10 тонн машина для обработки пальмового масла линия очистки в

- Категория: Oil Pressers >>>

- Поставщик: Zhengzhou,Qi'e,Grain,And,Oil,Machinery,Co.,Ltd.Zhengzhou,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 2516334.43 $* | 2642151.67 $* |

| Aug-18-2025 | 2495188.79 $* | 2619947.56 $* |

| Jul-18-2025 | 2093420.78 $* | 2198091.23 $* |

| Jun-18-2025 | 2452897.14 $* | 2575542.11 $* |

| May-18-2025 | 2135712.83 $* | 2242498.32 $* |

| Apr-18-2025 | 2410605.58 $* | 2531135.11 $* |

| Mar-18-2025 | 2389460.30 $* | 2508933.34 $* |

| Feb-18-2025 | 2368314.75 $* | 2486730.22 $* |

| Jan-18-2025 | 2347168.33 $* | 2464526.50 $* |

Характеристики

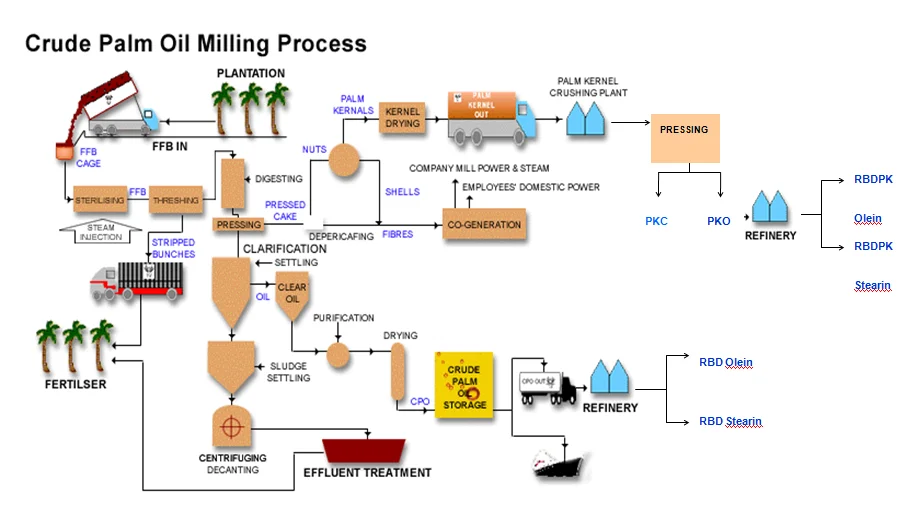

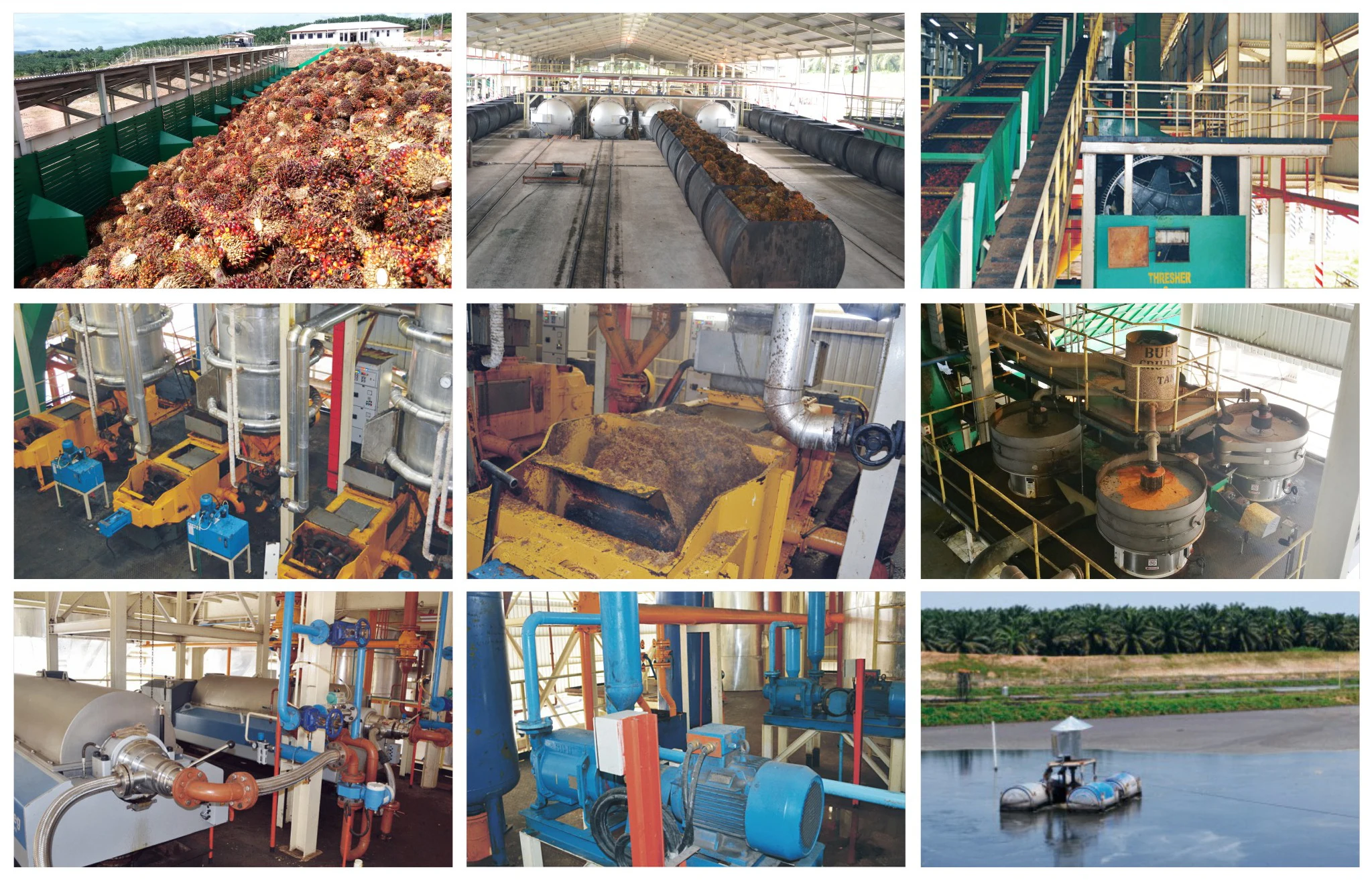

It mainly include following stations of 10tons palm oil production processing machine palm oil refinery line in Malaysia:

Reception Station - Steriliser Station - Threshing Station - Pressing Station - Clarification Station - Depericarping Station - Kernel Recovery Station - Boiler House.

Reception station

Used for loading palm fruit brunch from plantation,transport to sterilizer,Reception station adopt steel structure and concrete

structure.Save equipment cost and construction cost. Have hydraulic control system,hydraulic door open/off automatic achieve

continuous operation.Reduce operator,operate more easily and improve work efficiency.

Sterilization station

The sterilizer works with direct steam, the steam can weaken the activity of the enzyme, prevent it getting rancid, ensure the

good quality of the crude oil. At the same time, it is good for the following treshing processing. We have designed both

horizontal and vertical sterilizer, for larger and smaller line.

Threshing station

The rotating of the drum in the tresher can separate the fruit from the bunch. The fruit will be conveyed to the digester through

elevator, and the empty bunch will be conveyed to the outside part through scraper conveyor. The spindle adopts once forging

technology, which can make the equipment more solider and durable. At the same time, we have already designed the non spindle

tresher, which is driven by the link chain. It can save the producing cost in a large scale.

Digesting station

The digester is used to adjust the moisture and temperature of the fruit,finally it can increase the oil extraction rate. The

digester adopts liquid level control system, which can distribute the material all by itself. To realize the automatic working.

The presser adopts hydraulic control system to adjust the distance of different pressing worms, it is applicable to different

kinds of palm fruits, and it can ensure the high oil extraction rate.

Pressing machine

The palm fruit oil yield increase by adjusting material moisture and temperature in digesting tank.digesting tank uses liquid

level control, so material can distribute automatically and equipment runs fully automatically. Pressing machine uses hydraulic

control system to adjust spacing between pressing bolts. So it can be suitable for various palm fruit species and guarantee the

oil yield.

Clarification station

Using the latest technology, under the condition of ensuring the good quality of the oil, reduce the equipment cost as much as

possible, reduce the loss of the oil, in the practical producing ,the new technology can make the loss of oil less than 1.3%.

