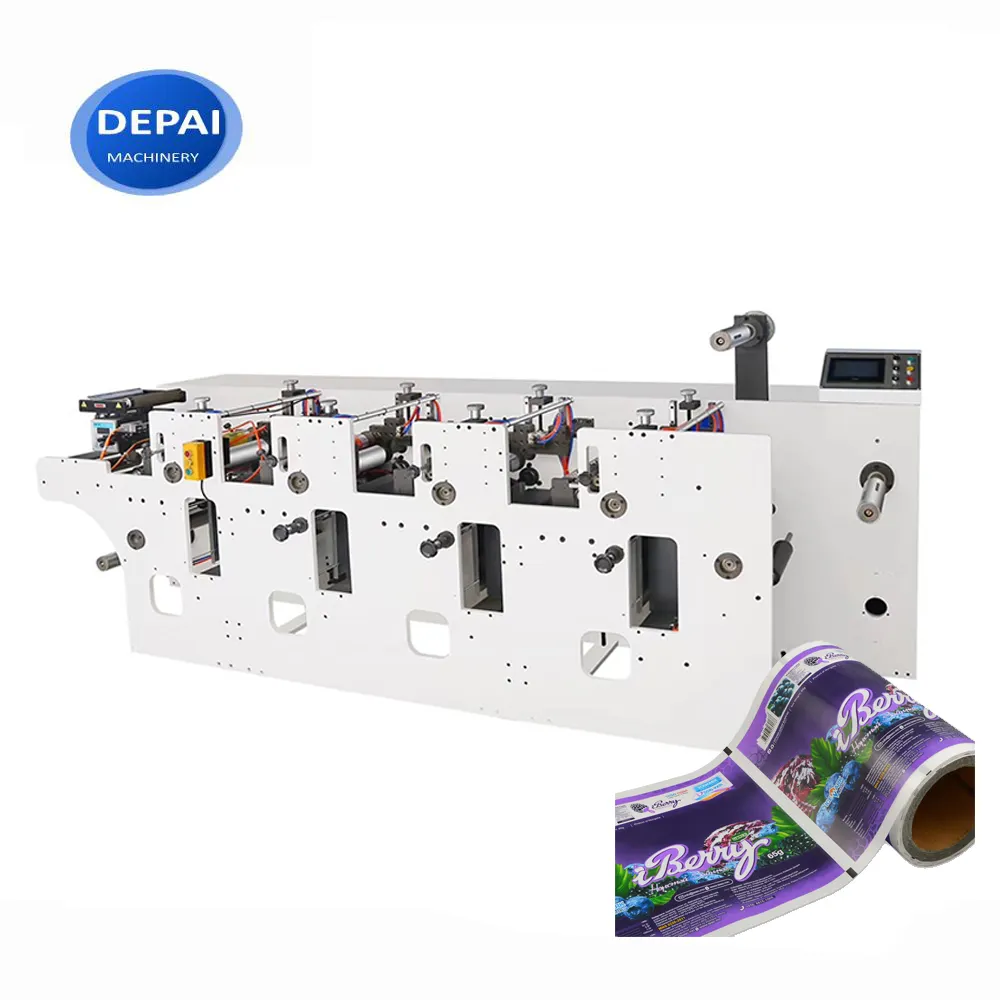

4 Цвет t-рубашка мешок BOPP пленка из полиэтилена низкой плотности флексографическая печатная машина

- Категория: Flexographic Printers >>>

- Поставщик: Wenzhou,Lisheng,Printing,&,Packaging,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 59262.44 $* | 62225.3 $* |

| Aug-16-2025 | 58764.11 $* | 61702.30 $* |

| Jul-16-2025 | 49302.31 $* | 51767.64 $* |

| Jun-16-2025 | 57768.54 $* | 60656.58 $* |

| May-16-2025 | 50298.31 $* | 52813.84 $* |

| Apr-16-2025 | 56772.52 $* | 59611.26 $* |

| Mar-16-2025 | 56274.80 $* | 59088.91 $* |

| Feb-16-2025 | 55776.41 $* | 58565.32 $* |

| Jan-16-2025 | 55278.73 $* | 58042.46 $* |

Характеристики

Product Description

This central impression (central drum)flexographic printing machine is suitable for printing such packing materials as

paper material between 20--200gsm.And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

paper material between 20--200gsm.And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

Model | YTC-4600 | YTC-4800 | YTC-41000 | YTC-41800 | |||||

Material | Non-woven fabric. Paper. Aluminum foil. Film (PVC. OPP. PE. BOPP. NY. PET. CPP)... | ||||||||

Structure type | Central impression (central drum) | ||||||||

Material Feeding Width | 600 | 800 | 1000 | ||||||

Max Printing Width | 560 | 760 | 960 | ||||||

Printing length | Standard is within 400mm, Customized is available from 300-1000mm | ||||||||

Max Printing speed | 150m/min according to different material | ||||||||

Color printing system | 4 sets, can print 1,2,3,4...colors according to CYMK | ||||||||

Register precision | Longitudinal registration≤0.1mm, Transversal registration≤0.1mm | ||||||||

Machine transmission way | Big gearwheel | ||||||||

Unwinder/rewinder paper | core 3'', 4'', 6'', can be choose | ||||||||

Drying method | Blower and heater | ||||||||

Max. oven temp. | Max. 80℃(room temp. 20℃)with temperature control system | ||||||||

