Автоматическая машина для изготовления птичьих клетки/пневматическая разведения кур/Улучшенный сварщик голубей сварочный аппарат проволочной сетки

- Категория: >>>

- Поставщик: Anping,County,Dechen,Wire,Mesh,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 13090.57 $* | 13745.91 $* |

| Aug-17-2025 | 12980.54 $* | 13629.63 $* |

| Jul-17-2025 | 10890.10 $* | 11435.89 $* |

| Jun-17-2025 | 12760.60 $* | 13398.64 $* |

| May-17-2025 | 11110.79 $* | 11666.13 $* |

| Apr-17-2025 | 12540.1 $* | 13167.12 $* |

| Mar-17-2025 | 12430.27 $* | 13052.9 $* |

| Feb-17-2025 | 12320.47 $* | 12936.47 $* |

| Jan-17-2025 | 12210.12 $* | 12821.20 $* |

Характеристики

Dechen Wire Mesh Machine

Dechen Wire Mesh Machine

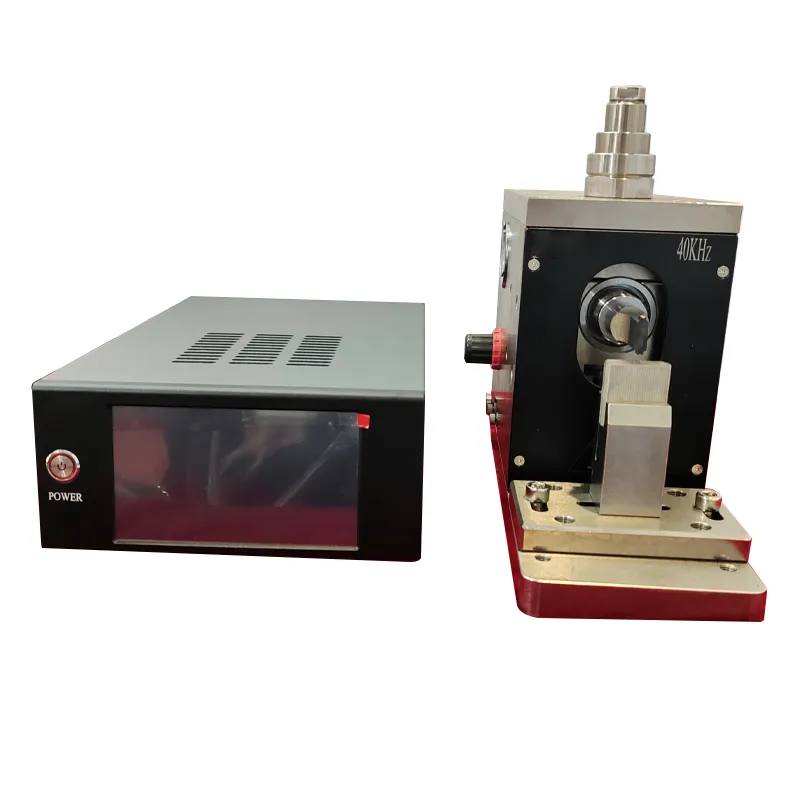

Automatic bird cage making machine/Pneumatic chicken breeding machine/Advanced pigeon cage welder

Specifications

1.Wire diameter: 2-3.2mm

2. Line wire from: coil wire.

Cross wire from: coil wire.

3.Control system :synchronous control with PLC,touch screen board.

4.firm welding, little noise, high speed

5.Finished production: panel mesh

6.Application materials: iron wire, stainless steel wire, galvanized wire, rebar

7. Warranty :Whole year warranty for complete machine,except for consumable parts

Automatic bird cage making machine/Pneumatic chicken breeding machine/Advanced pigeon cage welder is used for fence 2-3.2mm, and it is an automatic equipment designed and manufactured by ourselves absorbing advanced resistance welding technology from home and abroad.

1. The automatic wire mesh welding machine to make cage mesh panel,which welding power comes from the spring. It is easily to control the welding pressure, more over ten times than the traditional hopper.

2. The automatic welding machine to make wire mesh manual uses synchronous control technique, welding time and separate welding adopt Japan, Sonydigital control system which can be input to touch screen control panel to adjust the mesh size, and it can weld different size mesh on the same wire mesh panel.

3.The line wire is inserted with one side of the coil wire into through-hole solder wire mesh machine, and then it continues working automatically.

4.The cross wire feeding is also coil wire from the pay off, through the wire straighteing wheels, then straightened and cut by one small wire straightening and cutting machine.after that, the straightening cross wire will reach the welding place.

5.The CNC pulling mesh system is controlled by the international advanced servo drive mode.which makes the pulling mesh aperture more standard and accurate.

In the lastest design of welding machine, on the both sides of pulling mesh tracks, two pieces of fence mesh are equipped for security and beauty.

6.The mesh panel cutting machine is pneumatic machine, there will be equipment with one set of air pump.When completed of set length mesh, the mesh panel will be cut by the cutter machine under the control of cabinet cabinet. And, one dropping mesh table will be equipped with the mesh cutting machine.

Special type can be customized according to the needs of the clients!

1.Straightening Automatically and Cutting Machine : 1set

2.Wire Tray :welded points number + 1

3.Pneumatic mesh panel cutting machine

(automatic mesh panel cutting machine):1 set

4.Automatic bending machine:1set

5.Air pump:1 set

Pneumatic mesh panel cutter just runs once when needed to cut mesh under desposed an air pump,which is more energy saving than automatic mesh panel cutter!

The finished products can be mesh panel .

Breed aquatic mesh: poultry mesh, pigeon mesh , rabbit mesh, fox mesh and etc.

1. The spare parts and control cabinet will be loaded in wooden box.

2.The main machine is nude packing or plastic packing

Our company aimd at "Clients First,Honest First" .

1.If the buyers need, we can send our technical staff to the buyers factory to install the machine and providing the training in 30 days after the machines arrived the destination port.

2.Maintenance period :one year for whole machine except vulnerable parts

3.The numbers of technical persons: one technician per machine

4.The fees: the buyer have to pay the technical salary 80 USD per day, and the round-trip ticket, accommodation and other related fees.

During the maintenance period , if the parts are broken caused by the product problem, seller will offer the parts for free, if you need we assign the technicians to your factory, then you will pay some related fees.

Anping Dechen Wire Mesh Machine Co,Ltd is located in Anping Hebei Province, which has the largest wire mesh industrial zone in Asia.Our factory is specialised on reinforcement mesh machine, fencing mesh mesh welding machine, wire mesh welder, razor barbed wire machine,wire staightening and cutting machine and so on.

If you are interested in some of our products, please feel free to visit our website or contact us for more information and pictures. As per your needs which are welcome to discuss with us.

We are looking forward to establishing long-lasting business ralationships with in the near future.

Website: http://dechenmachine.en.alibaba.com/

The other machines(click the pictures and get more datails)

Q: How to get an accurate quotation ?

A: 1.Mesh panel wire diameter : from ___mm to ___mm

2.Mesh opening size : from ___mm to ____mm

3.Would you like mesh panel or mesh rolls?

4.Max. Wire mesh width ?