HW-1220 термопластиковая вакуумная формовочная

- Категория: Вакуум-формовочная машина для пластика >>>

- Поставщик: Shanghai,Yiyou,Electromechanical,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 30940.12 $* | 32487.80 $* |

| Aug-16-2025 | 30680.62 $* | 32214.90 $* |

| Jul-16-2025 | 25740.19 $* | 27027.20 $* |

| Jun-16-2025 | 30160.76 $* | 31668.8 $* |

| May-16-2025 | 26260.52 $* | 27573.4 $* |

| Apr-16-2025 | 29640.1 $* | 31122.76 $* |

| Mar-16-2025 | 29380.94 $* | 30849.72 $* |

| Feb-16-2025 | 29120.37 $* | 30576.4 $* |

| Jan-16-2025 | 28860.74 $* | 30303.52 $* |

Характеристики

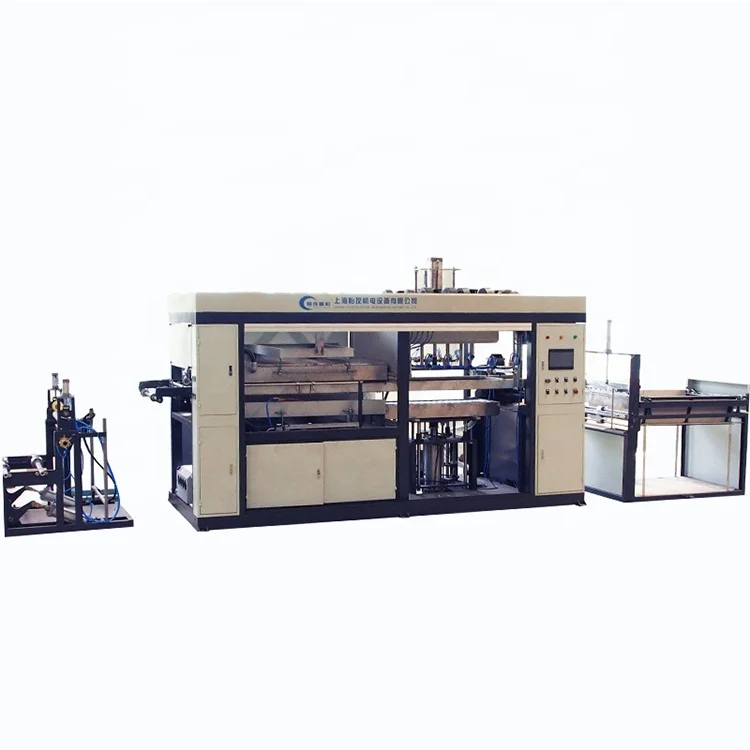

HW-1220 Semi Automatic(Offline Cutting) Plastic Vacuum Thermoforming Machine

WhatsApp/WeChat/Telegram/Zalo: 0086 180 0196 9771 Contact: Hence Hu

Ⅱ. The material enters the material opening, and the film is pulled electrically. Driven by the chain, the material enters the heating section, and the lower brake presses the material.

Ⅲ. The material is heated under the control of the time system. When the heating is reached, the lower gate is released, and when the sheet is driven by the chain to move to the forming area, the lower and upper gates will lock the material from the end to the end, and the mold plate will rise. Then upper mold goes down to contact with the hot plate, and the mold is vacuumed to start blistering.

Ⅳ. The upper mold rises when the upper mold time is up, and the cold air atomized cooling water starts to cool the sheet quickly.

Ⅴ. After the sheet is cooled and solidified, the bottom air begins to demold, and the chassis down, then repeat the previous procedure

Ⅵ. Push the formed sheet to the slitting part, the slitting knife gate will block the material, and the moving knife will cut the material. The material is put into the material box by the film placing device.

The repeated work of the above procedures is the basic process of the fully automatic high-speed blister vacuum forming machine. Please see below working video of machine.

