Машина для прессования композитных деревянных опилок машина поддонов

- Категория: Other Woodworking Machinery >>>

- Поставщик: Gongyi,UT,Machinery,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 7497.42 $* | 7872.45 $* |

| Aug-17-2025 | 7434.57 $* | 7806.6 $* |

| Jul-17-2025 | 6237.22 $* | 6549.68 $* |

| Jun-17-2025 | 7308.35 $* | 7673.96 $* |

| May-17-2025 | 6363.46 $* | 6681.48 $* |

| Apr-17-2025 | 7182.52 $* | 7541.45 $* |

| Mar-17-2025 | 7119.51 $* | 7475.96 $* |

| Feb-17-2025 | 7056.97 $* | 7409.64 $* |

| Jan-17-2025 | 6993.69 $* | 7343.34 $* |

Характеристики

Composite wood sawdust pallet press machine/wood pallet block press machine for sale

Description about wood sawdust block press machine

Raw Material → Crusher → Dryer → Sawdust hot press block machine

The whole charcoal production line mainly includes four needed machines: crusher, dryer, and wood sawdust hot press brick machine.

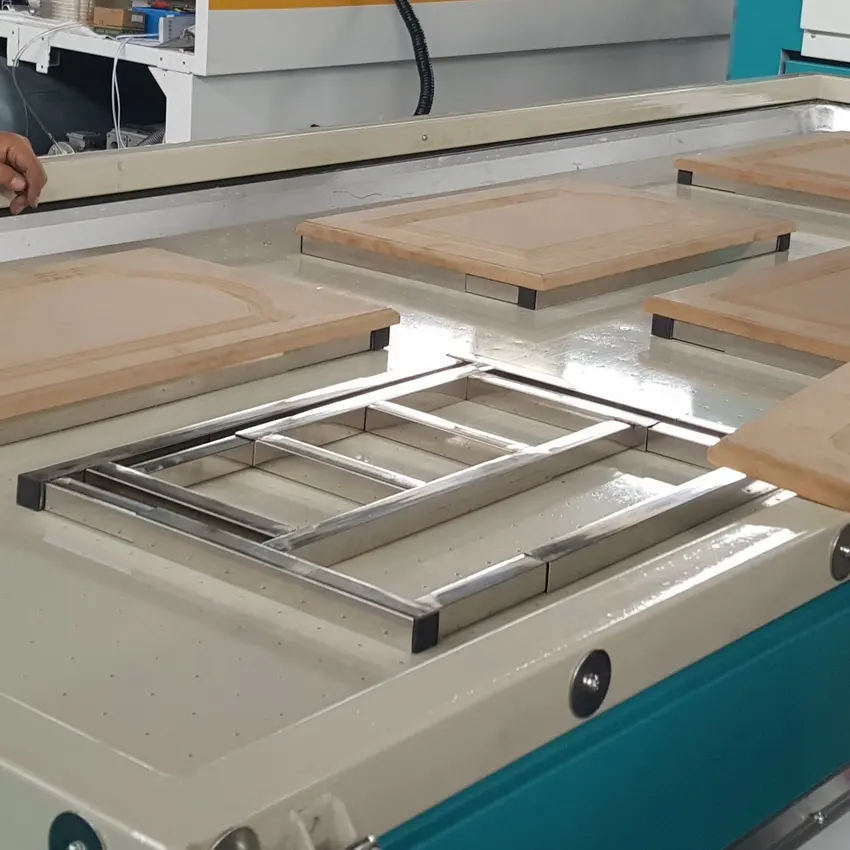

wood block machine can make wood pallet or block from raw materials such as wood

shavings,sawdust,etc

1.The materials size is about 5cm.

2.The materials moisture content within 10%-12%.

3.If the materials can not meet above request, you need crusher and dryer machine.

4.The materials can be wood sawdust, wood chips, wood shavings and other small waste

wood materials.

1. Crusher

Crusher is to reduce the size of raw materials at 3-5mm, which is suitable for making the wood block.

This crusher can crush: small tree branch, cotton stalks, tree bark, coconut shell, rice straw wheat straw, corn straw, grass river reeds, palm husk, soybean stalk or husk, coffee husk, paddy straw, sunflowers stalk, bamboo and many other agrowastes etc. And the whole production line can help you make the materials into the excellent wood fibers, flour and sawdust directly, save energy and high efficiency. So the invested cost of the charcoal making can be zero.

2. Dryer

Air current type dryer is to control the moisture content of raw materials at 8-12%, suitable for making wood block. Too dry or too wet will make the wood blocks loose, can’t have high density. It is professionally designed for drying different kinds of wood sawdust.

The whole system consists of fan blower, motor engine, fuel boiler, steel pipe, cyclone and air lock. In this sawdust dryer machine system, wet material is input into hopper by screw feeder. Fuel furnace

produces large volume of hot air. The hot air is driven into steel pipes, mixed with wet sawdust and moved through curving pipes and drying chamber by the power of fan blower.

Fast moving hot air sustains and is mixed with raw material sent by spiral feeder in the suspending state through the steel pipe; moisture evaporates as the material traverses along the steel pipe and is rendered dry at the discharge end. Humid air is continuously exhausted, thus the material is dried.

