Термоформовочная Машина из ПЭТ-пластика с тремя станциями для лотков

- Категория: Оборудование для производства пластиковых изделий >>>

- Поставщик: Shanghai,Yiyou,Electromechanical,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 178500.26 $* | 187425.99 $* |

| Aug-19-2025 | 177000.78 $* | 185850.85 $* |

| Jul-19-2025 | 148500.68 $* | 155925.29 $* |

| Jun-19-2025 | 174000.42 $* | 182700.20 $* |

| May-19-2025 | 151500.11 $* | 159075.87 $* |

| Apr-19-2025 | 171000.42 $* | 179550.40 $* |

| Mar-19-2025 | 169500.11 $* | 177975.62 $* |

| Feb-19-2025 | 168000.71 $* | 176400.1 $* |

| Jan-19-2025 | 166500.69 $* | 174825.33 $* |

Характеристики

HW-850 Positive&Negative Pressure Three Stations Plastic Thermoforming Machine

WhatsApp/WeChat/Telegram/Zalo: 0086 180 0196 9771 Contact: Hence Hu

Equipment Overview:

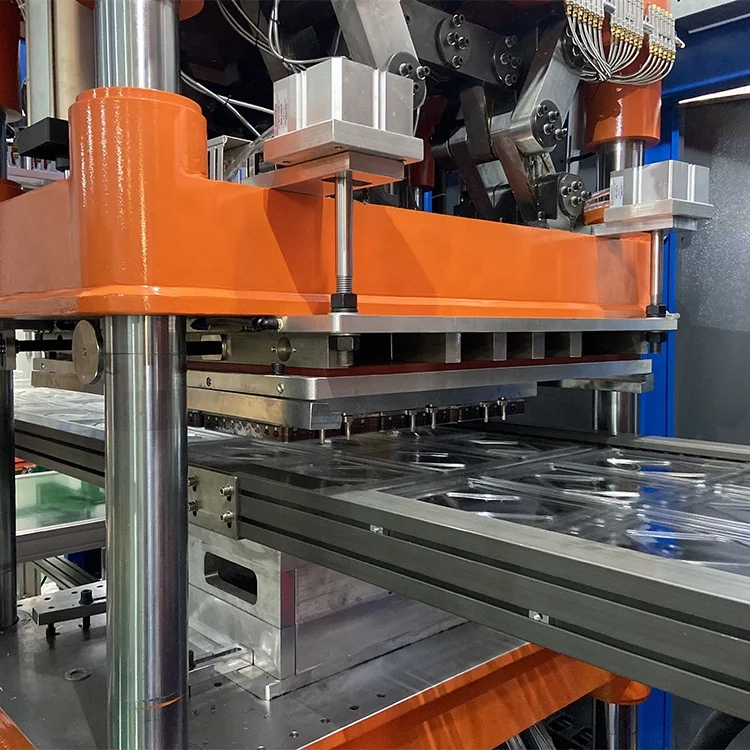

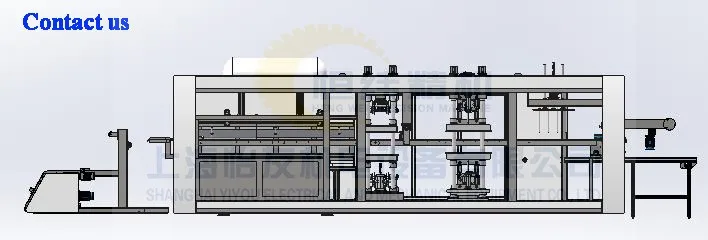

A. Features: HW-850 high-efficiency program-controlled plastic air pressure thermoforming machine, applying the latest international plastic sheet forming technology, is integrated design of machine, electricity and gas, using microcomputer and industrial control programmable PLC control, the entire system HMI. The square tunnel-type imported radiant heater, both concave and convex molds can be formed, laser blade punching, and its process flow: heating, forming, punching, stacking counting and other main multi-station production lines. At the same time, the production line can run simultaneously and synchronously. Using more advanced domestic molding technology combined with foreign countries, it reduces labor, prevents secondary pollution, saves materials, improves product quality and product qualification rate, doubles production efficiency, convenient operation and reliability, strong functionality, high degree of automation, dedicated to the automatic production line of sheet thermoforming and automatic die cutting.

B. Usage: Suitable for the molding of HIPS, PS, PP, PVC, PET, etc. plastic sheets, processing high transparency, high stretch, shallow stretch, round, square, irregular, up and down bidirectional stretching, flanging and other products, producing various boxes, dishes, trays, bowls, covers, industrial packaging, food packaging, cosmetics packaging and other packaging and other plastic products.

