Вакуумная Термоформовочная Машина PP ABS HDPE PC

- Категория: Plastic Vacuum Forming Machines >>>

- Поставщик: Shanghai,Yiyou,Electromechanical,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.42 $* | 0.97 $* |

| Aug-17-2025 | 0.89 $* | 0.98 $* |

| Jul-17-2025 | 0.12 $* | 0.39 $* |

| Jun-17-2025 | 0.66 $* | 0.35 $* |

| May-17-2025 | 0.68 $* | 0.22 $* |

| Apr-17-2025 | 0.23 $* | 0.78 $* |

| Mar-17-2025 | 0.27 $* | 0.97 $* |

| Feb-17-2025 | 0.97 $* | 0.53 $* |

| Jan-17-2025 | 0.24 $* | 0.74 $* |

Характеристики

Contact WhatsApp 0086 180 0196 9771 to get know more info.

| Product Name: Heavy gauge thermoforming machine |

|

| Forming Area: 1000*1500mm, 1500*2500mm, 2000*3000mm. | |

| Forming Depth: Max. 600mm | |

| Cycle Speed: 3-8 minutes per cycle | |

Suitable Material: ABS,PP,PS,PVC,EPS,HIPS, PE,HDPE, PMMA,EVA,PETG etc. | |

| Material Thickness: 2-12mm | |

| Air Pressure: 0.6-0.8Mpa | |

| Vacuum Pump Flow: 100m³/h or 200m³/h | |

| Air consumption: 5m³/h | |

| Water consumption: 0.2m³/h | |

| Power supply: 380v/50hz | |

| Lower die maximum load: 18,000KG |

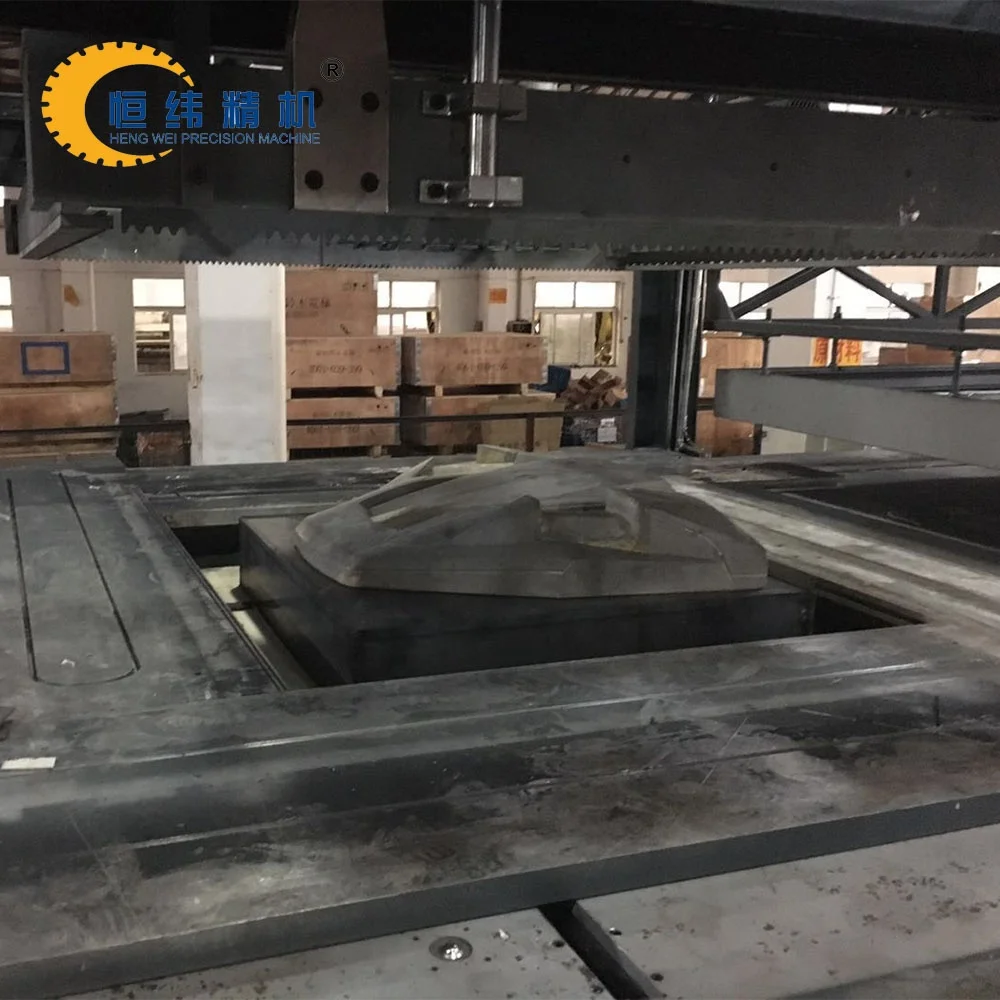

The heavy gauge thick sheet vacuum forming machine is a key process equipment for making plastic molded plastic parts by vacuum forming process. It uses thermoplastic sheet material as raw material, is heated by oven to softening temperature, and then passes through plastic sheet. The vacuum negative pressure between the plastic forming mold and the plastic forming mold adsorbs the plastic sheet in the thermoplastic state on the working surface of the plastic forming mold and then cools the molding.

According to the forming area can be divided into:

(1) Small thick sheet thermoforming machine, the forming area is about 1500mm*1000mm or less.

