Раскладной цилиндр двойной винт экструдер для пищевых продуктов от производителя поставщик домашних

- Категория: >>>

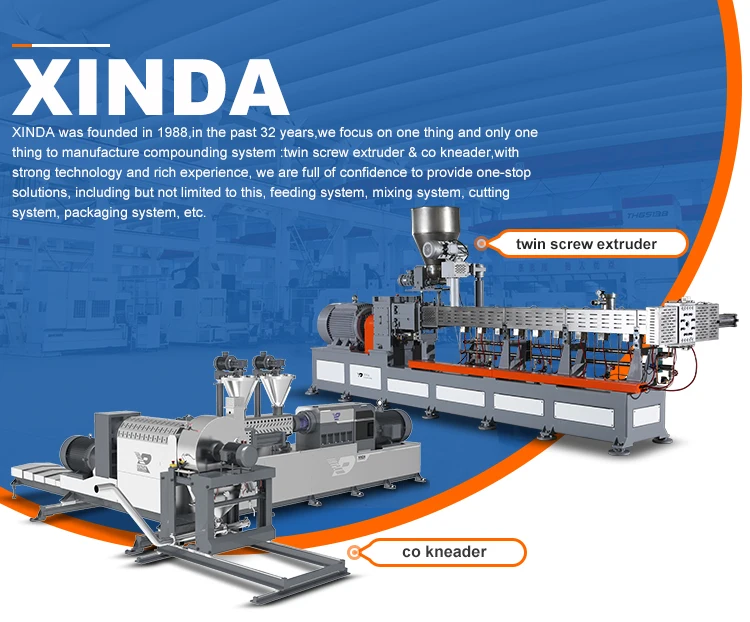

- Поставщик: Jiangsu,Xinda,Tech,Limited

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.68 $* | 0.86 $* |

| Aug-15-2025 | 0.44 $* | 0.88 $* |

| Jul-15-2025 | 0.3 $* | 0.62 $* |

| Jun-15-2025 | 0.19 $* | 0.1 $* |

| May-15-2025 | 0.33 $* | 0.15 $* |

| Apr-15-2025 | 0.0 $* | 0.29 $* |

| Mar-15-2025 | 0.14 $* | 0.20 $* |

| Feb-15-2025 | 0.57 $* | 0.83 $* |

| Jan-15-2025 | 0.49 $* | 0.6 $* |

Характеристики

![]()

Gerneral Characture of XINDA's Co-rotating Twin Screw Extruder/Plastic Extruder

Modular construction

XINDA’s twin screw extruder/Plastic Extruder are built on a modular system. Screw elements with different length and function are mounted to the main splined shaft. The screw combination are changeable. Thus, with a few screw elements and barrel variation, different processing tasks can be finished on the same machine. Besides,when part of screw element,liner or barrel wear out, we only need to replace the broken parts instead of replacing the whole screw or barrel. Maintenance cost saves!

Temperature Separately controlled

The modular principle of the barrel permits precise sequencing for each application. Each barrel section’s temperature can be set separately. Normally,electrical heaters provide heating, cooling is obtained with water. Barrels, as well as screw and kneading elements are made out of nitride steel in the standard version; the wear resistant version is made of suitable materials, corresponding to the respective requirements.

Standard barrels

The freely selectable order of screw elements assure the process sections mating the process configuration. Thus, different process zones can be set up interchangeably, according to the requirements for: Conveying;Kneading; Mixing and shearing; Homogenizing; Degassing; Pressure building.

XINDA's Patent Design!!! Clamshell Barrel

The barrel of twin screw extruder can be opened in minutes.This makes product changeover, maintenance and research fast and easy.

Model No. (Clamshell Barrel) | PSHJ-20 | PSHJ-35 | PSHJ-50 | PSHJ-65 | PSHJ-75 | PSHJ-95 |

Model No. (Fixed Barrel) | SHJ-20 | SHJ-35 | SHJ-50 | SHJ-65 | SHJ-75 | SHJ-95 |

Screw Diameter (mm) | 21.7 | 35.6 | 50.5 | 62.4 | 71 | 91 |

Central Distance (mm) | 18 | 30 | 42 | 52 | 60 | 78 |

L/D | 28-52 | 28-52 | 28-52 | 28-52 | 28-52 | 28-52 |

Motor Power (KW) | 4-5.5 | 22-45 | 75-110 | 110-185 | 160-280 | 180-335 |

Max.Screw Speed: (rpm) | 600 | 600 | 600 | 600 | 600 | 600 |

Output Torque per Shaft (N.m) | 32-43 | 175-358 | 597-875 | 875-1472 | 1273-2228 | 1432-2825 |

Reference Output (kg/h) | 1-20 | 20-80 | 50-200 | 150-350 | 300-600 | 600-1500 |

![]()