HY-U автоматический суппозиторий машина для наполнения и

- Категория: Pharmaceutical Packaging Machines >>>

- Поставщик: Shanghai,Paikerui,Packing,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.7 $* | 0.25 $* |

| Aug-15-2025 | 0.79 $* | 0.33 $* |

| Jul-15-2025 | 0.20 $* | 0.14 $* |

| Jun-15-2025 | 0.72 $* | 0.55 $* |

| May-15-2025 | 0.86 $* | 0.29 $* |

| Apr-15-2025 | 0.0 $* | 0.56 $* |

| Mar-15-2025 | 0.69 $* | 0.56 $* |

| Feb-15-2025 | 0.16 $* | 0.18 $* |

| Jan-15-2025 | 0.31 $* | 0.34 $* |

Характеристики

HY-U Automatic suppository filling and sealing machine

Main Application:

The full-automatic suppositories production unit is a use of PLC do the whole control and use of pneumatic mode for the automatic production line source of power. This equipment combining foreign advanced technology and domestic actual situation, the design is novel, the operation is simple, is a highly efficient and stable production unit of automatic suppositories. Its leading position in domestic technical content. In the process of development, we need to consider the user everywhere, adjustable and accuracy can confirm the work, with different parameters, the equipment can mold production of different shapes and specifications of the suppositories can sue different packing material(PVC, PE, PVC/AL/PE Compound film), eliminating unqualified products etc.

Production capacity | 8000-12000 pieces/hour |

Dose per unit | 0.5-5 ml |

Deviation | ±1% |

Adapting base material | Emi-synthesis fatty acid lipo-glycerol, glycerol gelatin, carbowax |

Suppository shape | Bullet, torpedo, duck-mouth

|

Storing vessel volume | 50 L |

Air pressure | 0.6Mpa |

Water consumption | 800KG/h |

Air consumption | 1.5m3/min |

| Working voltage | 50Hz AC 380V |

| Total powder | 7.5kw |

| Machine weight | 1500kg |

| External dimension | 3470*3480*2230mm |

Machine pictures

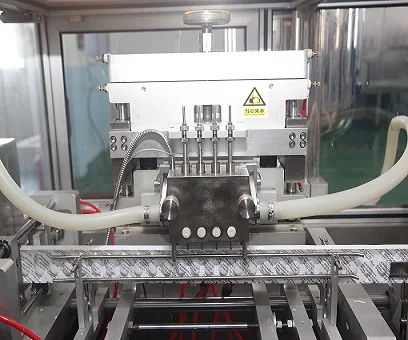

Filling part

Cooling part

Sealing part