Полуавтоматическая машина для производства

- Категория: Оборудование для производства пластиковых изделий >>>

- Поставщик: Zhangjiagang,Keerman,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 11900.88 $* | 12495.3 $* |

| Aug-17-2025 | 11800.88 $* | 12390.0 $* |

| Jul-17-2025 | 9900.99 $* | 10395.55 $* |

| Jun-17-2025 | 11600.16 $* | 12180.30 $* |

| May-17-2025 | 10100.83 $* | 10605.99 $* |

| Apr-17-2025 | 11400.55 $* | 11970.69 $* |

| Mar-17-2025 | 11300.26 $* | 11865.46 $* |

| Feb-17-2025 | 11200.56 $* | 11760.22 $* |

| Jan-17-2025 | 11100.4 $* | 11655.61 $* |

Характеристики

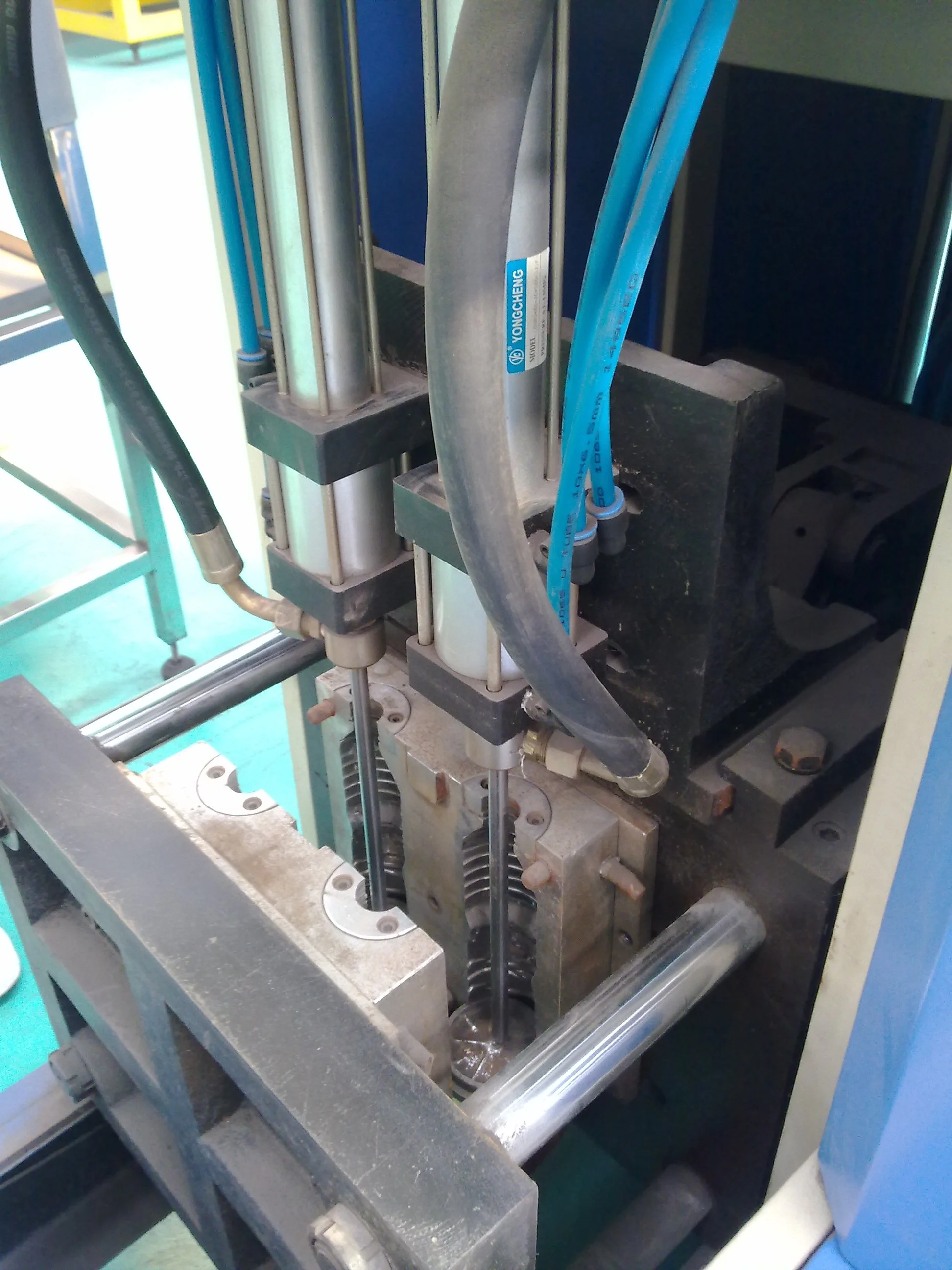

- Adopt the new double crank four-lug bar mold, with the cross to balance and fix the slide.

