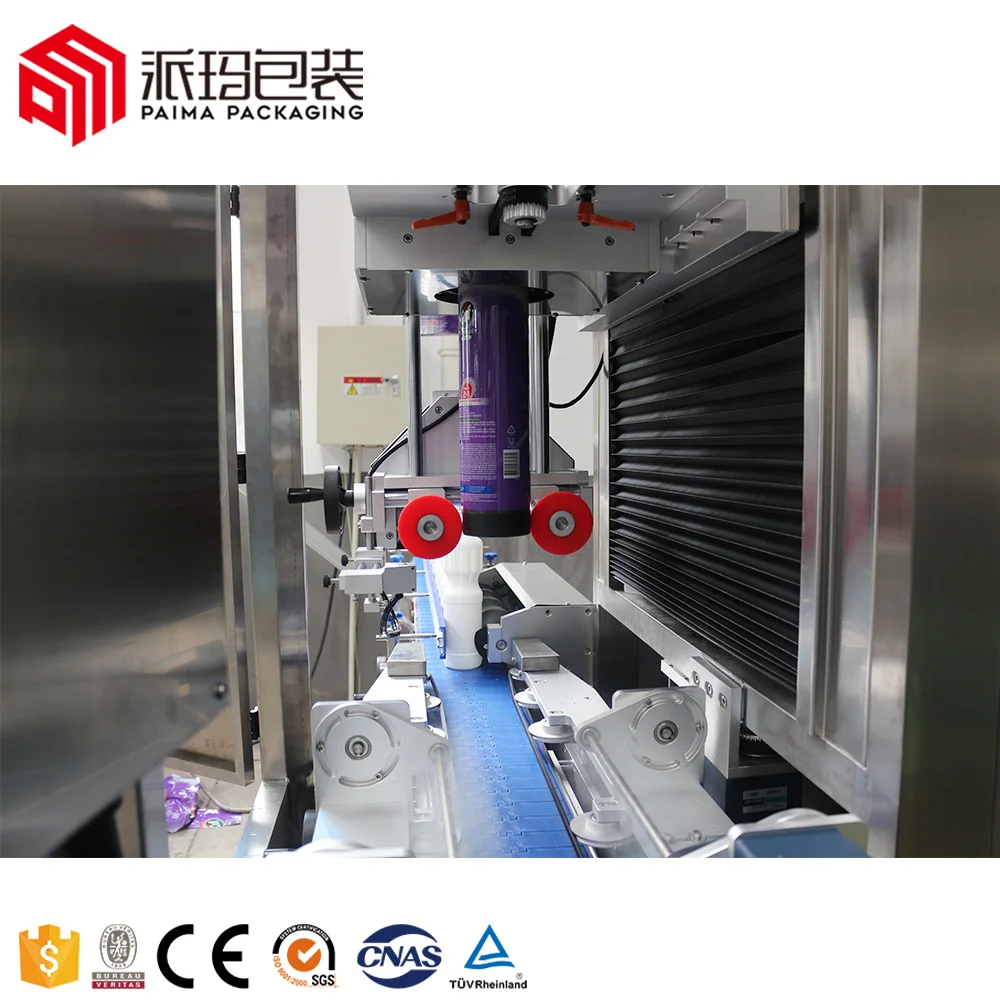

Details Images

(1) PM-series Sleeve Labeling Machine is custom built to meet the exacting demands of manufacturers and suppliers. It can be used stand alone or integrated in-line and matching filling equipment speeds.

(2) It is built upon a framework of seam welded, food grade stainless steel section. This solid foundation keeps movement and vibration to an absolute minimum to ensure consistent, accurate labeling.

(3) Unit cutter head plane design in China which apply to the container of ∮30 mm—∮130 mm. you never need to change or debug it.It also has unique light touch human-machine screen,that means,auto search original location as well as safety and convenience which is ahead of other congener products.

(4) Double shrinking label feed plane, reasonable height which is convenience to fix the label; micro-computer auto figure which avoid enactment and adjustment. you only need to press it lightly ,the label will detect and locate automatically.The change of label is quick and convenience, besides,the cut place is absolutely exact.

Separating Screw

Put the label on the bottle, and use the fixed-distance conveying of the screw to separate the bottles at equal distances to facilitate the labeling.

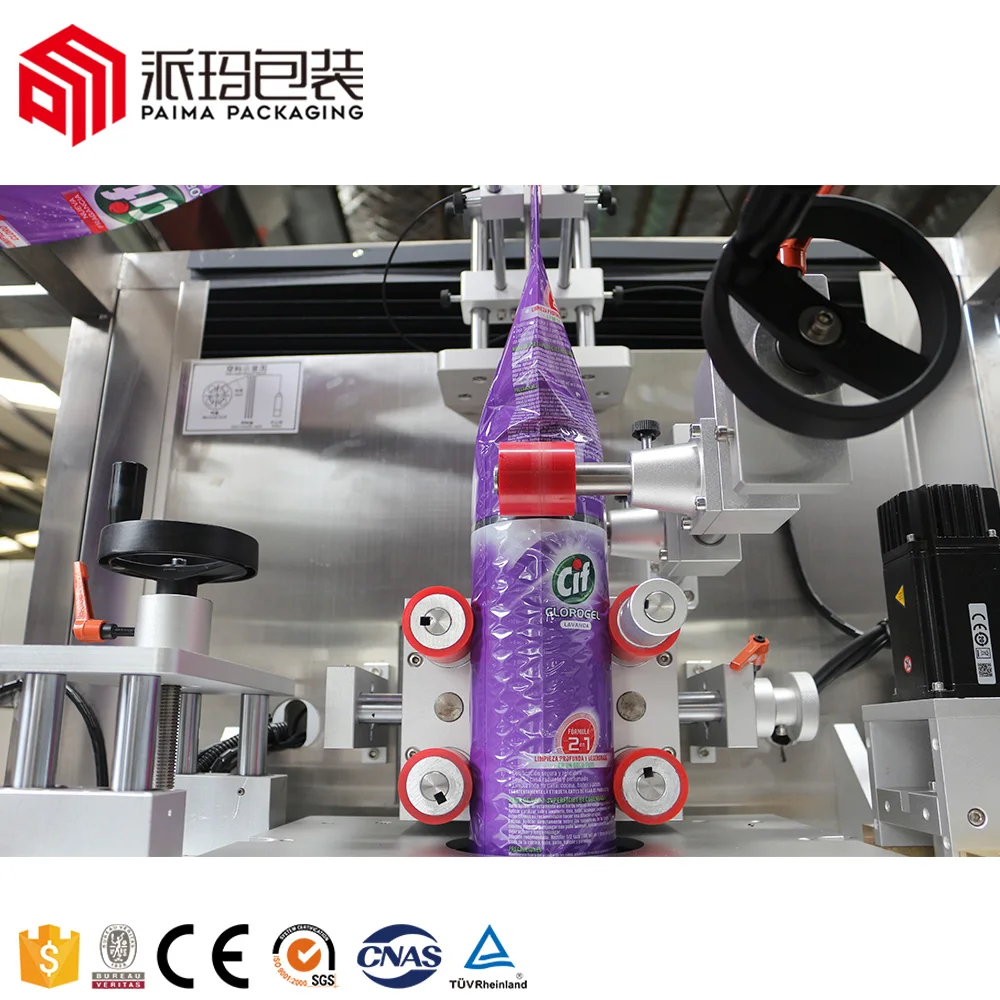

Drive rollers

It adopts single-group or double-group mechanism synchronous servo motor control, so that the shrink film can be conveyed in a fixed size.

Rubber underbrushes

Use rubber to brush the label sleeved in the bottle until it is positioned to avoid incorrect label position.

