Hot selling Dog Food Meat Strip Extruding Line cheap Snacks Machine for

- Категория: Pet Food Processing Machines >>>

- Поставщик: Jinan,Darin,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 47600.30 $* | 49980.42 $* |

| Aug-15-2025 | 47200.41 $* | 49560.69 $* |

| Jul-15-2025 | 39600.19 $* | 41580.97 $* |

| Jun-15-2025 | 46400.0 $* | 48720.56 $* |

| May-15-2025 | 40400.83 $* | 42420.56 $* |

| Apr-15-2025 | 45600.72 $* | 47880.68 $* |

| Mar-15-2025 | 45200.83 $* | 47460.42 $* |

| Feb-15-2025 | 44800.53 $* | 47040.56 $* |

| Jan-15-2025 | 44400.31 $* | 46620.59 $* |

Характеристики

Products Description

Introduction

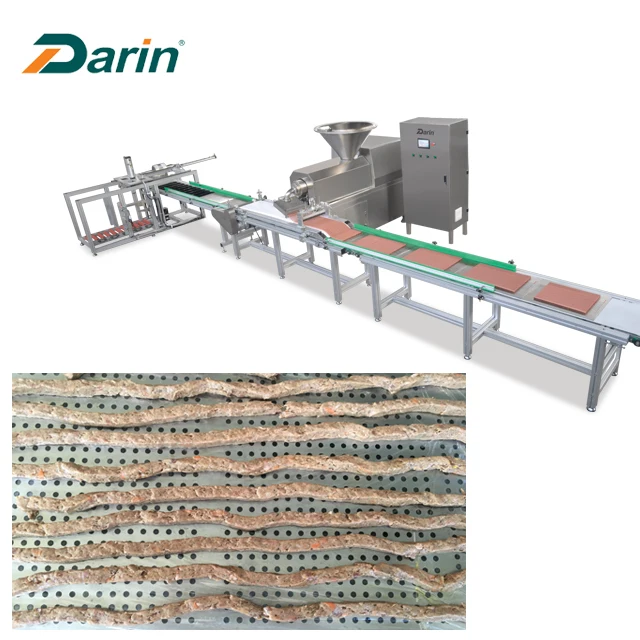

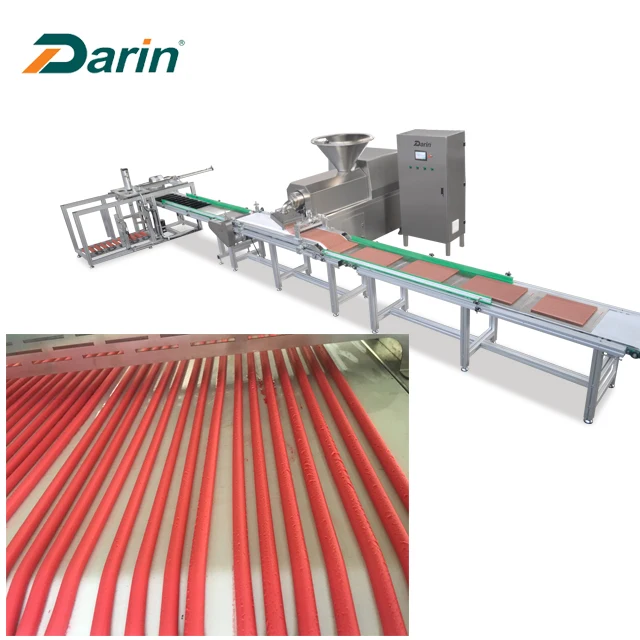

Auto meat strip machine can make pet munchy stick with different sizes and shapes. It includes the following two parts:

1. Auto traying system

Automatic tray system mainly is used for providing continuous individual tray to meat strip machine. To make products which produced by meat strip machine be cut according to tray’s dimension and automatically enter into tray, it is convenient for subsequent baking link . It can automatically pick and place tray through mechanical arm, equipped with tray store. With very high auotmation, can heavily save cost and manual labor intensity .Two layers belts design, meat strip comes on upper belt, and trays comes on nether belt. Top quality photoelectric sensors ensure meat strip and tray exactly matches each other, precisely length cutting control, labor saving, suitable for high standard meat strip producing. Whole system is composed by trays storage, trays picking up, trays conveying, auto cutter, etc.

2. Meat strip extruding machine

DR-126 meat strip extruding machine can extrude multi pieces of meat sticks. Different sizes and shapes can be made by changing the mold.Specially used to produce high content (max 100%) meat products.Patented design to produce meat strip with different shapes and sizes. Siemens motor, FATEK PLC, ABB or Schenider main electric parts.Stainless steel control cabinet, touch screen with friendly interface and fault display function.The screw adopts detachable structure, and has rust-proof treatment.The cylinder should be changed every 2-3 months. During production, cylinder pressure should be no more than 0.6Mpa.

Parameter of Auto Meat Strip Traying System

Machine | Auto meat strip machine | ||||||

Capacity | 200-300kg/hr | ||||||

Air source | 0.5-0.8Mpa | ||||||

Air Comsumption | 90L/min | ||||||

Quantity of Placing Tray One Time | 30pcs | ||||||

Weight | 3000kg | ||||||

Power | 18kw | ||||||

Dimension | 8630x3570x685mm | ||||||

Details Images

Company Profile

Certifications

Why Choose Us

Product packaging

Fumigation wooden cases, which are well sealed and strong enough for long-term trip, and suitable for multi-times loading and unloading by forklift.

Transport

Commissioning And After-sales Service

1.We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, water supply, gas power, material storage, final storages, worker’s restroom, etc.

2.After delivering machines to client’s factory, we start to apply for the Visa to client’s country immediately; normally the vessel needs 20-60 days to the required port, so we have enough time to get the Visa. While the machines arrives your factory , our engineers are ready to start for the commissioning service.

3.1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4.Our engineers have responsibility to train and teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line.

5.It normally costs 10 days for the commissioning service, and we supply 1 year guarantee from the date of completion of

commissioning service.

6.The engineer’s round-trip flight tickets, accommodation and daily salary are on client’s account.

Favorable comments

FAQ

Q: Why us Darin?

Darin: With more than 20 years experience in designing and manufacturing food machines, Darin feels proud and onfident to introduce our machines to you and your esteemed company as one of the most competitive supplier in this business. What we strive to do all the time is providing innovative machines for our customers.

Q: What materials Darin adopted in those machines?

Darin: All the parts that touched with Darin will use food grade SS304, PU belt, strong carbon steel or appointed material for the bearing parts. High quality electronic components supplied by well-reputated company like Siemens and WEG.

Q: How to get a proper quotation with good price?

Darin: Contact us directly and provide as more information as you can, like the product pictures, weight, capacity, voltage and frequency of the motor requested, delivery date if there's urgently need. Quotation will be sent to your inbox immediately once everything is clear.

Q: When will the machines be shipped?

Darin: Normally around 45 working days.

Q: How about the after-sales service?

Darin: Darin will always provide best full-life after sales service, no matter when customers have any problem or questions, we will reply them very soon.