- Closing mould and rising bar adopt two-bar together design, favorable for the product-molding

- The advanced gas path design ,gas inlet one or two path is OK ,low pressure make the mould close-up,close mouth and rise bars

- Microcomputer control is automatic ,easy to operate

- Adjusting automatic ,easy to operate

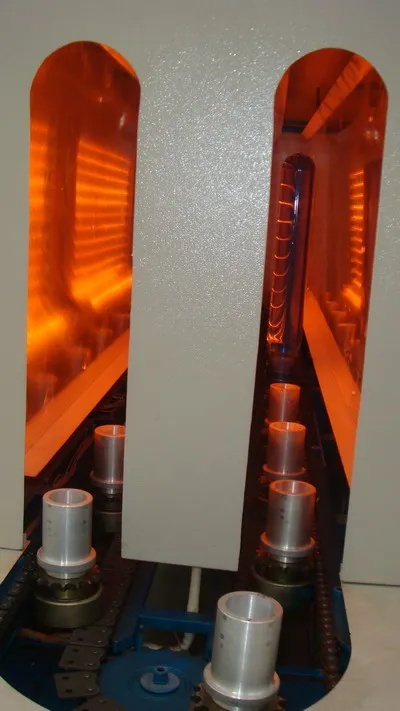

- The perform of bottle is heated by infrared, can control the constant pressure, variable frequency speed control to blow the bottle best.

Main machine (blow molding part + oven) | Model type | KM-1500 |

Product Spec | Max. product volume(L/cav) | 2 |

Max. preform neck size(mm) | 50 | |

Max. product diameter(mm) | 90 | |

Max. product height (mm) | 360 | |

Cavities | 2 | |

Blow molding part | Die force (KN) | 120 |

Die stroke (mm) | 120-210 | |

Max. mould size(mm) | 390*345 | |

Mould thickness | 120-160/220-270 | |

Mould spacing(mm) | 120-170 | |

Max. pulling stroke(mm) | 340 | |

Operation pressure(Mpa) | 0.8-1.0 | |

Operation air pressure consumption (1tr/min) | 300 | |

Blow pressure(Mpa) | 1.2-2.8 | |

Blow air pressure consumption (1tr/min) | 350 | |

Output(pcs/h) | 1500-1800 | |

Machine size(LxWxH)(m) | 1.46*0.58*1.8 | |

Package size (LxWxH) | 1.66*0.77*2.12 | |

Machine weight(KG) | 650 | |

Oven | Temperature grade(rate) | 6 |

Heating time(S) | 90-200 | |

Voltage(V) | 220 | |

Frequency(HZ) | 50 | |

Total power(KW) | 6.3-10.3 | |

Actual power consumption(KW) | ≤5 | |

Oven Size (LxWxH) | 1.35*0.55*1.15 | |

Package size (LxWxH) | 1.55*0.75*1.35 | |

Oven weight (KG) | 300 |

•Auxiliary device

Auxiliary device | Required Spec | KM-1500 |

High pressure air compressor | Operation air pressure | 3.0 Mpa |

Air displacement | 0.75 m3/min | |

Power | 9 Kw | |

R.P.M | 800 | |

Weight | 460 Kg | |

Dimension | 1.86m*0.9m*1.4m | |

Air filter (oil-water separator ) | Filter precision | ≤5ppm |

Weight | 28Kg | |

Dimension | 0.24m*0.26m*0.73m |

•Other configuration ways

Other configuration ways about the type KM-1500 | |||

Blow molding part (set) | Oven (set) | Use condition | Remark |

1 | 1 | Standard configuration | Any type |

1 | 2 | Thick preform which heating time is long |

|

2 | 1 | Thin preform which heating time is very short (normally the volume under 400ml) | Increase the air compressor displacement up to 1.2m3/min |

•Electrical parts

Electrical parts: | ||||

Item | Main control computer | Temperature gauge | Transducer | Infrared ray heating light |

Brand | Compositive minitype computer | MITSUBISHI | MITSUBISHI | KBS |

Description | Conveniency Quickly No malfunction | Easy operation Steady quality | Heating and rotating just one step | High power Long using life time, Strong penetrate |

Semi-automatic 3- 5 gallon bottle blowing machine

Semi-automatic PET bottle manufactur machine