Suitable Material | PP, PS, PET, PVC, PLA, etc. | ||||

Suitable Sheet Width | 460-750mm | ||||

Suitbale Thickness of Sheet | 0.15-2.2mm | ||||

Max. Forming Area | 710×850mm for full automatic three stations thermoforming machine | ||||

Min. Forming Area | 420×300mm | ||||

Positive Formed Part Height | 140mm | ||||

Negative Formed Part Height | 130mm | ||||

Servo Motor Power | 32.5KW | ||||

Heating Rated Power | Upper oven: 80kw/Lower oven: 40kw | ||||

Rated power of whole machine | 155KW | ||||

Actual energy consumption | About 40~60KW/H | ||||

Max. Production Speed | 10-25 cycles/minute | ||||

Max. Roll Diameter/Weight | φ900mm/800KG | ||||

Voltage | AC 380V/50Hz (3+N+PE) | ||||

Machine Weight | 12,500kg | ||||

Dimension | L11m×M2.3m×H2.5m | ||||

Equipment cooling water, compressed air, power interface (provided by the buyer)

● Electricity: Three-phase five-wire system 380V power supply: 150KW.

● Air: 1 inch compressed air interface, pressure 0.6-0.8MP.

Customers provide their own air storage tanks, air compressors and refrigeration dryers, etc.

Ambient Conditions:

The minimum width of the equipment entering and exiting the demand side: 3.1m.

The minimum height of the entry and exit of the equipment into the demand side: 3.3m.

The minimum ground load: 600kg/㎡.

The ideal net height of the workshop: 4.8m.

What else products this machine can do?

Clamshell for Food and Vegetable

ESD Electronics Tray

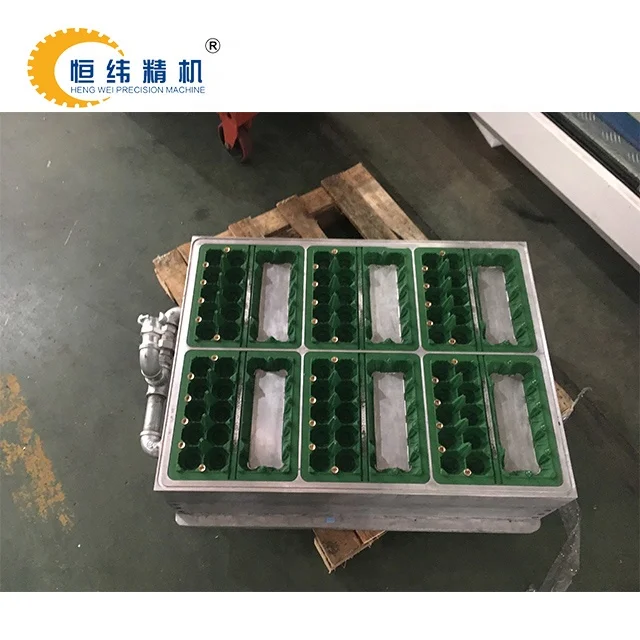

PET Plastic Egg Tray

PS Blister Trays

PP Takeaway Food Box

Memory Card or SIM Card Tray

Our Advantages and Why Choose US;

① We are thermoforming machine factory: located in No.355 of He Peng Road, Bai He Town, Qing Pu District, Shanghai, China (201709). 30minutes away from Shanghai HongQiao Airpot(SHA)! Expressway direct to Shanghai PuDong Airport(PVG)!

② Our engineer has over 15 years experience about plastic and machines.

③ We have richful sources for raw material, moulds and spare parts. Which we can provide the one stop services.

④ Professional shipping team in order to protect machines during loading.

⑤ We are also providing custom thermoforming services in case of the machine cost is out of your budget.

Our Workshop

Shipping and Delivery | ||

Size | L11m×M2.3m×H2.5m | |

Weight | 12,500kg | |

Packing Details | HS Code: 8477409000 Container: 1*40HQ Each parts wrapped with stretch film or wooden crates packing(charge). | |

Contact Details: | ||||||

Contact: | Mr. Hence Hu | |||||

Mobile: | +86 18001969771 | |||||

Whatsapp/Telegram/Zalo: | 0086 18001969771 | |||||

Wechat ID: | hencehu23 | |||||

Facebook: | https://www.facebook.com/hence.hu.thermoforming.machine/ | |||||

QQ: | 375648860 | |||||

Email: | hencehu @hwblistermachine.com(Please remove the space before @ when you input the email address.) | |||||

Website: | www.hwblistermachine.com | |||||

Back to our homepage: | ||||||