Ротационная сушильная машина для куриного

- Категория: Оборудование с барабаном для сушки >>>

- Поставщик: Henan,Baichy,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 66640.98 $* | 69972.73 $* |

| Aug-16-2025 | 66080.30 $* | 69384.19 $* |

| Jul-16-2025 | 55440.9 $* | 58212.67 $* |

| Jun-16-2025 | 64960.80 $* | 68208.89 $* |

| May-16-2025 | 56560.96 $* | 59388.50 $* |

| Apr-16-2025 | 63840.4 $* | 67032.56 $* |

| Mar-16-2025 | 63280.57 $* | 66444.25 $* |

| Feb-16-2025 | 62720.82 $* | 65856.16 $* |

| Jan-16-2025 | 62160.94 $* | 65268.9 $* |

Характеристики

Working Principle of Rotary Dryer Machine

Rotary dryer is consists of a large, rotating cylindrical tube, usually supported by concrete columns or steel beams. The dryer slopes slightly so that the discharge end is lower than the material feed end in order to convey the material through the dryer under gravity. Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer. When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls.

| Model | Weight(t) | Volume(m³) | Capacity(t/h) | Power(kw) |

| 2.2x16 | 38 | 60.8 | 3-5 | 22 |

1) Ore: ore,slag,mineral power,limestone, quartz, fluorite powder,iron ore,metal ore concentrates, metal tailings,etc.

2) Metal: metal powder, iron powder, iron filings, steel scrap, copper filings, etc.

3) Chemical industry: gypsum powder of desulphurization gypsum stir-frying half water model and building gypsum powder,clay,diatomaceous earth, kaolin,bauxite

4) Coal: raw coal,coal slime, coal,coal ash,coal cinder

5) Sand: sand,quartz sand,moulding sand,river sand

6) Various crystals: light calcium carbonate, activated clay, magnetic powder, graphite, mineral mud, clay, lime slurry, ore slurry, phosphorus slag, aluminum red mud, feldspar powder, fly ash, blue carbon, potassium, sodium, calcium, barium and alkali metal or silicate minerals in the

alkali metal.

7) Wood: sawdust, small wood chips, wood veneer.

8) Fertilizer: compound fertilizer, organic fertilizers, inorganic fertilizers, ammonium sulfate fertilizer

9) Agriculture: straw, grass, turf.

10) Animal manure: chicken manure, duck manure, cow dung, etc.

2. chicken manure rotary dryer structure:

♦ Chicken manure rotary drum dryer is mainly composed of rotary part, lifting board, transmission part, supporting part and seal ring.

Chicken manure rotary drum dryer produced by our company uses reasonable running parameters, and the coal and electricity consumption is reduced by over 10-15% and the output per machine is improved by over 10-15%, so that it has been widely used in the cement plants and ore beneficiation plants.

♦ Gear Material: Cast steel

♦ Discharging way: Downstream

♦ Drum Material: Heat-resisting steel sheet

Note:

• Before the installation, the place and the devices to be installed must be checked, in order to avoid other problems during the installation.

• The check should be made in the positional deviation of the pouring quality and size of the base concrete.

• The appearance should be clean without pollution, dust or sundries, The basic size and position of deviation shall meet the following requirements: the position between the size of appearance and the basic coordinates.

• The error between the vertical and the horizontal axis should be less than 20mm, with the different plane elevation errors less than 20 mm; the error size of inclination should be less than 20mm.

