SS-411D пищевой разделитель твердых отходов аппарат для утолщения и обезвоживания

- Категория: Управление отходами >>>

- Поставщик: Jiangsu,Benenv,Environmental,Technology,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 23800.75 $* | 24990.8 $* |

| Aug-17-2025 | 23600.14 $* | 24780.8 $* |

| Jul-17-2025 | 19800.92 $* | 20790.57 $* |

| Jun-17-2025 | 23200.67 $* | 24360.49 $* |

| May-17-2025 | 20200.23 $* | 21210.31 $* |

| Apr-17-2025 | 22800.41 $* | 23940.27 $* |

| Mar-17-2025 | 22600.62 $* | 23730.50 $* |

| Feb-17-2025 | 22400.52 $* | 23520.73 $* |

| Jan-17-2025 | 22200.48 $* | 23310.8 $* |

Характеристики

Products Description

SS-411D food solid waste separator sludge thickening and dewatering machine

Sludge Thickener Dewatering Machine, the clogging of filter mesh decreases the efficiency of conventional dewatering equipment. Such like belt press and filter press. BENENV's KDS Sludge thickner equipment with small footprint is equipped with unique dewatering technology, which enables dewatering while automatically self-cleaning the filter mesh. It is of larger throughput, self-cleaning function by slits opposite continuos rotation, no vibration and noises, and low power consumption. Besides, the strcuture is very simple, so the operation and maintenance is easy.

Its brand new dewatering technology enables automatically self-cleaning for the filter gap during sludge thickening and solid liquid separation. So this machine has stable and constant throughput without need of backwash water to prevent clog. This self-cleaning mechanism enables KDS sludge thickening machine to be an effective machine for oily and grease sludge.

Specifications

Specifications of SS-411D Sludge Thickener Dewatering Machine | ||||||

Dry Solid Capacity | 40~60 kg-DS/h | |||||

Flow Capacity | 3.0-6.0 m3/h | |||||

Gap Size | 1 mm | |||||

Power | 0.4 kw | |||||

Material | SS304 | |||||

Net Weight | 200 kg | |||||

PLC | Schneider | |||||

Advantages

Main Features of SS-411D food solid waste separator sludge thickening and dewatering machine

1) No Clogging and backwash

Solid-liquid seperation and self-cleaning function are carried out simultaneously by oval discs rotation between filtrate gap

2) Stable Treatment capacity

Continuos cleaning process avoids throughput reduction which could easily occur in other dewatering equipments

3) Large Throughput

Smooth rotation of oval discs enables large transportload

4) Easy Maintenance

Due to the simple strcuture, the maintenance is easy

Solid-liquid seperation and self-cleaning function are carried out simultaneously by oval discs rotation between filtrate gap

2) Stable Treatment capacity

Continuos cleaning process avoids throughput reduction which could easily occur in other dewatering equipments

3) Large Throughput

Smooth rotation of oval discs enables large transportload

4) Easy Maintenance

Due to the simple strcuture, the maintenance is easy

Camparison between Sludge Thickening and Dewatering Machine and the other equipments

