Хорошая производительность кукуруза/Биомасса плотная формовочная машина/использование топлива биомасса плотный экструдер из

- Категория: Other Woodworking Machinery >>>

- Поставщик: Gongyi,UT,Machinery,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 6647.85 $* | 6979.62 $* |

| Aug-19-2025 | 6591.86 $* | 6921.78 $* |

| Jul-19-2025 | 5530.80 $* | 5807.74 $* |

| Jun-19-2025 | 6480.91 $* | 6804.57 $* |

| May-19-2025 | 5642.16 $* | 5924.70 $* |

| Apr-19-2025 | 6368.66 $* | 6686.39 $* |

| Mar-19-2025 | 6312.48 $* | 6628.5 $* |

| Feb-19-2025 | 6256.92 $* | 6569.77 $* |

| Jan-19-2025 | 6200.21 $* | 6510.85 $* |

Характеристики

Wood Sawdust Briquette Press Machine/Sawdust Briquette Machine

Process:

Material (branch or biomass waste ) → Wood Crusher → Dryer → Straw Briquette machine

Brief introduction of straw briquette machine:

straw briquette machine can convert biomass raw material and solid waste into high density biomass coal and applies for various kinds of materials which moisture content less than 30%.The machine is fully automatic with electric heating, and can adjust the humidity of materials to solve the problems of congestion and not forming.

Raw material:

1. Applicable raw material:

The raw materials of wood sawdust briquettes manufacturing machines can be wood material like sawdust, wood branches, leaves, bamboo, etc; agricultural waste such as: surgarcane, bagasse, rice husk, corn stalk, corn cob, grain stems, etc; fruit shells: peanut shell, coconut shell, coffee husk, etc.

2. Requirements of raw material:

1). The inlet size of raw material must be less than 3mm. If the raw material size are bigger, you must crush them with wood crusher firstly. The smaller the raw material, the smoothly the briquettes surface, and the better the hardness and strength.

2). The moisture of raw material for briquetting, must be less than 12%, and the moderate is 8%-12%, otherwise, the outlet briquettes are easily broken and have crevice. So before briquetting, you shall check the moisture content, if too wet, please drying them with sawdust dryer or under shunshine.

Final Product:

Technical Parameter:

Model | UTB-1000 | UTB-2000 | UTBB-2300 |

Power (kw) | 18 | 22 | 30 |

Capacity (kg/h) | 1500-2000 | 2000-2200 | 2500-2800 |

Pellet’s diameter | 6-35 | 6-35 | 6-35 mm |

Density(g/cm3) | 0.8-1.4 | 0.8-1.4 | 0.8-1.4 |

In feeding material’s Moisture condition | 10%-30% | 10%-30% | 10%-30% |

In-feeding material’s size(mm) | 5-60 | 5-60 | 5-60 |

Dimension | 2000*900*1600mm | 2000*900*1680mm | 2000*900*1760mm |

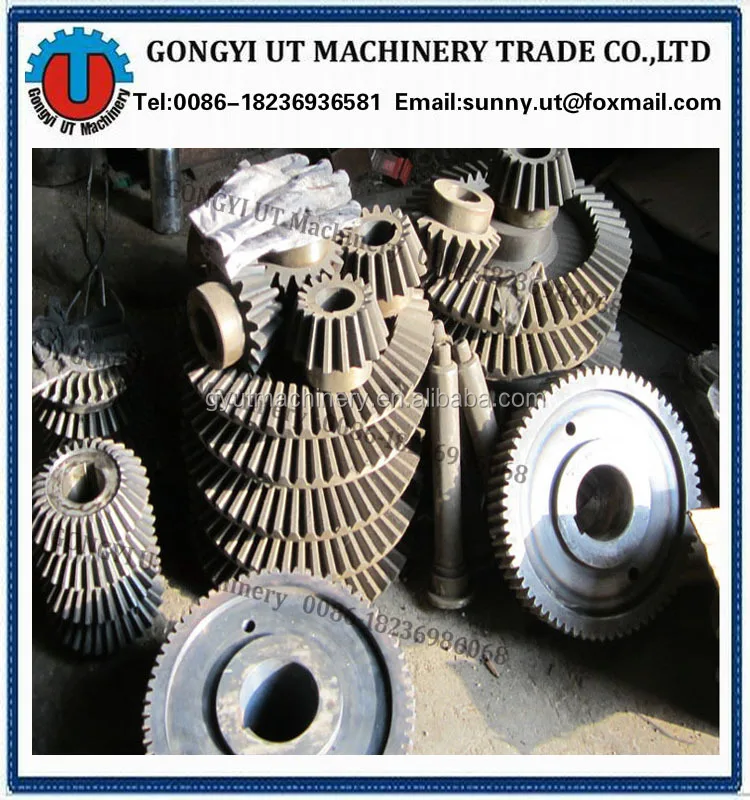

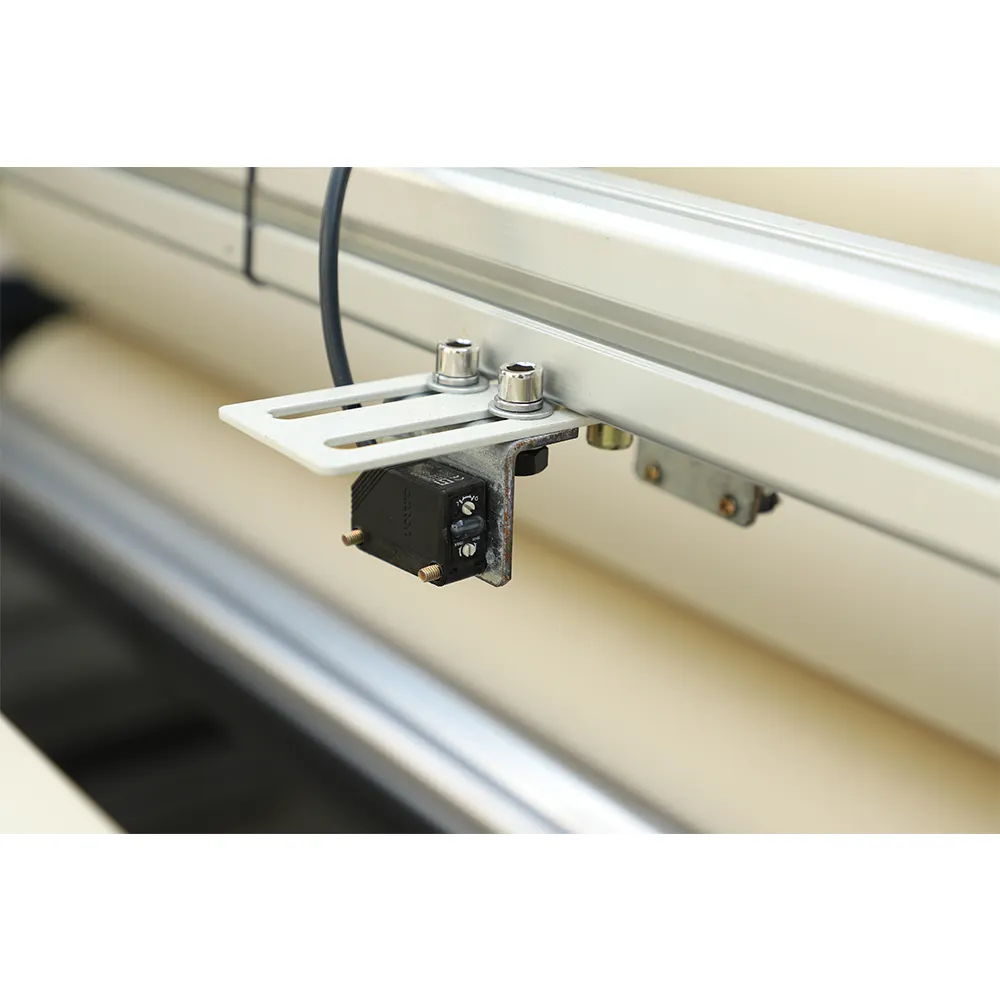

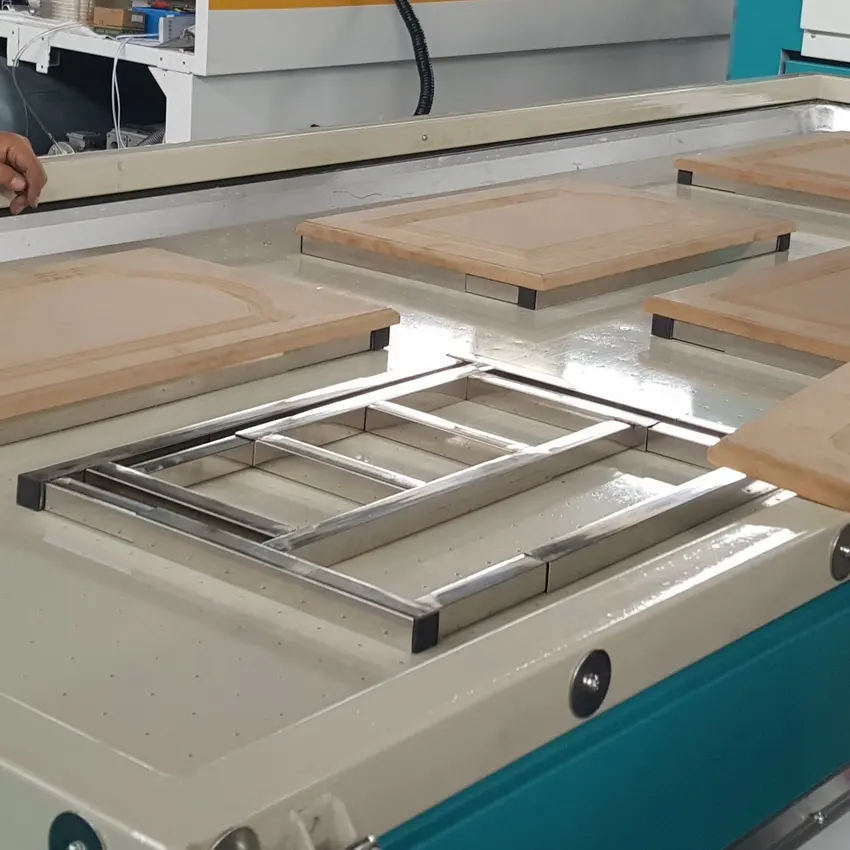

Pictures show for straw briquette machine:

1.Waterproof packing with the international export standard by 20ft, 40ft, 40hp container.

2. Equipment Fittings, Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box. Other Equipment will be packed by Color-Stripes Plastic Cloth.

3. Or as per customer's requirements.

Pre-sale:

1. Suggest to client suitable models of as customer need.

2. Introduce machine's structure and features in detail, explain the price component;

3. answer client concerned questions.

After-sale:

1. Start production as soon as receiving down payment.

2. Send photos of machine in manufacturing and finished photos to client, for your better

learn about the machine's condition.

3. Delivery machine in time, taking photos during loading, so you can "remote monitoring"

your goods.

4. Documents and certificate available in time.

5. Manual documents available. Engineer can be sent to client site for installation instruction.

1.How does the machine fit our voltage?

before shipping ,our sales will confirm with the customers about the voltage.

2.How can i buy this machine?

first talk all machine details with our sales person, then talked abt the pice, after confirming the prices.

you can choose the payment terms TT/Escrow/Western Union etc.

then you arrange deposit, after gettting the deposit, we produce the machine.

3.How can i use this machine?

we have english manual when ship the machine.

If you like this machine, pls kindly send us inquires!

Contact US: