Термоформовочная пластиковая машина для производства цветочных горшков PP

- Категория: Оборудование для производства пластиковых изделий >>>

- Поставщик: Shanghai,Yiyou,Electromechanical,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 41650.57 $* | 43733.10 $* |

| Aug-19-2025 | 41300.20 $* | 43365.19 $* |

| Jul-19-2025 | 34650.28 $* | 36383.27 $* |

| Jun-19-2025 | 40600.22 $* | 42630.61 $* |

| May-19-2025 | 35350.18 $* | 37118.16 $* |

| Apr-19-2025 | 39900.86 $* | 41895.99 $* |

| Mar-19-2025 | 39550.94 $* | 41528.65 $* |

| Feb-19-2025 | 39200.27 $* | 41160.43 $* |

| Jan-19-2025 | 38850.80 $* | 40793.53 $* |

Характеристики

Full Automatic Air Pressure Cup/Bowl/Dish/Plate Plastic Thermoforming Machine

WhatsApp/WeChat/Telegram/Zalo: 0086 180 0196 9771 Contact: Hence Hu

Equipment Overview:

HW-730 series automatic hydraulic cup making machine is a new generation of equipment developed based on our company's years of mechanical manufacturing experience. It is mainly suitable for the processing of PP, PE, PS, HIPS, PET, PVC and other plastic sheets products. The process is to heat the processed plastic sheet to the process temperature of the corresponding material to form it under positive(air) pressure to form various cups, boxes, bowls and other thin-walled containers, such as milk cups, jelly cups, ice cream cups, disposables drinking cups, instant noodle bowls, fast food boxes, food boxes, etc.

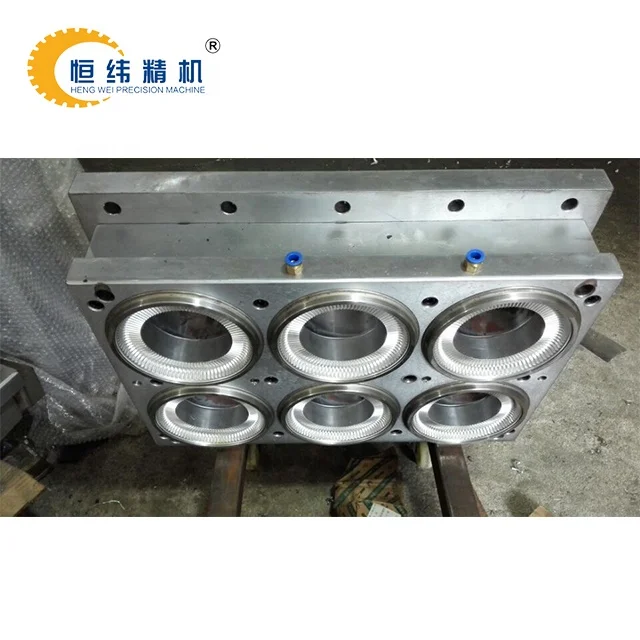

The equipment is mainly composed of thermoforming unit, unwinding and conveying, waste winding unit and electrical control unit. It adopts a stable hydraulic drive system and an electric drive system for joint control, which has the advantages of stable operation, low noise, strong clamping force, and high degree of automation. By replacing and installing different molds or mold cores, products of different models and specifications can be produced to achieve the purpose of one machine with multiple uses, which greatly improves production efficiency.. Our machine adopts domestic and foreign well-known brand electrical components and pneumatic components to make it run stably, with reliable quality and long service life.

The design of the equipment is advanced and unique. The processed thermoplastic sheet is heated and placed on the mold, quickly stretched and compressed with air to make the sheet close to the mold cavity to form, and the product is automatically blown out after being cut. The whole machine has a compact structure, stretching and compressed air combine the functions of stretching, forming, cutting, cooling, and blowing out the finished product into one working cycle, so that the product processing time is short, the finished product is high grade, and it meets the national health standards.

According to customer product requirements, we recommend different equipment to pick up the finished product.

Model Number | HW-680 | HW-730 | HW-750 | HW-856 | |||

Suitable Material | PP、PS、PE、PET、PVC、ABS、PLA (biodegradable material) etc. | ||||||

Sheet Thickness | 0.3-2.0mm | ||||||

Sheet Width | 680mm | 730mm | 750mm | 850mm | |||

Max. Forming Area | 680*350mm | 730*420mm | 750*500mm | 850*560mm | |||

Max. Forming Height | ≤140mm | ≤180mm | ≤180mm | ≤180mm | |||

Working Speed | 20-35 cycles/minute(depends on sheet thickness) | ||||||

Heating Power | 70KW | 100KW | 110KW | 137.2KW | |||

Main Motor Power | 7.5KW | 11KW | 15KW | 15KW | |||

Power Supply | 380V/50HZ | ||||||

Air Pressure | 0.6~0.8Mpa | ||||||

Air Consumption | 3200~4000 L/min | 4000~5000 L/min | 4500~6000 L/min | 6000~8000 L/min | |||

Water Consumption | 40-45L/min | 40-50L/min | 40-60L/min | 40-80L/min | |||

Dimensions(mm) | 3500*1600*2300 | 3950*1600*2300 | 4300*1600*2300 | 4500*1650*2300 | |||

Weight | 4500kg | 5500kg | 6000kg | 6200kg | |||

According to different product characteristics and different customer requirements, our machines have two different stretching methods. They are servo motor drive and air cylinder drive.

Our Advantages and Why Choose US;

① We are thermoforming machine factory: located in No.355 of He Peng Road, Bai He Town, Qing Pu District, Shanghai, China (201709). 30minutes away from Shanghai HongQiao Airpot(SHA)! Expressway direct to Shanghai PuDong Airport(PVG)!

② Our engineer has over 15 years experience about plastic and machines.

③ We have richful sources for raw material, moulds and spare parts. Which we can provide the one stop services.

④ Professional shipping team in order to protect machines during loading.

⑤ We are also providing custom thermoforming services in case of the machine cost is out of your budget.

Shipping and Delivery | ||

Size | L3950*W1600*H2300mm | |

Weight | 5,500kg | |

Packing Details | HS Code: 8477409000 Container: 1*40HQ Each parts wrapped with stretch film or wooden crates packing(charge). | |

Contact Details: | ||||||

Contact: | Mr. Hence Hu | |||||

Mobile: | +86 18001969771 | |||||

Whatsapp/Telegram/Zalo: | 0086 18001969771 | |||||

Wechat ID: | hencehu23 | |||||

Facebook: | https://www.facebook.com/hence.hu.thermoforming.machine/ | |||||

QQ: | 375648860 | |||||

Email: | hencehu @hwblistermachine.com(Please remove the space before @ when you input the email address.) | |||||

Website: | www.hwblistermachine.com | |||||

Back to our homepage: | ||||||