(2) Medium-sized thick sheet thermoforming machine with a forming area of 1500mm*1000mm to 2500mm*1500mm or less.

(3) Large-scale thick film thermoforming machine with a molding area of 2000mm*3000mm or above.

Sectors:

- Car interior and exterior

- Transportation

- Building materials

- Packaging

- Medical instruments

- Household appliances

- Sporting goods

Our Advantages:

- European design, intelligent control, lightweight.

- Halogen heating tubes with individual temperature controllers for precise setting, energy saving.

- Movable Windlow Plate can adopt to different size of sheet, save material cost.

- Full servo motor machine drive, precision, stable and energy saving.

- Easy operating and maintenance.

| No. | Main electronic component | Brands |

| 1 | PLC | Delta(Taiwan) |

| 2 | Touch Screen | Delta(Taiwan) |

| 3 | Eliminator | From Japan |

| 4 | Cylinder | ZhiCheng |

| 5 | Electromagnetic Valve | From Taiwan |

| 6 | Vacuum Pump | Elmo Rietschle |

| 7 | Replay | From Japan omron |

| 8 | Sheet Temperature Detector | Japan OPTEX |

| 9 | Cooling Fan | 0.75KW from China |

| 10 | Frequency Converter | Delta |

| 11 | Photocell | Japan Omron |

| 12 | Heater | Tianbao |

| Note: We accept machine configuration customized, Please consult us in advance if you need it. | ||

Contact Supplier We are looking forward to work with you! | ||

| Contact Person: | Mr. Hence Hu |  |

| Email: | hencehu@ hwblistermachine.com | |

| WeChat: | hencehu23 | |

| WhatsApp: | 0086 18001969771 | |

| Mobile: | +86 18001969771 | |

| Skype: | a375648860 | |

| Facebook: | https://www.facebook.com/hence.hu.thermoforming.machine | |

| Youtube Chanel: | https://www.youtube.com/channel/UC8305a3lE7WgPDbMtrjZ60w | |

| Our Address: | No.355 of HePeng Road, BaiHe Town, QingPu District, Shanghai, China | |