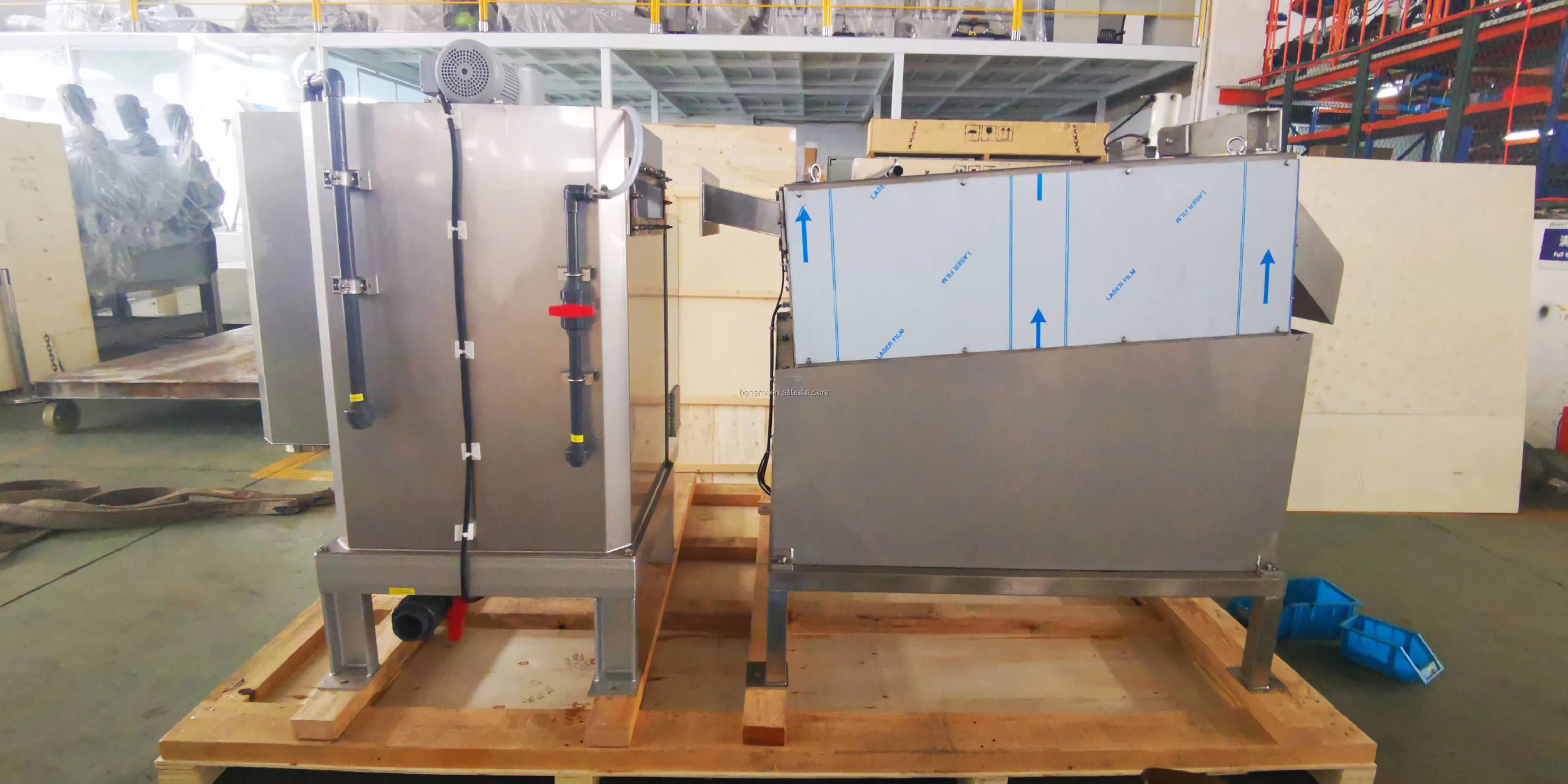

Product Display

Oval discs & Slits

Totally SS 304 oval discs and slits. The sludge moves forward by the rotation of oval discs and the filtrate flows down to the filtrate tank through the slit gaps.

Sludge Outlet

Well aligned sludge outlet, of best Japanese quality control.

Collecting filtrate. SS 304 material

Motor

Japanese brand motor. We also have German origin motor.

Application

SS-411D food solid waste separator sludge thickening and dewatering machine

* Food wastes treatment in school feeding center for scraps of food processing* Fishery wastes treatment

* Crusher drainage waste disposer

* Process before treatment wastewater

* Drain water off devise from food etc.

* Primary filtration for wastes coming from grease traps

* Enrichment screen before dehydration

* Dehydrator

Working Principle

Sludge Thickening and Dewatering Machine Model Reference

Certifications

Exihibitions

Our Company

Jiangsu Benenv Environmental Protection Technology Co. , Ltd. is an environmental protection company,specialized in mechanisms, environmental engineering and other related science. With research center in Japan, we have factory and office in China. Benenv specializes in the design, engineering, supply and installation of domestic and commercial water, waste water and sewage treatment systems, gas pollution control, and other environmental engineering products. Our company possesses complete sets of process design, equipment supply, constructions, and technology innovation. Overall, we are highly qualified in delivering turnkey and BOT projects for any industry. We have abundant experience in the treatment of industrial, domestic and commercial hazard wastewater. Benenv is staffed with local and overseas professionals with more than 15 years of acquired technical expertise and experience, offering various technologies and allied services. Our company works closely with the top 10 universities and scientific institutes to keep our cutting-edge technology and transform science and technology into productivity. Our company also works with the government, and is authorized as the liaison office of Yixing government to perform technology cooperation with foreign countries.

