Фиксированная роторная сушильная машина высокого

- Категория: Rotary Drying Equipment >>>

- Поставщик: Henan,Shibo,Mechanical,Engineering,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.43 $* | 0.70 $* |

| Aug-17-2025 | 0.15 $* | 0.64 $* |

| Jul-17-2025 | 0.12 $* | 0.90 $* |

| Jun-17-2025 | 0.39 $* | 0.64 $* |

| May-17-2025 | 0.10 $* | 0.39 $* |

| Apr-17-2025 | 0.9 $* | 0.54 $* |

| Mar-17-2025 | 0.47 $* | 0.48 $* |

| Feb-17-2025 | 0.4 $* | 0.61 $* |

| Jan-17-2025 | 0.31 $* | 0.62 $* |

Характеристики

Brief Introduction |

Rotary dryer, also named rotary drum dryer, has the features of wide application, convenient operation and high running rate. While drying, hot gas transfers heat to materials and evaporates the moisture; meanwhile, under the effect of ventilating device, the drying materials are upgraded continuously to discharge the moisture. |

Applied Materials and Application Ranges |

Rotary dryer is widely used to dry the materials such as ore, coal ash, slag and clay in building materials, metallurgy, chemical industry and cement industry. |

Structure |

It is mainly made up of the rotor, stuff-raising plate, transmission device, support device and seal rings. |

Performance Features |

1. Strong ability of anti-overloading, large capacity, low fuel consumption, low drying cost.

|

Working Principle and Structure |

The wet materials to be dried will be sent to the silo by belt conveyor or bucket elevator, then fed to the dryer feeding end by feeder, and the feeding pipeline slope should be larger than the natural slope of the materials so as to make the materials go into the dryer smoothly. |

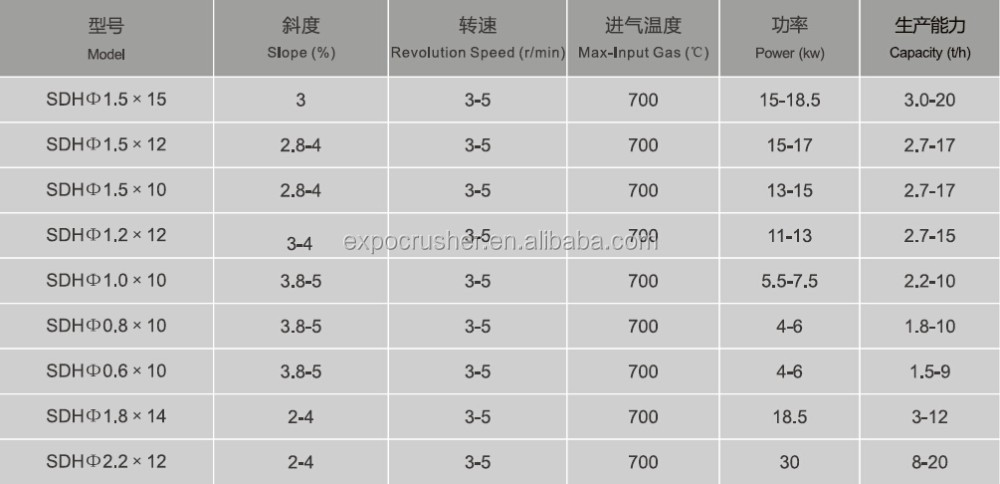

Technical Parameter |

Notice: Any change of technical parameter will not be noticed additionally. |

Details |

|

Spare Parts |

|

Pre-sales

a. Help customers to choose product.

b. Freely send engineers to the working field to plan the installation site and design the best technical production process.

c. Design the special product according to the contract.

On-sales

a. Inspect every part of machines before production.

b. Deliver goods on schedule according to the contract.

After-sales

a. Send the engineers to guide the installation.

b. Install and adjust the equipment for customers.

c. Train the operator for customers.

d. We also provide the technical service for our customers after the installation.

e. If there is any problem during the application, our after-sale engineer shall ensure to offer clear solutions within 24 hours or arrive at the working site within 48 hours ASAP.

Business Scope

Our main products include:

Stone crusher series: jaw crusher, impact crusher, cone crusher, etc.

Mobile crushing station: mobile jaw crusher, mobile impact crusher, mobile cone crusher.

Sand-making equipment series: VSI-IV sand-maker, PCL sand-maker, sand-washer, etc.

Beneficiation equipment series: flotation machine, spiral classifier, rotary dryer, etc.

Grinding mill series: ball mill, raymond mill, etc.

Feeding and screening equipment series: vibrating screen, vibrating feeder, etc.

Accessory equipment: belt conveyor, bucket elevator, screw conveyor, etc.

They are widely used in the fields of metallurgy, mine, chemical industry, building materials, coal, refractory materials, ceramic, etc. Besides, our products are also exported to more than 30 countries, such as Uzbekistan, Denmark, Turkey, Vietnam, Nigeria, etc.

Why Choose Shibo Company

a. We are factory (Not Dealer)

b. We have our own factory & land (Not Renting)

c. Staff reside in factory (Stable Workforce)

d. Perfect pre-sale, on-sale and after-sale services.

In order to give you a responsible and accurate quotation and recommendation of the machine, please inform us of the following information:

a. What is the raw materials you are going to crush?

b. What is the size of the raw materials?

c. What is the final granularity of the materials you are going to achieve?

d. What is the production capacity you are going to get?

e. What do you want? Only a set of jaw crusher, or a complete crushing production line?