Web fixing method for un/rewinder | Safety chuck+ Air expanding shaft | ||||||||

Thickness of plate (including two-sided glue paper) | Resin or rubber plate, 1.7mm, 2.54mm can be customized | ||||||||

Adhesive tape thickness for stick printing cylinder | 0.38mm or according to customer demand | ||||||||

Max.unwinder/rewinder dia. | 1000mm | ||||||||

Suitable Ink | Water based ink / Solvent ink | ||||||||

Frame thickness | 100mm | ||||||||

HS code | 844316009 | ||||||||

Main Features

1) Central impression type printing machine with better color registration. Due to the big drum, the printed material is

supported by the big drum, and greatly improving color registration, especially with extensible materials.

2) All colors printing station drived by the central drum, Less transmission errors because of less gear transmission, increase the registration precision.

3) Adopting high-quality motor, high-quality inverter, save the electricity, reduce the run fluctuation.

4) The machine is equipped with blower and heater; and the heater employed central temperature control system,

automatic temperature controller, and separated heat source.

5) The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

6) Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

7)Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance,

beating small, achieves finally perfect printing effect.

8)Accurate printing effect achieved by special gear transmission device.

9)The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

supported by the big drum, and greatly improving color registration, especially with extensible materials.

2) All colors printing station drived by the central drum, Less transmission errors because of less gear transmission, increase the registration precision.

3) Adopting high-quality motor, high-quality inverter, save the electricity, reduce the run fluctuation.

4) The machine is equipped with blower and heater; and the heater employed central temperature control system,

automatic temperature controller, and separated heat source.

5) The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

6) Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

7)Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance,

beating small, achieves finally perfect printing effect.

8)Accurate printing effect achieved by special gear transmission device.

9)The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

Sample pictures

Key configurations

RE brand web guide

Swift the

cutting function

banana bar and blade

Detailed Images

Feeding Material Part

1.Automatic stop machine when break the material. When machine stop, keep tension and avoid the material loose or line deflection.

2.Single unwinding system, equipped with air shaft , EPC and automatic tension control system with magnetic brake.

3.Auto pneumatic loading&unloading for unwind

3.Auto pneumatic loading&unloading for unwind

4.Roller core diameter: 76mm

5.Discharge maximum diameter: 1000mm

5.Discharge maximum diameter: 1000mm

Printing Sections

1.Printing consists of: central drum, plate roller, ceramic anilox roller, single doctor blade and chamber doctor blade.

2.Plate roller circumference: 300-800mm.

2.Plate roller circumference: 300-800mm.

3.Print material: resin plate or rubber plate.

4.Transmission: central drum with big gear drive the printing station.

4.Transmission: central drum with big gear drive the printing station.

5.Printing roller in&out by step motor

Drying System

1.Use hot air drying, intelligent constant temp control.

2.Drying units are installed after the printing units, and air volume can be adjusted by independent damper/panel.

3. The drying system after the printing it is about 30kw.

Rewinding Part

1.Single unwinder system, equipped with air shaft , EPC and automatic tension control system with magnetic brake.

2.Roller core diameter: 76mm

3.Discharge maximum diameter: 1000mm

4.Different material and weight have different design. (Like the picture show which is big roller friction for rewinding, special in paper rewind)

PS: Above configurations just for your reference. Know more details please connect with us! Thanks and best regards!

After Sales Service

Related Products

Certifications

Company information

FAQ

1.Are You a Factory or Trading Company?

-We are a factory, with 20 years experience on machines, our products sell very well all over the world.

2.Where is your factory located? How can I visit there?

-Our factory is located in Ruian Zhejing China. The nearest airport is Wenzhou airport. It's about 40 minutes by plane from Shanghai (5 hours by train). All our cliens, from home or abroad, are warmly welcomed to visit us.

3.What can the machine print on?

-Our machine is multifunction, can do roll to roll printing, such as paper, plastic, woven,nonwoven and so on . Surely, you can send us your products, and we'll offer you the proper machine.

4.Can I get some samples? How can I get it ?

-Yes, we can send you some free sample, but you are reponsable for delivery charages of TNT or DHL.

5.How about the after service?

-We can arrange engineers to service overseas.

6.Why choose Lisheng Machinery?

-We are one of leaders in this field(in China). Our high-quality products and service enabled us to expand our market from china to more than 60 countries.

7.I need a quotation/how much is your price?

-Please tell us your material,the width of your material,and how many color do you need? Then we will know which machine is suitable for you and suggest the right machie for you.

8.Waht's your delivery time?

-Usually finish the production within 30 days after we confirm to receive the 30% advanced payment.Actually need to check according to our stock & production plan.

-Usually finish the production within 30 days after we confirm to receive the 30% advanced payment.Actually need to check according to our stock & production plan.

9.How long is your machine's warranty period?

-All our machine have one year guarantee, starting from finished installation.

10.How would we do if the parts broken within warranty?

-We would express the free replacement partswithin the warranty date.

Похожие товары

Печатная машина для пластиковых потолочных панелей из ПВХ

US $20000-$30000

Запасные части для флексографской печатной машины

US $1000-$10000