Оборудование для холодного хранения в стойке Стальная Полка супермаркета полка вертикальная стойка роликовая формовочная

- Категория: Rolling Mill >>>

- Поставщик: Cangzhou,Zhongtuo,International,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 59500.52 $* | 62475.98 $* |

| Aug-18-2025 | 59000.31 $* | 61950.23 $* |

| Jul-18-2025 | 49500.69 $* | 51975.42 $* |

| Jun-18-2025 | 58000.65 $* | 60900.78 $* |

| May-18-2025 | 50500.8 $* | 53025.15 $* |

| Apr-18-2025 | 57000.3 $* | 59850.13 $* |

| Mar-18-2025 | 56500.15 $* | 59325.50 $* |

| Feb-18-2025 | 56000.90 $* | 58800.88 $* |

| Jan-18-2025 | 55500.31 $* | 58275.27 $* |

Характеристики

Rack Beam Cold Rolling Machine, Storage Equipment, Producing Steel Supermarket Shelves Storage Rack Roll Forming Machine

Specification:

1.low energy consuming like workforce

2.beautiful appearance;

3.High quality

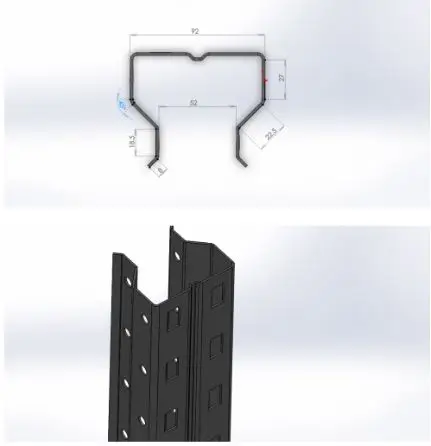

Rack beam cold rolling machine is a professional machine for making pillar in various types for supermaket. It suits for batch or mass producing supermake pillars.Here pictures of the finished products and finished products application for your reference.

As the finished products is customized and due to your requirement,here one profile drawing for your reference.

In the following part, I will show detail parameters of this machine.

Working flow of this Rack Beam Cold Storage Equipment Producing Steel Supermarket Shelves Storage Rack upright pillar Roll Forming Machine:

Decoiler-leveling-punching device-roll forming-hydraulic cutting-receiving.

The Description of whole working flow:

Description |

Introduction |

Working efficiency | 5-8m/min(not include cutting time) |

Thickness of Material | 2-3mm |

Control system | Panasonic PLC |

Uncoiler system | 5Ton Manual Operation |

Side- wheel

| 7 Sets |

Servo feeding | 1 set |

Servo feeding power: | 3.0kw |

Punching | 80T[70 times/min] |

Forming by rolling | Roll 18 times |

Roller material | GCR15 Aluminium processing after quenchin HRC58-62degree, Chrome plated |

Shaft and the diameter of axle | 45#Aluminium-processing ,diameter of axle=80mm

|

Main part power | 18.5kw |

Hydraulic motor power

| 5.5kw |

Hydraulic pressure | 12Mpa |

Scissor material | Cr12Mov, herd steel HRC 58-62 degree |

length tolerance

| 3m±1.5mm |

voltage | 380V, 50HZ,3 phase (adjustable by customer needs) |

Frame form | arch type |

Driving Method | Gear driving |

Color | Yellow and blue(adjustable) |

Size | length*Width*Height - 20*1.3*1.2m |

Package | Nude package in 2*40GP container

|

Delivery date | 60 working days |

Payment Method | 30% T/T in advance and balance 70% after inspection confirmation before shipment. |

Hydraulic decoiler with loading car:

Punching machine:

Roll forming machine:

Receiving table:

Main features of each part:

Shearing part:

(1) Shearing method:It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

(2)Material:GCR12,Quenching Oil HRC58-62°C

(3)Length :automatically cut in specified length

Counter:Panasonic

(1)Voltage:380V,50HZ,3phase(adjustable)

(2)control length automatically

(3)production counting automatically

(4)Computer controls length and quantity for finishing production in specified amount.

(5)Fix error automatically and accurately.

(6) control method:touch and button

(7)length unit:mm

Shaping machine features:

(1) Simple in construction,beautiful in appearance as it takes structural steel for welding in the whole. It is good in bearing capacity.

(2) For making sure the quality and capability of equipment, other parts of the machines were bought from well-known enterprise.

(3) It specifies length, shape, punching position, cutting position automatically and accurately, so the product is beautiful in head and end shape.

(4) Easy to install and use, it is good for factory use.

(5) low noise but high efficiency.