Алюминиевые плавильные печи на масле/газе и удерживающие емкостью до 20

- Категория: Промышленные печи >>>

- Поставщик: INDOTHERM,EQUIPMENT,CORPORATION

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.62 $* | 0.81 $* |

| Aug-16-2025 | 0.46 $* | 0.14 $* |

| Jul-16-2025 | 0.88 $* | 0.53 $* |

| Jun-16-2025 | 0.66 $* | 0.25 $* |

| May-16-2025 | 0.76 $* | 0.19 $* |

| Apr-16-2025 | 0.12 $* | 0.44 $* |

| Mar-16-2025 | 0.28 $* | 0.89 $* |

| Feb-16-2025 | 0.71 $* | 0.51 $* |

| Jan-16-2025 | 0.74 $* | 0.76 $* |

Характеристики

Fuel-fired Tilting Crucible Furnaces

Fuel-fired Tilting Crucible Furnaces

T max 1200 °C and 1400 °C

Indotherm Equipment Corporation is one of the repeated manufacturer, exporters of furnaces for melting of non-ferrous metals from India. As per the customer’s needs, we offer stationary and tilting crucible furnaces.

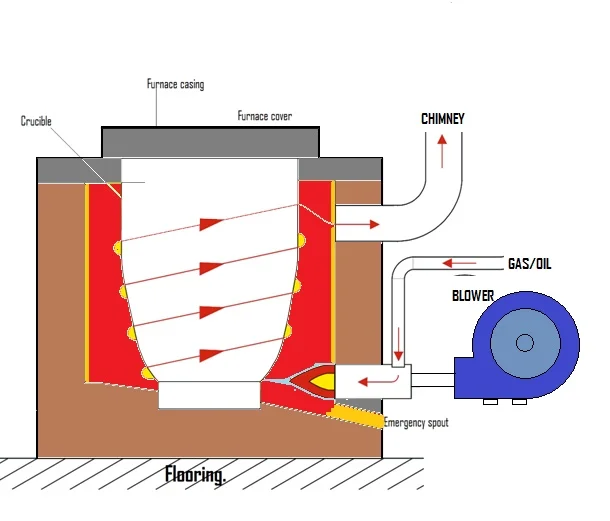

Tilting Crucible melting furnaces are one of the known as well as unique design melting unit used in the foundry. The furnace is fitted with a crucible inside which is either of Graphite or Silicon carbide material which contains the metal Scrap. The scrap is heated via transmission of heat through the walls of the crucible by a fuel fired burner. The heating fuel is typically coke, oil, gas or electricity. Tilting Crucible melting is commonly used where small batches of low melting point alloy are required. Resources expense of these furnaces makes them attractive to small non-ferrous foundries.

Tilting Crucible Melting furnaces are typically classified according to the method of removing the metal from the crucible:

Model | Capacity | Melting rate* | Melting rate* | Burner | T max | Outside dimensions | Weight | ||||

180 TF | 180 | 550 | 220 | - | 300 | 1200 | 2900 | 2100 | 1600 | 1350 | 1800 |

330 TF | 330 | 970 | 240 | - | 300 | 1200 | 3000 | 2200 | 1700 | 1530 | 2200 |

370 TF | 370 | 1200 | 260 | - | 300 | 1200 | 3000 | 2200 | 1700 | 1630 | 2400 |

570 TF | 570 | - | 400 | - | 390 | 1200 | 3200 | 2400 | 2100 | 1670 | 2600 |

750 TF | 750 | - | 420 | - | 450 | 1200 | 3300 | 2500 | 2250 | 1770 | 2900 |

1 Ton | 1000 | - | 450 | - | 450 | 1200 | 3300 | 2500 | 2250 | 1950 | 3300 |

400 TF | 120 | 400 | - | 330 | 400 | 1400 | 2800 | 2000 | 1600 | 1400 | 2300 |

500 TF | 150 | 500 | - | 360 | 400 | 1400 | 2800 | 2000 | 1600 | 1400 | 2500 |

600 TF | 180 | 600 | - | 380 | 400 | 1400 | 2900 | 2100 | 1600 | 1400 | 2700 |

Thin Film Plastic Wrap

along with Wooden Pellet Boxes.

Established in the 1990 Indotherm Equipment Corporation is an ISO 9001-2008 certified export oriented manufacturer of furnace

INDOTHERM EQUIPMENT CORPORATION is a 25 year old corporation that is concerned in giving finest possible services to its clientele, cost-effectively, by means of towering quality group as its workforce. We are based in INDIA where the personnel are extremely low down prices. Over the time we have grown into an extensive business unit with its heart potency in furnaces manufacturing for a variety of uses like Steel rolling mills, solution annealing, Aluminum industry etc. We also embark on turnkey projects for Steel rolling mills and Aluminum wire rod projects. Our services include supply of complete machinery and skilled workforce from INDIA at competitive prices.

We are Industrial Furnaces manufacturers, Industrial Furnaces suppliers, Industrial Furnaces producers, Industrial Furnaces exporters, Industrial Furnaces equipment manufacturer.

Indotherm equipment Corporation is in the Directory of furnace manufacturers, furnace exporters as well as furnace suppliers. You can get details of manufacturers & exporters of furnace, electric induction furnace from any reliable refractory supplier.

- Reply your inquiry in 24 working hours.

- Experienced staffs answer all your questions in fluent English.

- Customized design is available. UEM&UBM are welcomed.

- Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

- Special discount and protection of sales are provided to our distributor.

- Professional factory : We are manufacturer, specializing in producing all kinds of machinery for more than 20 years, competitive with good quantity.

- Sample: We can send out sample for test in one week if the order quantity is big enough. But the shipment charges is usually paid by your side, the charges will be rebounded when we have formal order.

- As an honest seller, we always use superior raw material, advanced machines, skilled technicians to ensure our products to be finished in high quality and stable feature. Welcome to contact us or visit our company.

What is the power supply of the furnace?

The power supply of the furnace is to be decided by the customer's side. We are able to adjust the power supply (volt, and phase) through a transformer so that the furnace is ready for use at the end user's site.

What information should the customer provide to get an accurate quotation from us?

The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc.

What is the payment term?

The payment term is 30% down payment, and 70% before delivery (T/T mode).

What is the delivery time?

The delivery time of the furnace is 10-20 days after receipt of down payment.

What is the warrantee period of the furnace?

The warrantee period is 1 year after completion of test-running.