PLC Control System

It is the control center of this machine. Each operation display page is divided into manual, automatic, setting, abnormal display, etc. In addition, there are several auxiliary knobs, which are used to operate the labeling operation.

Center column

Put the label film material in and open, so that the film material can be conveyed and cut. The whole machine is made of aluminum alloy with anode treatment and 304 stainless steel material, used to support the host and fix the conveyor belt.

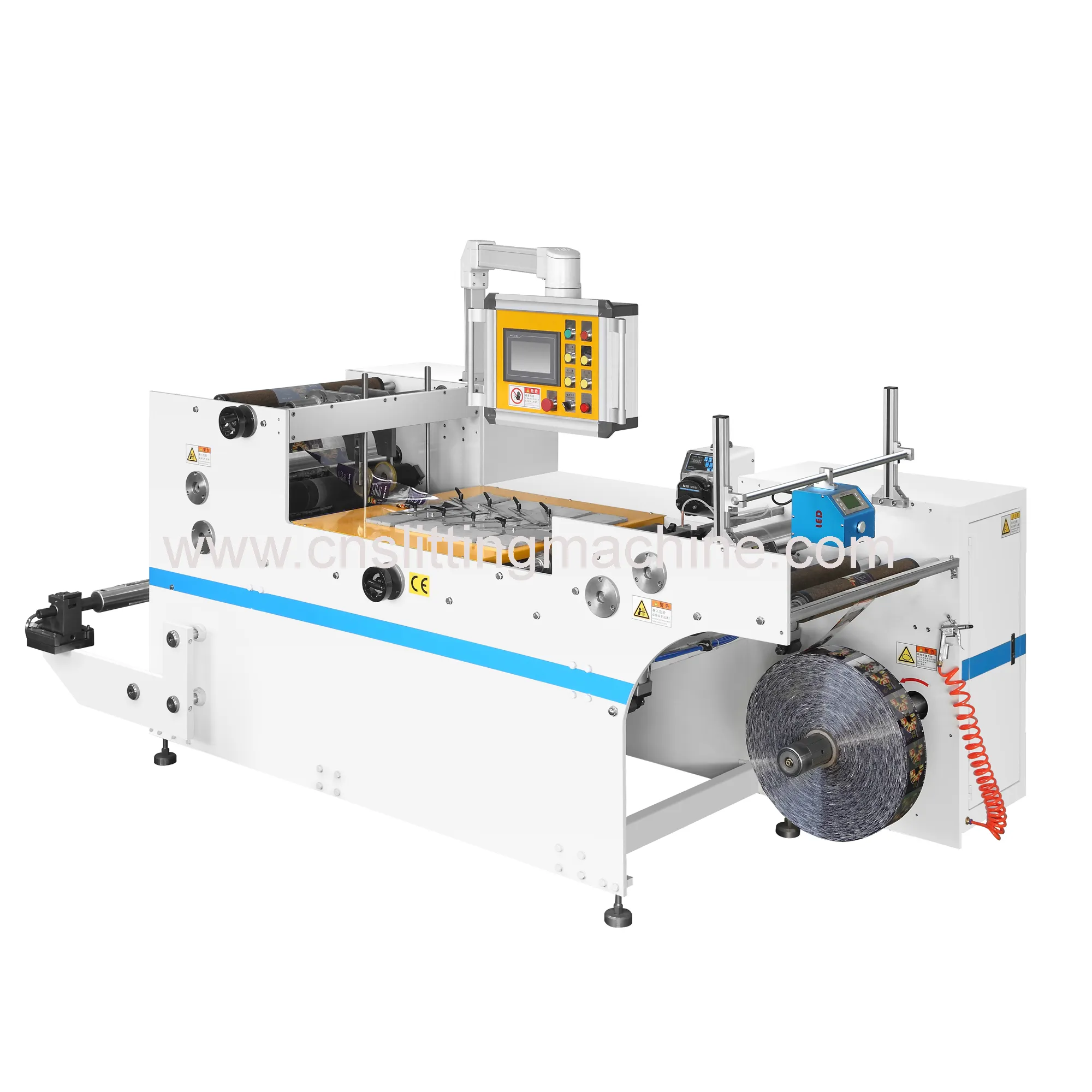

Feeding Group

It is composed of a feeder box that controls the tension of the label feeding and a feeder rack above the electric eye rack group where the label is turned and positioned to convey the label film material.