Packaging and Delivery

1. Waterproof packing with the international export standard by 20ft, 40ft, 40hp container. Equipment Fittings, Electric Motor and

Power Cabinet will be packed in Wooden Case or Iron Box. Other Equipment will be packed by Color-Stripes Plastic Cloth.

2. The whole plant machinery size are large as normal, so we will use Waterproof cloth to pack all of them. The motor, gear box or

other easily damaged parts, we will put them into box. We have a professional shipping department, they will try their best to

save your container quantity.

Power Cabinet will be packed in Wooden Case or Iron Box. Other Equipment will be packed by Color-Stripes Plastic Cloth.

2. The whole plant machinery size are large as normal, so we will use Waterproof cloth to pack all of them. The motor, gear box or

other easily damaged parts, we will put them into box. We have a professional shipping department, they will try their best to

save your container quantity.

FAQ

Q: What’s KDS Sludge Dewatering?

A: KDS Sludge Dewatering machine has been used in Japan market for over 30 years, is a mature technology. It was developed in our Japanese research center (Japan Benenv Co., Ltd.). We have Japanese engineers for technical support and quality control, other Chinese manufacturers they are just copy-cats from this Japanese technology, they are not original and lack of experience on this technology.

Q: What type of sludge is KDS Sludge Dewatering applicable to?

A: It is widely applicable to various types of sludge such as solid-liquid separation for oil waste, primary treatment for wastes produced from livestock, crushed wastes collection like plastic, construction sites sludge, purification of lakes and rivers (primary treatment, sediment and sludge treatment),etc.

Q: What’s the application scope of KDS Sludge Dewatering?

A: It is widely applied in Municipal water and wastewater treatment plants, Agricultural/fishery community wastewater treatment plants, Industrial waste treatment plants, Food/beverage production plants, Dairy farming/Meat processing plants, Chemicals manufacturing plants, Machinery manufacturing/Metal processing plants, Paper manufacturing, building material manufacturing, oilfield associated water accompanied with crude oil mining, etc..

Q: What’s the material of KDS Sludge Dewatering?

A: It is Stainless Steel, we choose SUS304H, SUS316L, etc, some key parts we import from Japan, we also have our own workshop in Japan for production.

Q: What’s the equipment used together with KDS Sludge Dewatering?

A: Sludge pump, polymer dosing pump, washing pump, air compressor.

Q: How to choose the right model?

A: Advise us the sludge source, treating capacity, solid content rate, then we could choose the suitable model for you. Please put forward if you have special requirement.

A: KDS Sludge Dewatering machine has been used in Japan market for over 30 years, is a mature technology. It was developed in our Japanese research center (Japan Benenv Co., Ltd.). We have Japanese engineers for technical support and quality control, other Chinese manufacturers they are just copy-cats from this Japanese technology, they are not original and lack of experience on this technology.

Q: What type of sludge is KDS Sludge Dewatering applicable to?

A: It is widely applicable to various types of sludge such as solid-liquid separation for oil waste, primary treatment for wastes produced from livestock, crushed wastes collection like plastic, construction sites sludge, purification of lakes and rivers (primary treatment, sediment and sludge treatment),etc.

Q: What’s the application scope of KDS Sludge Dewatering?

A: It is widely applied in Municipal water and wastewater treatment plants, Agricultural/fishery community wastewater treatment plants, Industrial waste treatment plants, Food/beverage production plants, Dairy farming/Meat processing plants, Chemicals manufacturing plants, Machinery manufacturing/Metal processing plants, Paper manufacturing, building material manufacturing, oilfield associated water accompanied with crude oil mining, etc..

Q: What’s the material of KDS Sludge Dewatering?

A: It is Stainless Steel, we choose SUS304H, SUS316L, etc, some key parts we import from Japan, we also have our own workshop in Japan for production.

Q: What’s the equipment used together with KDS Sludge Dewatering?

A: Sludge pump, polymer dosing pump, washing pump, air compressor.

Q: How to choose the right model?

A: Advise us the sludge source, treating capacity, solid content rate, then we could choose the suitable model for you. Please put forward if you have special requirement.