TPS гибочная машина письма канала модель

- Категория: >>>

- Поставщик: Hangzhou,Taipusheng,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 18207.91 $* | 19117.1 $* |

| Aug-15-2025 | 18054.5 $* | 18957.65 $* |

| Jul-15-2025 | 15147.73 $* | 15904.33 $* |

| Jun-15-2025 | 17748.22 $* | 18635.12 $* |

| May-15-2025 | 15453.50 $* | 16226.35 $* |

| Apr-15-2025 | 17442.45 $* | 18314.80 $* |

| Mar-15-2025 | 17289.36 $* | 18153.0 $* |

| Feb-15-2025 | 17136.17 $* | 17993.47 $* |

| Jan-15-2025 | 16983.11 $* | 17832.80 $* |

Характеристики

TPS Technology at APPP EXPO SHANGHAI 2019

TPS Technology at Sign China expo Shanghai 2018

TPS Technology at FESPA BERLIN 2018

TPS Technology at APPP EXPO Shanghai 2018

Product Name:S8710 Automatic Channel Letter Bending Machine

Automatic channel letter bending machine model TPS-S8710 is updated on the model S8700 precision automatic channel

letter bending machine and adds a function bending for special aluminum profile of Super Letters. It is a high grade equipment as your first selection bending for LED letters, Super Letters, stainless steel letters, letters with punching holes, resin letters, etc.

Advantage of the equipment:

Front feeding straightening mechanism straightenning curved materials in advance for users in the process of material handling or use the reel material lead to nature bending deformation, to ensure that unstraight mateirals won''t be stuck during processing.

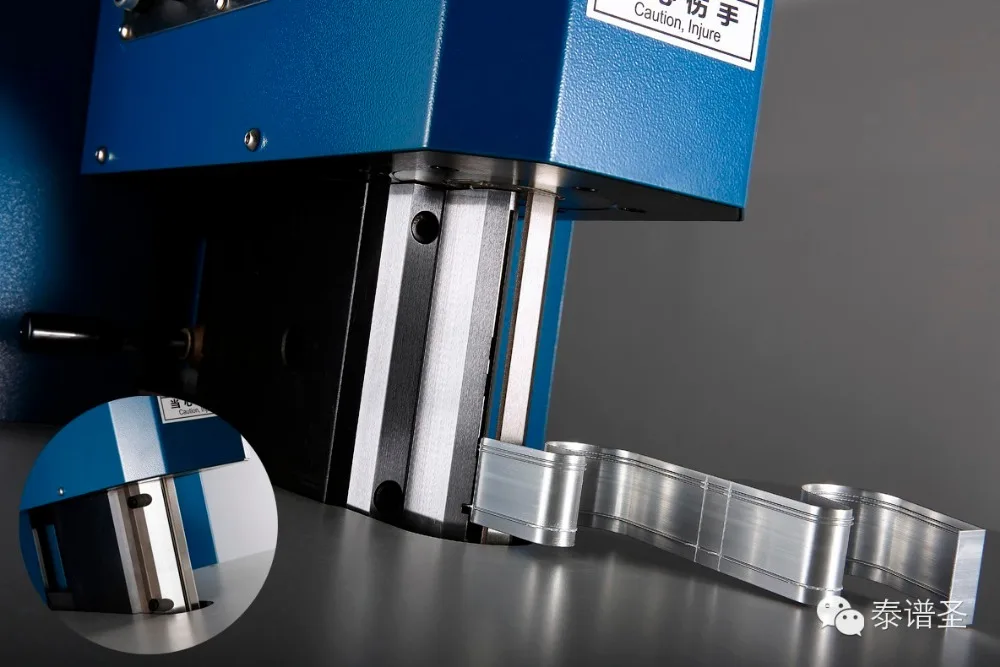

The clamping alternating conveying mechanism is composed of two groups of cylinder clamping device, by linear guide, synchronous belt, tension adjusting mechanism, deceleration strengthening mechanism and large torque step motor cooperate closely to achieve high precision feeding, to eliminate the slippage of the roller type feed physics and indentation phenomenon caused by the stress.This machine components manuafactured with high recision, assemble complex, difficult to control. This mechnism is only fit for high-end equipment.

The function of punching for removing strip of aluminum profile and V slotting type can completely solve problems of bad forming with traditional channel letter bending machine and small arc adjusted manually difficultly. It makes processing smoothly and quickly like bending for plain material. Using the blade for slotting the aluminum profile at positions of punch-removed strip.

And the blade cutting point can be grinded wider a little bit to avoid aluminum profile broken off easily during bending.

In order to meet bending requirement for SUPER LETTERS with high quality and high accuracy, it uses the bending tool quick

change system which can be changed quickly and independently between plain material and special aluminum profile for

SUPPER LETTERS.

On basis of the alternating double bending bars system, It is added a bending bar specially for aluminum profile making for

SUPPER LETTERS that can realize processing for plain material and the aluminum profile in one machine. And it improves thebending forming without indentation almost on material surface.

Software advantages:

Software for operating and controlling the machine is researched and developed by our own engineer team. There is a special

function that Sharp angles can be retracted to avoid base letters can not fixed into bended letters due to CNC router can not cut

inner sharp angle shapes same as original letter file because of cutting tool radius. It doesn’t need to adjust manually to

reduce the staffs production skills and improve production efficiency.

The machine is including the software for counting cost of making SUPER LETTERS. The software can calculate the volume

and the ratio of resin filling grease automatically and aluminum profile cost according to its graphic. It will be easier to check

production cost and reduce waste.

Different property material and different material thickness make different springback. TPS controlling system of software can

adjust bending power for different material easily and quickly during shifting material based on our further research. We just

need to adjust a parameter of ArcCompensate on user parameters page for same property material with different width and

different thickness. And parameters for corresponding material can be saved with data base. Users can select corresponding

data for corresponding material to bend without complicated adjusting.

Face letter size cut by laser cutting machine is not same exactly as letter graphic of file due to the matter of laser point radius.

TPS software has a function to calculate laser wastage and compensate automatically with a simple step. It helps users to

avoid graphic processing again and again to solve the problem of laser wastage and improve production efficiency.

Built-in various surround types for making letters:

Different surround type should be zoomed correspondingly for its graphic and calculate material wastage. Built-in various

types for making letters realize making different types of bending letters without any complicated matching calculation to make

processing easily.

Operating software updates free all life.

Software support:

DXF/PLT files input, support CAD, TYPE3, CRELDREW, ILLUSTRATOR, etc.

Samples:

Technical Paremeter:

| Power supply: | AC200V |

| Power | 2.2KW |

| Compressed air | 0.4—0.8MPa |

| Control axis quantity | 4 Axises |

| Min. Bending radius | R7mm |

| Min. distance between interior angle and exterior angle | 4.5mm |

| Bending distance from start | 3mm |

| Applied Material | Stainless steel,galvanized sheet,aluminium coil; one type of aluminum profile for making supper letters |

| Material thickness | 0.6-1.0mm for flat tape, 1.0mm for aluminum profile |

| Processing height | 20-110mm |

| Material feeding method | Altermate feeding |

| Servo Motor | 2PCS |

| Step motor | 2PCS |

| N.W. | 400Kg |

1UNIT channel letter bending machine S8700 packed in a poly-wooden case. total measurement is 1.83cbm, G.W.: 480kgs

Operating software updating lifetime free.

Best Service with professional, high-efficiency and considerate.