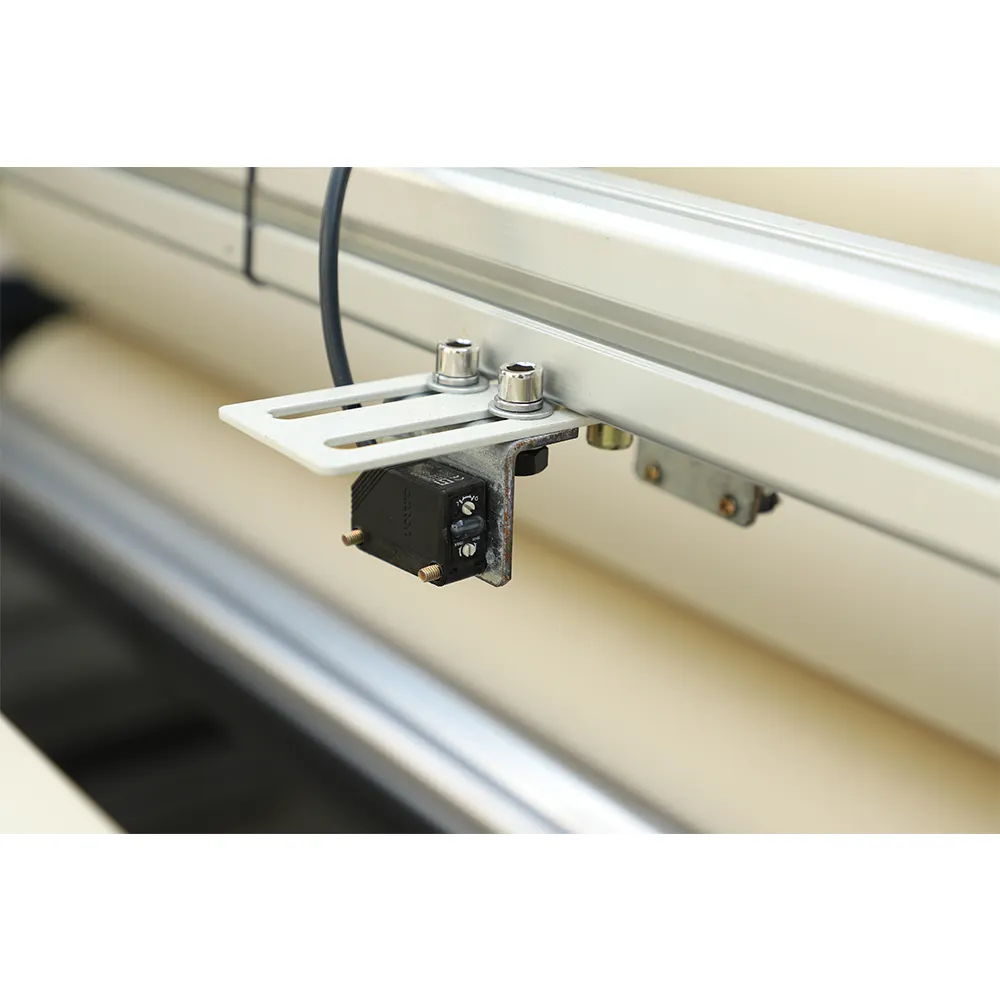

3. Hot press wood block machine

It is a process during which raw materials are compressed under high pressure and high temperature. After the processing of drying and pressing, the wood blocks is characterized by high density, small in size, better combustion.

Model | specification | Weight kg | Power Kw | Capacity M³/24h | ||

Long mm | Wide mm | Hight mm | ||||

50*75 | 4600 | 700 | 1420 | 1000 | 15 | 2-2.5 |

75*75 | 4600 | 700 | 1420 | 1050 | 15 | 2-2.5 |

80*80 | 4600 | 700 | 1420 | 1100 | 15 | 2-3 |

80*100 | 4600 | 700 | 1420 | 1150 | 19 | 3-4 |

90*90 | 4600 | 700 | 1420 | 1200 | 19 | 3-4 |

95*95 | 4600 | 700 | 1420 | 1250 | 19 | 3-4 |

100*100 | 4600 | 700 | 1420 | 1300 | 19 | 3-5 |

The machine length exclude the cutting machine | ||||||

1.Waterproof packing with the international export standard by 20ft, 40ft, 40hp container.

2. Equipment Fittings, Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box. Other Equipment will be packed by Color-Stripes Plastic Cloth.

3. Or as per customer's requirements.

Pre-sale:

1. Suggest to client suitable models of our carbonization furnace, according to the raw material, including its type, huimidity, final charcoal capacity requirements.

2. Introduce machine's structure and features in detail, explain the price component;

3. answer client concerned questions.

After-sale:

1. Start production as soon as receiving down payment.

2. Send photos of machine in manufacturing and finished photos to client, for your better learn about the machine's condition.

3. Delivery machine in time, taking photos during loading, so you can "remote monitoring" your goods.

4. Documents and certificate available in time.

5. Manual documents available. Engineer can be sent to client site for installation instruction.