4 миллиона квадратных метров в год машина для производства

- Категория: >>>

- Поставщик: Hebei,Lvjoe,Machinery,Manufacturing,Group,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 17850.53 $* | 18743.72 $* |

| Aug-15-2025 | 17700.43 $* | 18585.40 $* |

| Jul-15-2025 | 14850.48 $* | 15593.57 $* |

| Jun-15-2025 | 17400.55 $* | 18270.47 $* |

| May-15-2025 | 15150.91 $* | 15908.56 $* |

| Apr-15-2025 | 17100.53 $* | 17955.44 $* |

| Mar-15-2025 | 16950.88 $* | 17798.19 $* |

| Feb-15-2025 | 16800.56 $* | 17640.17 $* |

| Jan-15-2025 | 16650.50 $* | 17483.18 $* |

Характеристики

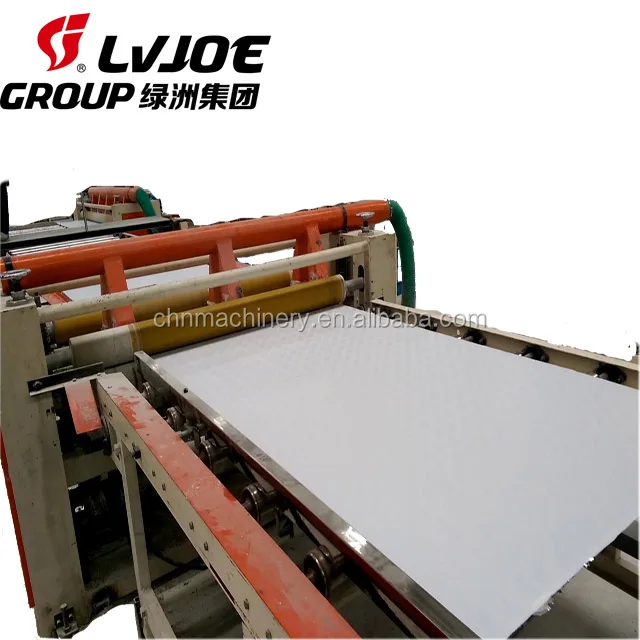

4million square meters per year Gypsum ceiling board lamination making machine/perforation machine/punching machine

The lamination machine is used to stick decorative films like PVC film, aluminum foil, wood grain etc with gypsum board or MDF, PVC foam board, etc

The finished PVC gypsum ceiling tile is made of paper-faced gypsum board with a layer of PVC on surface and aluminum foil on its back. It is a environmental friendly, light weight, high quality, fireproof, waterproof and corrosion-resistant decorative ceiling board. It can be widely used in high fireproof and waterproof requirement environment, such as hotel, hospital, school, house and factory etc.

Flowchart (some of the parts are optional)

Automatic board feeding--aluminium foil lamination--pvc film lamination--lengthwise cutting--horizontal cutting--edgeTapping--stretch packing-- finished products stacking

Main Features

1) Fully automatic, semi automatic, manual for your choice.

2) Adopting world famous brand Siemens PLC control system.

3) High capacity of 2-8 million sqm per year.

4) Raw materials: Gypsum board, PVC film, Aluminum foil, PVAC glue, tape

5) Effective laminating width: Max 1300mm

6) Sheet thickness: 5--30mm

7) Laminating speed: Max 15m/min

8) Finished board size: 600*600mm, 595*595mm, 603*603mm

About the machine:

metal plate is punched by the machine, and form perforated mesh with different hole shape.

As long as changing the mold, we can meet the different needs of customers. A lot of guests use

it for decoration or foot pedal.

The raw materail: stainless steel board, aluminum board, cold and hot steel board,

copperplate and fiberboard,plastic board and so on.

Hole shape: long square hole, square hole, round hole,triangle hole, hexagonal hole, the plum blossom hole,ichthyosisthe hole,scale hole and other different kinds of hole,The company can

process the different kinds of type accroding the customer order.

Punching MachineTechnical Parameter:

1, Punching pressure: 160 KG.

2, Punching stroke: 30mm.

3, Max gypsum board punching thickness: 20mm.

4, Total weight: 7,000 KG.

5, Punching speed: 1 board/m in 50 times/min (1220mm*2400mm)

Good effection for perforating: the holes are Smooth, clean, burr, and vertical.

You can choose the shape of the hole as your requirement, about the operation, our worker can teach you how to use it.