Пиролиза отходов шин завод по переработке изношенных автошин производитель в

- Категория: Управление отходами >>>

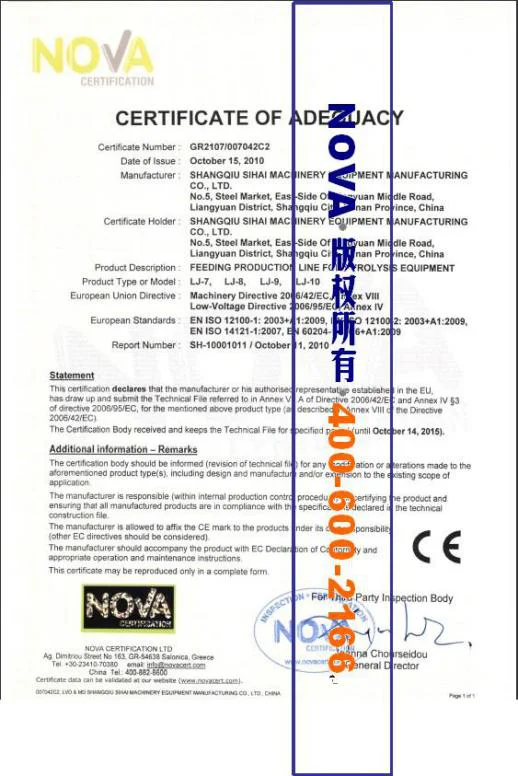

- Поставщик: Shangqiu,Sihai,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 52122.92 $* | 54728.72 $* |

| Aug-15-2025 | 51684.7 $* | 54268.3 $* |

| Jul-15-2025 | 43362.57 $* | 45530.22 $* |

| Jun-15-2025 | 50808.30 $* | 53348.84 $* |

| May-15-2025 | 44238.16 $* | 46450.18 $* |

| Apr-15-2025 | 49932.37 $* | 52429.11 $* |

| Mar-15-2025 | 49494.3 $* | 51969.34 $* |

| Feb-15-2025 | 49056.39 $* | 51509.43 $* |

| Jan-15-2025 | 48618.51 $* | 51049.95 $* |

Характеристики

waste tyre recycling plant manufacturer in india

Shangqiu Sihai Machinery Equipment Co., Ltd. is a collection of research and development, production, sales and after-sales services, which has rich experience in the field of waste management over 20 years.

Our company covers an area of 37,000 square meters. Our company has a huge professional technical team, including 2 senior engineers, 16 senior technicians, 28 mid-class technicians, and 82 technicians.

Our main products are divided into two catalogries: pyrolysis plant and distillation machine, including tires

pyrolysis plant, tyre pyrolysis plant, waste rubber pyrolysis equipment, waste plastic recycling machine

and other waste management machines, and waste oil distillation equipment, waste engine/motor oil recycling machine, tire oil distillation plant, plastic oil refinery machine and crude oil distillation equipment.

Our products have been exported to China, South Korea, Thailand, the Philippines, India, Malaysia, Malaysia, Myanmar, Afghanistan and the United States and other countries and regions, which obtain a better reputationand happy feedback.

We will continue to innovate and improve to give you a nice turnkey projects.

Founction:

pyrolysis plant can recycle the waste tyre /rubber/plastic into Diesel oil with high valued.

1.Raw Meterial can be used for pyrolysis plant:

A. The materials consists of plastic and rubber such as rubber, waste tyres, and waste rubber soles and so on. The oil production of the tyres beyond dia650mm is around 45%;The oil production of the tyres of the bikes, motorcycles and cars is 35%; The oil production of rubber soles is around 27-33%; The oil production of black rubber is about 35%; The oil production of gum outsole is around 45%.

B.Plastics: Since there exists great differences between the waste plastics, so the oil production also differs a lot. Generally speaking, it is between 35-85%.

2.The opptional fuel can be choosed for pyrolysis plant running

1. Wood

2. Fuel oil (including the production made )

3.Coal, charcoal

4.Nutural gas(including the waste gas produced from process)

5.The carbon black produced from process

3.Products parameters by pyrolysis plant process:

1.The fuel oil extracted from the waste plastics: Density: 0.80±0.02,dark red color, fuel value is 8500kcal.

2. The fuel oil extracted from the waste rubber: Density: 0.90±0.02,black color, fuel value is 10500-10100kcal.

4.The main parts list in pyrolysis plant:

Item | Description | Specification | Quantity | Remark |

1 | Reactor | 2.2M*6.6M | 1set | Q245R Boiler plate 16mm |

2 | Shell furnace base | 3.0M*5.4M | 8pcs |

|

3 | Condensor | 600*2500 6mm | 3sets | 48pcs tube pipe inside |

4 | Draft fan | 5.5kw | 1set | 380v |

5 | Moto reducer | 5.5KW | 1set | 380v |

6 | Oil gas separator | 900*1800 | 1set | 10mm board |

7 | Cooling tower |

|

| 100tons |

8 | Water sealing | 900*1500 | 2sets | 10mm board |

9 | Desulfurization and dusting system | 900*2800 | 1set | 6mm board |

10 | Chimney | 280 | 1set | 18m |

11 | Air blower | 250W | 4set | 220v |

12 | Gas burned spay |

| 4sets |

|

13 | Exausted gas reclycling pipe |

| 7roots |

|

14 | Water pump | 1.5kw,3.0kw | 2set |

|

15 | Heavy oil tank | 800*1800 | 1sets |

|

16 | Product oil tank | 1,400*3000 | 2set |

|

17 | Temperature gauge | 0-500°C | 5pcs |

|

18 | pressure gauge | Y100-0.16 | 3pcs |

|

19 | Safety system | Alarm system Valve emptying | 3sets |

|

20 | Electricity central control plate |

| 1set |

|

21 | Reactor cool down and safety system |

| 1set |

|

Our competitive points in pyrolysis plant parts

1.outside gear support for reactor which can ensure the reactor was stable during it was running

2.more than two discharge system which short the discharge time 0.5 hours at least

3.steam boiler system which can doow down the reactor within 2hours .

4.extral steam feeding system after finish the whole produce which remove the burn gas in the

reactor to avoid any fire injurt .it give all of the new user 100% safety .

5.spares parts for one year running freely

6.the perfect carbon black discharge system which can make the our work aera was clean

Our competitive points in Distillation parts