Suitable Material | PP, PE, PVC, PS, PET, ABS, HIPS (biodegraded material PLA) etc. | ||||

Suitable Sheet Width | 450-750mm adjustable | ||||

Suitbale Thickness of Sheet | 0.15-2mm | ||||

Max. Forming Area | 710×1220mm | ||||

Maximum Forming Height | 150-180mm | ||||

Heating Method | Single or double heating oven | ||||

Heating Power | 39-78KW | ||||

Machine Working Speed | 3-8 cycles/min depends on actual product and sheet thickness | ||||

Air Consumption | 1.5m³/minute | ||||

Water consumption | Tap water recycling use | ||||

Actual energy consumption | Rated power 96kw. Normal production power between 30-55kw | ||||

Power Supply | 380V/50HZ | ||||

Temperature control | Voltage adjust by touch screen | ||||

Weight | 3T | ||||

Dimension | 6960*1500*2650mm | ||||

Our equipment advantages:

1. Machine structure: No. 10 flat-through welding is adopted to make the frame stronger, with a pressure resistance of more than 30 tons. And according to the needs, the key parts are connected by bolts, which is convenient for installation, disassembly, maintenance and replacement.

2. Forming mechanism: adopts the overall four-guide column design, and is designed with the cold-plated optical axis and the coaxial mold plate. Thus, the lifting movement is stable, and the lower mold meets the requirements of the sheet material. The size of the mold plate is designed to match the size of the mold. The mold plate adopts the all-aluminum cold water circulating cooling mold plate.

3. Feeding system: It adopts a large feeding rack, which can load 30-300kg/roll at a time, and adopts dual-axis alternate locking technology. The motor has the function of positive and negative rotation, which is convenient for retracting and unloading the film.

