Машина для резки гипсокартона/Высококачественная автоматическая линия по производству ПВХ ламинированного

- Категория: Оборудование для изготовления досок >>>

- Поставщик: Hebei,Lvjoe,Machinery,Manufacturing,Group,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 238000.41 $* | 249900.36 $* |

| Aug-15-2025 | 236000.70 $* | 247800.55 $* |

| Jul-15-2025 | 198000.1 $* | 207900.4 $* |

| Jun-15-2025 | 232000.74 $* | 243600.37 $* |

| May-15-2025 | 202000.30 $* | 212100.79 $* |

| Apr-15-2025 | 228000.88 $* | 239400.41 $* |

| Mar-15-2025 | 226000.55 $* | 237300.54 $* |

| Feb-15-2025 | 224000.52 $* | 235200.90 $* |

| Jan-15-2025 | 222000.36 $* | 233100.34 $* |

Характеристики

PVC Laminated Gypsum Ceiling Tile Making Machine Good Price

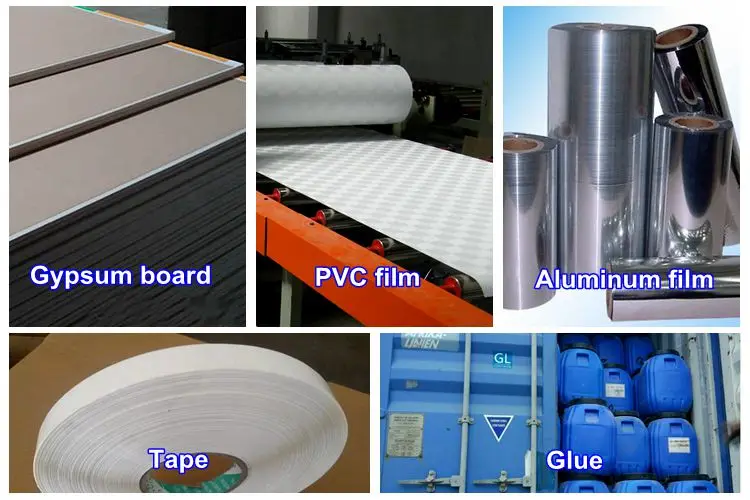

The lamination machine is used to stick decorative films like PVC film, aluminum foil, wood grain etc with gypsum board or MDF, PVC foam board, etc

The finished PVC gypsum ceiling tile is made of paper-faced gypsum board with a layer of PVC on surface and aluminum foil on its back. It is a environmental friendly, light weight, high quality, fireproof, waterproof and corrosion-resistant decorative ceiling board. It can be widely used in high fireproof and waterproof requirement environment, such as hotel, hospital, school, house and factory etc.

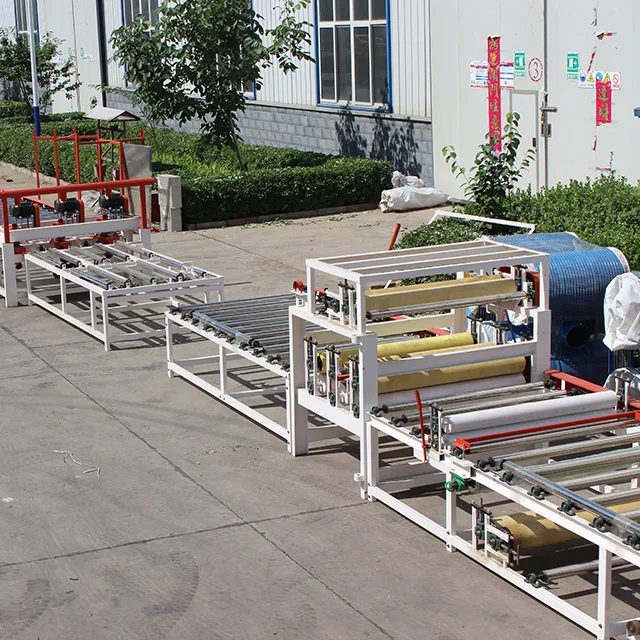

Flowchart (some of the parts are optional)

Automatic board feeding--aluminium foil lamination--pvc film lamination--lengthwise cutting--horizontal cutting--edgeTapping--stretch packing-- finished products stacking

Main Features

1) Fully automatic, semi automatic, manual for your choice.

2) Adopting world famous brand Siemens PLC control system.

3) High capacity of 2-8 million sqm per year.

4) Raw materials: Gypsum board, PVC film, Aluminum foil, PVAC glue, tape

5) Effective laminating width: Max 1300mm

6) Sheet thickness: 5--30mm

7) Laminating speed: Max 15m/min

8) Finished board size: 600*600mm, 595*595mm, 603*603mm

gypsum board laminated cutting machine

Product description

This equipment is used to cut the laminated calcium silicate board/ gypsum board/ mgo board from 4'*8' to 2'*2' according to the decorative specification.

First, put the boards on the conveying rollers, then go to the first cutting device. After passing the second cutting device, the board will be formed.

It consists of slitting and crossing-cutting automatic cutting equipment, equipped with the dust exhausting system. In the process of cutting, the electric impulse style dust collector recycles the dust, reaching the purpose of the dust exhausting efficiently.

Technical Parameters:

Raw Material:

Pvc Gypsum Ceiling Board:

Use:

1. Our company has professional installation & debug teams.

We will install and test the production line at the customers' place until the equipment produces the qualified products.

2. We supply the accessories all the year round.

The guarantee time of the equipment is one year.

3. We are responsible for the technical consultation and service all the year around and solve all kinds of technical problems at any time.

4. We can help the customer to do the consignment and the relevant procedure for import and export.

5.If the buyer can not run the machine well then we will send the production engineers to help the buyer to run the machine, and we can cooperate for long terms.