Установка по переработке автомобильного аккумулятора с переработкой свинца под ключ высокой технологией делает индотерм доступным на 10 тонн

- Категория: Промышленные печи >>>

- Поставщик: INDOTHERM,EQUIPMENT,CORPORATION

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 95200.65 $* | 99960.38 $* |

| Aug-19-2025 | 94400.63 $* | 99120.91 $* |

| Jul-19-2025 | 79200.29 $* | 83160.63 $* |

| Jun-19-2025 | 92800.45 $* | 97440.3 $* |

| May-19-2025 | 80800.95 $* | 84840.97 $* |

| Apr-19-2025 | 91200.78 $* | 95760.36 $* |

| Mar-19-2025 | 90400.99 $* | 94920.62 $* |

| Feb-19-2025 | 89600.86 $* | 94080.58 $* |

| Jan-19-2025 | 88800.80 $* | 93240.34 $* |

Характеристики

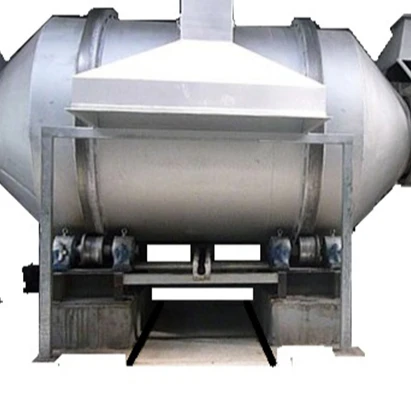

Indotherm Rotary Furnace for Recovery of Lead from Used Acid Batteries

We design and fabricate High-Temperature Oil Fired and Gas Fired Rotary Furnace for processing and smelting of lead from sources such as Used Batteries, Lead Waste material, Oxides recovered from BBSU, Dross, Sinter Ore, and other multiple sources. Our fabricated rotary furnace has the versatility to reach an optimum temperature up to 1250 Deg. C.

Rotary Furnace is connected with exhaust refractory lined damper which carries the hot flue gases to settling temperature. The Settling chamber settles the gases and with the decrease in temperature, it moves on to the cooling line making its way to the baghouse which filters the oxide and gases so the same can be sent to the chimney for outlet emissions.

Fugitive Emissions and Control System

As explained above the flue gases go through a series of equipment which gets treated on every stage and parameter testing so the treated gases can be released back as per the permission able limits stated by pollution norms of the county.

Smelting and Recovery

Indotherm Rotary Furnace is fabricated from mild steel 16 mm plate and the same is placed on the structural channel base with a rotating mechanism. We use heavy thermal conductivity refractory which can sustain high temperature up to 1400 Deg. C The material of the furnace can be placed manually or via the help of a furnace charge.

Combustion Systems:

We use self-proportionating and modulating burners which makes the furnace more efficient and economical in use. We believe that good combustion systems are the life and soul of the furnace, the burner can be automatic as well as manual according to customer use.

When compared to the traditional way of melting and recovering lead from Blast furnace Indotherm Rotary Furnace for Melting and Recovery of Lead has the following advantages:

- Treatment of Metal is Easy, Safe, Reliable, and Economical.

- Production is faster and continuous

- The furnace is high temperature so all kinds of waste can be processed furnace as Dross, sinter, Lead Sulphates, Lead Concentrates, Oxide, Ore.

- Recovery of Metal is Higher

S. No. | Particulars | Details |

01 | Production Capacity | 03 MT per Batch to 20 MT |

02 | Fuel Type | Used Oil, Furnace Oil, Natural Gas |

03 | Raw Materials | Lead plates from Batteries, Soda Ash, Mill Scale and Charcoal |

04 | Automation | Furnace charger + Automatic Burners |

05 | Fuel Consumption | Will depend of Fuel and Capacity of Furnace |

06 | Air Pollution Control System | Will be Calculated as per the fuel used and capacity of furnace. |

Man Power | ||

07 | Supervisor | 01 |

08 | Skilled Labour | 03 |

USED ACID BATTERY LEAD RECYCLING PLANT | |

| Fuel Consumption | 1000KWH/ton at 1200 Deg. C Tap out the temperature |

| Recovery Rate | 64% - 67% depending upon the type of scrap |

| Capacity | 3 MT /Batch to 20000 MT/Batch |

| Loading | Through Auto charger ( Optional ) |

| Metal Tapping | By Plug system |

| Fuel | LDO/FO/HSD/LPG/Propane |

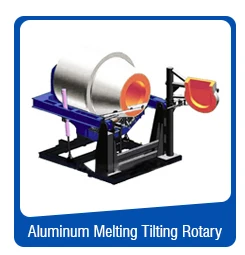

In the year 1991, Indotherm Equipment Corporation started its operation with a vision of manufacturing, exporting, and supplying of high standard Furnace and Belt Conveyor. Being an ISO 9001:2008 certified firm the range of products which we have been delivering to our comprise Hydraulic Tilting Furnace, Reverberatory Furnace and Tilting Reverberatory Furnace. We started our operation with an aim to deliver a product which is safe and environment friendly as well. Our range of products saves energy and consumes less fuel which is one of the major features of our product.

We have a directory of authorized vendors and after having an aggressive research, we select the most reliable vendor. The raw materials which are supplied to us are quality checked at their end, we after acquiring it from them also conducts a quality test and thus make sure that it meets the industry parameters. Since we started, we have been highly appraised by the clients for delivering them an excellent product. In these years of operation, we have been able to create a position in the market by offering excellent quality of service and products. We also have an excellent packaging unit equipped with latest machinery which helps in packing the products, making sure that they are safe while being exported and supplied. We also have an efficient team who keep themselves up breast with the technology and accordingly put their efforts in delivering high-class products. We export our products across the globe.

Mr. C. L. Tripathi has always followed a customer centric approach and maintained a friendly business policy. His vision and mission has always been in delivering a superior product which is safe for the environment and also consumes less energy. It is his guidance that we have been able in bringing our client a quality product.

Our Excellence :

Our knowledge has been functioning for over 20 years with flourishing in the universal Aluminium industry, where we are well thought-out as a spot supplier for the chief and derivative industries as well as for the aluminum foundry industry. Our ground-breaking modern colossal equipments and plan solutions that protect profitability merit goes to better energy efficiency, reduced upholding downtime, and longer repair cycles.

Our worldwide presence and local experience allows us to offer the most suitable and cost effective technical solutions that will contribute to our customers' productivity and efficiency. In the aluminium industry, we focus our efforts on the following concerns:

- Ensure the safety, reliability, and productivity of the equipment

- Suppress corundum build-up

- Withstand mechanical abuse

- Products & Applications

- Installation, Commissioning and Turnkey Maintenance

Turnkey New Projects