Any special requirement of shipping, please talk with us, we will help you to solve the problems.

if the amount of goods to be deliverd is relatitively small ,the goods will be packaged in the form of export wooden boxes .if the goods are shipped in the large quantities,the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Pre-sale services

2) Designing and fabricating the products in accordance with the special requirements of the clients;

3) Training technical personnel for our clients;

4) Providing construction and technology consultations or working out proper construction schemes for those new, special ordifficult projects.

After-sale services

1) Assisting the clients preparing for the first construction scheme;

2) Installing and testing the equipment;

3) Training the first-line operators on site;

4)Supplying spare parts with cost.

The production and comprehensive economic indicators lie in forefront of the same industry, with products selling all over the county and exporting to over 40 countires, such as Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Korea, Vietnamese, Pakistan, Romania, and Serbia, etc.

10-500T/H oil material first cleaning, drying and storage section turnkey project. | 30-1000T/D oil continuous grade one or two physical (chemical) refining production line. |

20-3000T/D sunflower oil, rice bran oil, corn germ oil dewaxing turnkey project. | 10-200T/D Fatty acid esterification production cooking oil production line. |

1tph-120tph Palm Fruit Processing Line and Palm Kernel Processing Line. | 250TDPshea nut pressing,100TDP oil refining and oil fractionation Nigeria equipment. |

300TPD soybean pre-treatment and solvent extraction plant and oil refinery egypt plant. | 50TDPpalm oil refinery and fractionation plant and oil filling machine ghana. |

300TDP cotton seed pretreatment,solvent extraction and oil refining equipment kazakhstan. | Two sets 50TPD oil refining production line pakistan. |

Q:Are you a manufacturer or a foreign trade company?

A:We are a manufacturer in China built in 1982.

Q:What if I could not operate this product?

A:Our machine operation video and manual are for your reference. If necessary, we will send engineers to train for you personally.

Q:Can you provide more information about production and quote the best price?

A:Of course, but first we have to confirm your needs. According to your needs, we will choose the right product for your reference. When we determine one or several products, we will quote you the best price.

Q:How to place an order?

A:First send us the enquiry below, including the device name, daily production, work hours, main processing materials, etc., then our sales manager will send you the information for your reference.

Q:How long does it take to receive my product?

A:It is not yet possible to determine the time because the shipping distance and production cycle are uncertain.our business manager will recommend the appropriate transportation route for you to ensure safe and fast delivery of the goods.

Q:How is the quality of your products guaranteed?

A:After the completion of production, our quality inspection can not test the product. If you need it, we can provide third-party testing service to ensure the stable production of the equipment.