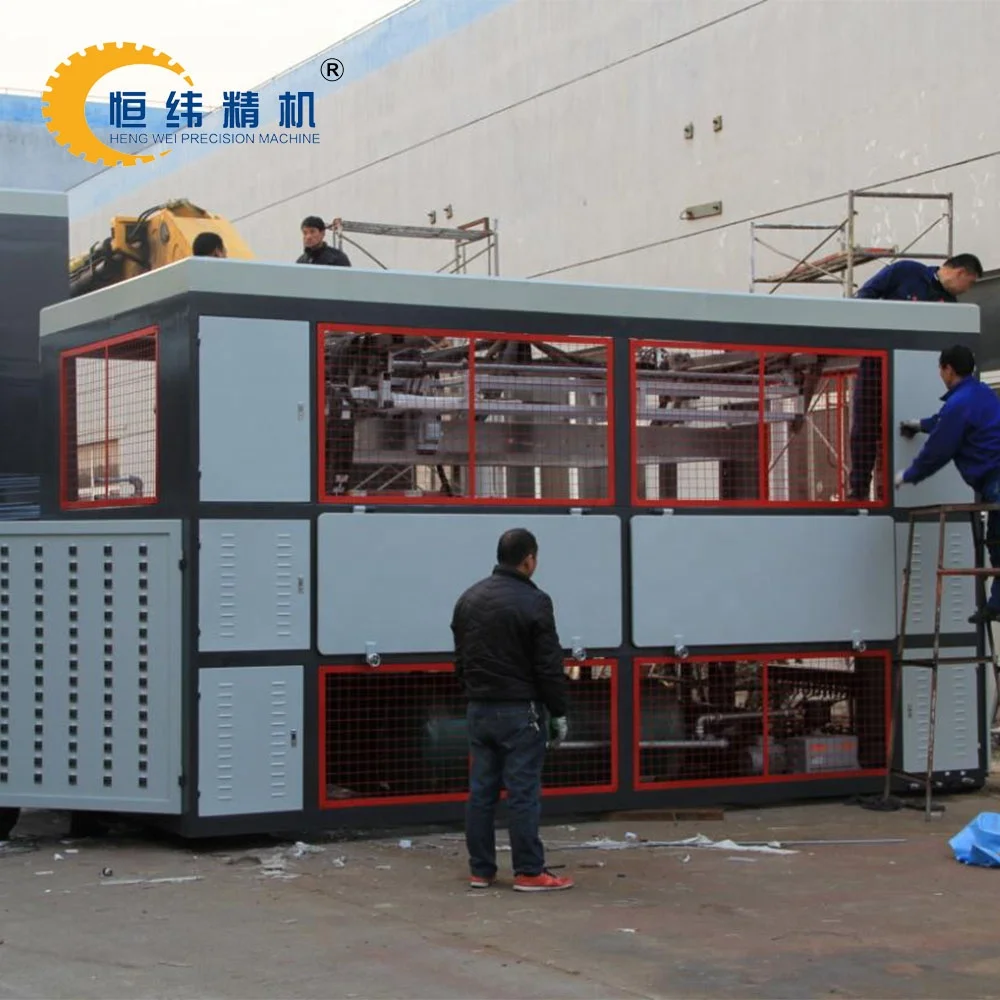

We are working in 2500 m2 production area and still looking for expand, operate with a team of 30 expert staff and R&D department, presenting innovative solutions at a favourable price, has now grown into a position to export to 4 continents and 15 countries so far.

We have a very good professional loading and unloading team, the team has more than ten years of professional loading experience, and serves the delivery tasks of many Fortune 500 companies in Shanghai. The team has a range of forklift trucks ranging from 5 tons to 100 tons, which can be fully qualified for delivery of various type of our thermoforming machine. Moreover, every time we put the machine into the container, we will also use the imported professional fixing rope to firmly fix the machine in the container, which can effectively avoid the machine damage caused by the collision of the machine at sea.

Shanghai Yiyou having entered the thermoforming industry as a manufacturer in 2010, Yiyou has been among the industry leaders with fully automatic air pressure and vacuum thermoforming machines, semi-automatic vacuum forming machine, thick sheet vacuum thermoforming machine and plastic cup thermoforming machine. Our machines are produced with high quality and performance in mind.

Through our efforts over these years, we have accumulated more than 20 countries customer in our service. Under our meticulous service, all customers have a very high evaluation of our vacuum forming thermoforming machine quality and our services. And many customers have purchased a lot of equipment after the first purchase.

Our company is located in Shanghai, the economic capital of China. The factory is located in Suzhou, only 40 minutes by drive. Shanghai has very convenient transportation, and all countries around the world have direct flights to Shanghai. This is convenient for customers who want to purchase our equipment in the future if they want to inspect the machine or after-sales service. Moreover, Shanghai is China's quality capital, because all Shanghai products enjoy international reputation, because if we do not control the quality of the plastic thermoforming machine, we can not stand in Shanghai!

Quality is our culture, We build a brand with soul!!!