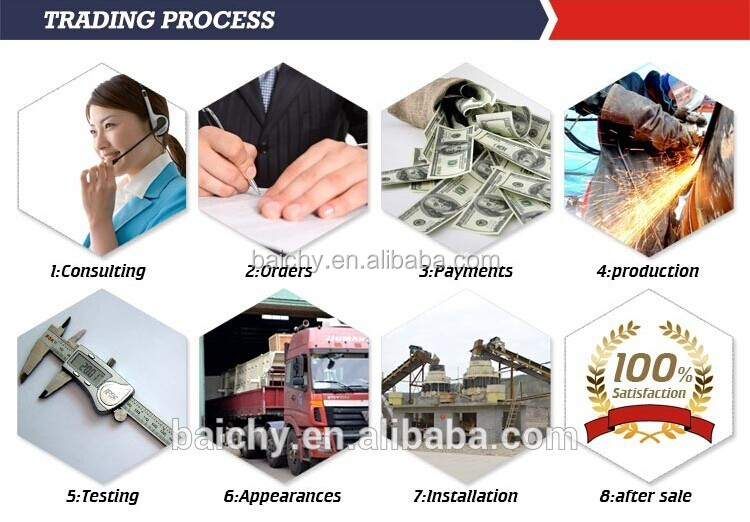

Our payment terms:

1. We usually accept T/T, L/C,

2. We take pictures of finished products before delivery.

Ways of packing:

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Delivery:

1.Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc. and train shipping is also available.

2.We will remind you before boat arrival

Pre-sales Service:

1.The wide product range enables us to provide our customers with stand-alone machines or complete processing plants;

2.Based on our customers'request and budget, our experts make efficient, reliable solutions;

3.Before placing the order every customer has the chance to visit daiwo working machines or complete plant in the site;

4.We have a full set of testing equipment, to provide a good test environment.

After-sales Service:

1.Experienced technicians guidance and engineers will be dispatched to the quarry site to help install the customers'plants;

2.Provide necessary training about machine daily maintenance to local workers ;

3.After-sales department has well-trained employees and professional installation engineers.

Introduction Of Company

Henan Baichy Machinery Equipment Co., Ltd:

1. Entered the filed of wining accessories more than 13 years .

2. Fast delivery ,Leading technology excellent quality ,Reasonable price &Thoughtful service.

3. Special packing ,like Standard package, Nude packing ,Wooden box etc.

4. It has now over 300 employees, including more than 20 middle & senior technical personnel staff.

5. 13 years experience. CQC,SGS,CSSA certified workshop.

6. Main Products:

PE jaw crusher, JCE European jaw crusher , PCX high-efficiency fine crusher , PF impact crusher ,PY cone crusher, CS cone crusher, VSI vertical shaft impact crusher, ZSW vibrating feeder, YK circular vibrating screen, XSD sand washing machine, belt conveyor, YGM high pressure suspension mill etc.

7. It sticks to the development concept of “quality first ,honest & credible , and double-win ”.

Q: What’s your original raw material ?

A: Such as limestone , cobble , granite , etc.

Q:How is the Instalation ?

A:At the client’s request, Baichy can provide installation Technicians to supervise and assist in the assembly and commissioning of the equipment. Travel and accommodation costs, plus US$50 per day per man to be met by the client.

Q:What about the Payment ?

A:30% by TT as deposit on signing the contract, 70% by as final payment of balance after the client’s satisfactory inspection of the equipment prior to the goods leaving the Baichy factory.

Q: What about Warranty? what will we do if the machine is broken down?

A: The warranty period for all of Baichy ’s structural and mechanical equipment is one year. The warranty period for all electric motors is half one year. Wear parts are not covered by warranty unless the component part is found to be flawed.

Q: What should we need to do for if we want to get a best quotation?

A: Hi, if you want us recommend a suitable type for you ,please let us know as follows:

1).the capacity (tons per hour )

2).output size

3).stone type

Q: What could you help me to do for the business ?

A: Many thanks for your trust , we can provide you with proposal chart for complete production lines spot inspection and operator traning according to your demands and the conditions of applied spot , we can help you choose the right equipments ,drilling rig ,loader ,trucks ,excavators and so on .

In order to recommend the suitable models and supply more complete quotation for you, Send your Requiry Details in the below!

Include:

1. Which machine do you need?

(such as crusher, grinder, vibrating screen, vibrating feeder, belt conveyor and other benefication equipment)

2. Which kind of material you are going to process?

Soft stone (dolomite, limestone and others) or hard stone (granite, basalt, river pebble and others) ?

3. What's the production capacity you want?

How many tons or cubic meters per hour?

4. You want only a machine or a complete production line?

And please tell me your email and phone, I will give you factory price with full specification and you will know all details about machine and discount.