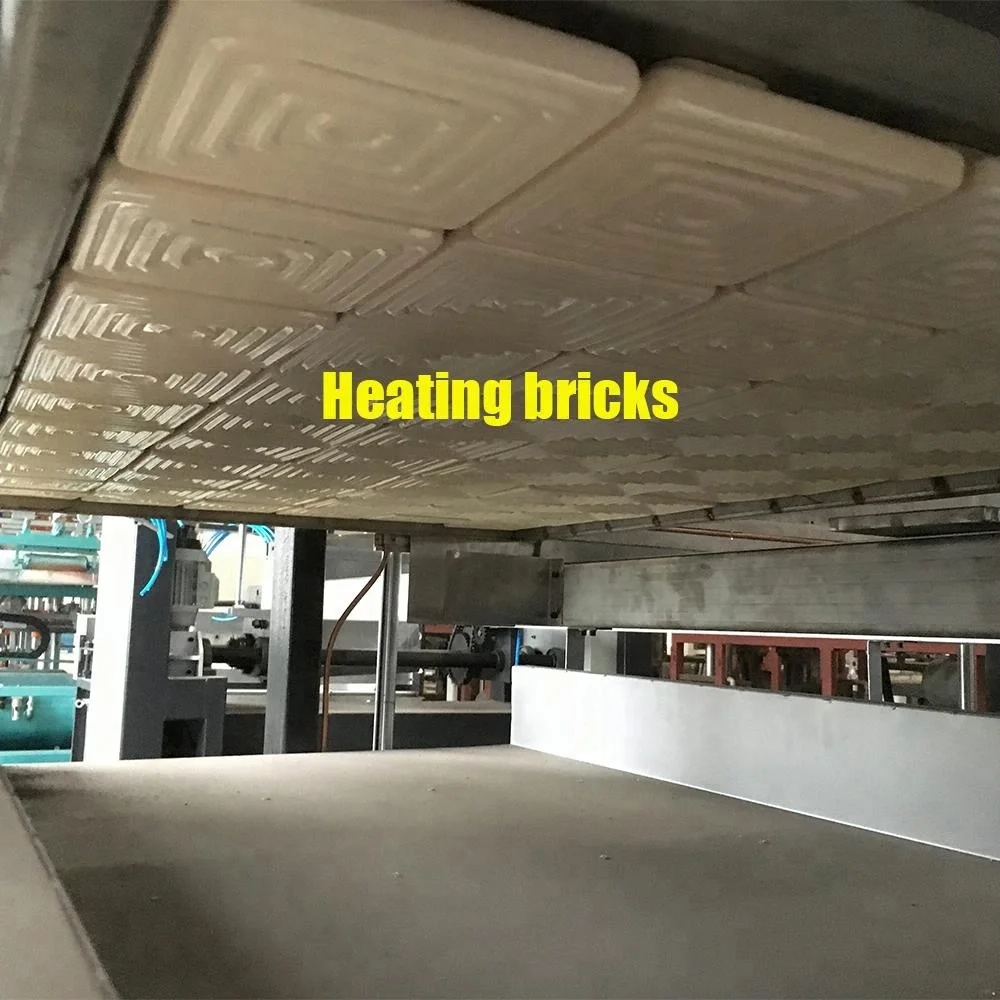

4. Heating part: using ceramic infrared heating bricks to heat uniformly, the temperature of the heat insulation plate is mirror-reflected, and the temperature control adopts a digital voltage regulator compensation thyristor temperature control system, so that the temperature of the heating area can be flexibly adjusted. The regulation can also be divided into macro-control, which is simple to operate, and has power saving and memory functions. All the controls can be operated on the touch screen, thereby shortening the heating time and increasing the production speed.

5. Electrical control system: The design adopts PLC program control, the large touch screen is used as the man-machine interface, all Chinese input is intuitive and clear, and the operation is simple. The equipment is equipped with an emergency stop switch to provide safety guarantee for production.

6. Cutting system: adopting active dual-rail horizontal cutting design, cutting products with high precision.

7. Safety protection: It adopts fully-enclosed molding device to open the door and stop the machine, and install the plexiglass protective cover at the place where the material is broken. The safety design can effectively prevent the operator from misoperation and entering dangerous institutions.

What's products this machine can do?

The plaster mold is mainly made of yellow blister gypsum powder. If the drawings are provided, the gypsum materials will be milled and manually completed according to the data and requirements of the drawings. If the actual product is provided, the outline of the mold is completed by hand-made mud first, and then vacuum-formed into a vacuum cover, and then the plaster mold is reproduced, and the mold is modified and completed. Plaster molds are easy to make. It takes about 2-4 days. The time is shorter, which is conducive to the modification of product packaging. The price is lower, but the durability is lower. After a period of use, it is easier to damage, and the produced products are more transparent. difference. It is mainly suitable for products that are not required for the first time confirmation and the transparency of the outer packaging is not high.

Our Advantages and Why Choose US;

① We are thermoforming machine factory: located in No.355 of He Peng Road, Bai He Town, Qing Pu District, Shanghai, China (201709). 30minutes away from Shanghai HongQiao Airpot(SHA)! Expressway direct to Shanghai PuDong Airport(PVG)!

② Our engineer has over 15 years experience about plastic and machines.

③ We have richful sources for raw material, molds and spare parts. Which we can provide the one stop services.

④ Professional shipping team in order to protect machines during loading.

⑤ We are also providing custom thermoforming services in case of the machine cost is out of your budget.

Our Workshop

Shipping and Delivery | ||

Machine Size | 6960*1500*2650mm | |

Weight | 3,000kg | |

Packing Details | HS Code: 8477409000 Container: 1*40HQ Each parts wrapped with stretch film or wooden crates packing(charge). | |

Contact Details: | ||||||

Contact: | Mr. Hence Hu | |||||

Mobile: | +86 18001969771 | |||||

Whatsapp/Telegram/Zalo: | 0086 18001969771 | |||||

Wechat ID: | hencehu23 | |||||

Facebook: | https://www.facebook.com/hence.hu.thermoforming.machine/ | |||||

QQ: | 375648860 | |||||

Email: | hencehu @hwblistermachine.com(Please remove the space before @ when you input the email address.) | |||||

Website: | www.hwblistermachine.com | |||||

Back to our homepage: | ||||||