Портативный сварочный аппарат из ПТФЭ ручной

- Категория: Plastic Welders >>>

- Поставщик: Ningbo,Davison,Machinery,Manufacture,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 357.40 $* | 375.49 $* |

| Aug-20-2025 | 354.60 $* | 372.77 $* |

| Jul-20-2025 | 297.50 $* | 312.92 $* |

| Jun-20-2025 | 348.78 $* | 365.6 $* |

| May-20-2025 | 303.11 $* | 318.9 $* |

| Apr-20-2025 | 342.32 $* | 359.86 $* |

| Mar-20-2025 | 339.77 $* | 356.64 $* |

| Feb-20-2025 | 336.83 $* | 353.72 $* |

| Jan-20-2025 | 333.91 $* | 350.71 $* |

Характеристики

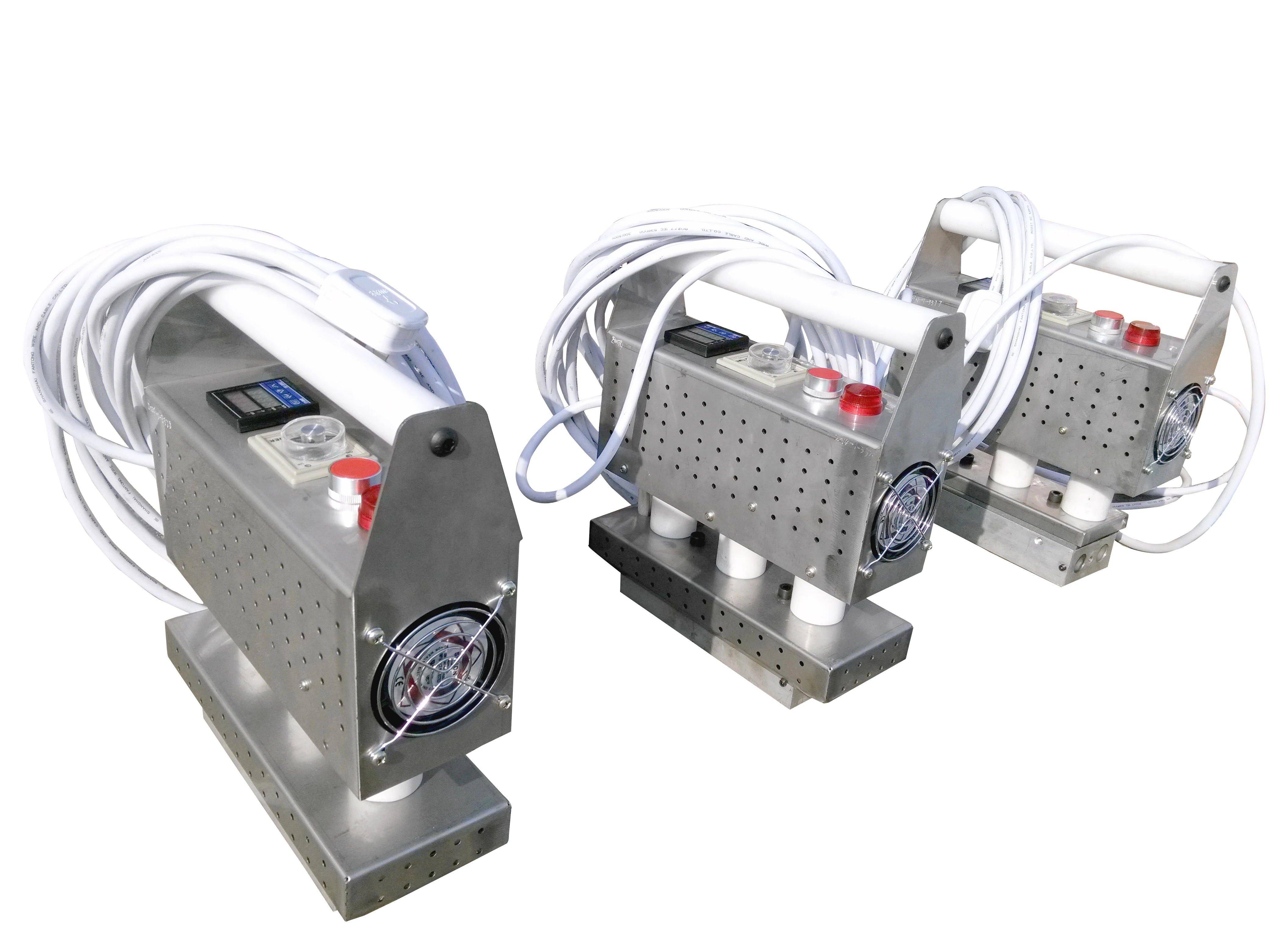

Plastic handle welding machine

Working principle:

Put the PTFE film between two welding horns, when the PTFE film welding machine is working, the temperature of two welding horns reach 450-500°C,let the high temperature adhesive tape material(between two PTFE film)reach the melting point,so achieve welding effect.

Applications:

1. The operation is simple, can grasp the operating process quickly.

2. The machine volume small, save space.

3. The machine weight is small, easy to locate.

4. According to the material, the temperature can be set freely.

5. The machine is equipped with timer alarm, temperature controller, facilitate welding material.

Models & Specifications:

Machine name | Hand welding machine |

Model | DXHW220 |

Voltage | 220V 60Hz |

Power | 1000w |

Temperature range | Form room temperature to 500 ° C |

Single welding area | 200x60mm |

Mode of operation | Manual operation |

N.W. | 10 kgs |

Dimension | 270x100x330mm |

Pictures:

1set/wooden box;

1500x1000x700mm

300/250KGS

1. Whichtype of material is suitable for this high frequency welding?

A. PVC,PU or PVC coated fabric material

2. What’s the different between High Frequency Plastic welding and Heat Sealing?

A. These two method might seem very similar, however, two very different principle are applied. High frequency plastic welding machine apply high frequency signals onto the PVC material, making the Molecule of the friction material oscillate rapidly thus create internal heating, and material temperature rises and bound together. The heat welding is using normal hot electric heating device consists of an external heating on products, such as heating of PE materials.

3. What cause the spark during high frequency welding?

A. The most common cause of sparkle is the dirt. Clean space is required for high frequency welding, especially around electrode. The applied product also must not contain dirt or the sparkle will be very likely to accrue.

4. How to choose the suitable high frequency output power for your product?

A. Commonly speaking, 1KW of high frequency output can weld 12 cm2 of welding area. You can approximate the output power you need according to your product’s welding area.

5. What type of pen or pencil can I use to mark on welding product?

A. Please do not use pencil or marker. Anything that contain carbon will cause the spark.

6. How to adjust the output power.

A. The size of die has a direct relation with the output power. Dies of different sizes lead to different strength of current. In general, large-size molds need a larger current.