Cutter set

Built-in blade, planetary pairing method and deflection crankshaft-type steel structure to cut the shrink film.

Electric box

Use well-known brand electrical components, such as Siemens, Schneider, Mitsubishi, ABB etc.

Conveyor Belt

Use the frequency converter to adjust the conveyor belt speed to match the speed suitable for the production capacity.

Related Products

Features of sleeving labeling machine

1. Designed for full-body sleeve labeling applications

2. Touch-control screen and an advanced Programmable Logic Computer (PLC)

3. Easy operation and quick change-over

4. 304 stainless steel and anodized aluminum

5. Acrylic interlock door

6. Accommodates a

wide range of label roll sizes

7. Management setting with password protection

8. Multi-Alarm settings, through buzzers and flashing lights, alert the operator about various errors (e.g., bottle jams, bottles falling, labels running out, etc.)

Heat Steam Shrink tunnel

Tunnel provides the support for making hot sleeves which can be readily wrapped on products or containers. The tunnels are available with different mechanisms which can be chosen based on the wrapping material and its compatibility with the type of heat produced inside the tunnel. Consumers can choose hot steam tunnel or electric heat tunnels as per the labeling material texture and compatibility.

Steam Generator

The steam pressure is 3.5 bar, then open the steam hand valve to about 45 degrees, let the steam shrinking furnace heat up, and observe the temperature gauge on the shrinking furnace at 95-100 degrees.

PVC Shrink Labels

PET Shrink labels

Specification

Technical Parameter | ||||||||

Model | PM-150 | PM-250 | PM-250D (Double Heads) | PM-300 | ||||

Capacity (On the base label length :500ml) | 250 bottles/min | 250 bottles/min | 300 bottles/min | |||||

Label heights | 30~250mm | 30~250mm | 28~125mm | 28~125mm | ||||

Bottle diameter | 28~125mm | 28~125mm | 28~125mm | 28~125mm | ||||

Thickness of label | 0.03~0.13 mm | 0.03~0.13 mm | 0.03~0.13 mm | 0.03~0.13 mm | ||||

Label material | PVC/ PET | PVC/ PET | PVC/ PET | PVC/ PET | ||||

Machine weight | 550KG | 600KG | 950kg | 950kg | ||||

Overall machine size (mm) | 2100x850x2100 | 2100x850x2100 | 2100x850x2100 | 2100x850x2100 | ||||

Product packaging

Company Introduction

ZHANGJIAGANG PAIMA PACKAGING MACHINERY CO., LTD

Paima packaging is located in Zhangjiagang city, the transportation is convenient, which is close to Shanghai, Wuxi City. Paima packaging is a professional manufacturer, consists of R&D, production and marketing in one unit. We have 3 factories in China. One machine factory, and two printing factories.

Our main business is packaging machines and printed labels. One-stop packaging service can save your time and energy. About machine: sleeve labeling machine, sticker labeling machine, opp labeling machine, shrink wrapper, case packer and so on. About labels: PVC/PET shrink labels, adhesive sticker labels, OPP/BOPP labels, printed PE shrink film and so on.

We are specialized in packaging machine (water & beverage filling and labeling machinery, film shrinkage packing machines) and printed labels(shrink label and adhesive labels), we have been in this line for 15 years, and we are also one of the leaders and trustworthy suppliers in this industry.