Подержанные машины для восстановления протектора шин/шлифовальные и полировальные машины/Оборудование шин

- Категория: Tire Retread Machines >>>

- Поставщик: Qingdao,Crowns,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-15-2025 | 6128.89 $* | 6251.34 $* |

| Jul-15-2025 | 4970.38 $* | 5069.10 $* |

| Jun-15-2025 | 6031.66 $* | 6152.57 $* |

| May-15-2025 | 5983.47 $* | 6103.17 $* |

| Apr-15-2025 | 4777.62 $* | 4873.50 $* |

| Mar-15-2025 | 5887.86 $* | 6005.40 $* |

| Feb-15-2025 | 5838.90 $* | 5955.6 $* |

| Jan-15-2025 | 5790.62 $* | 5906.35 $* |

Характеристики

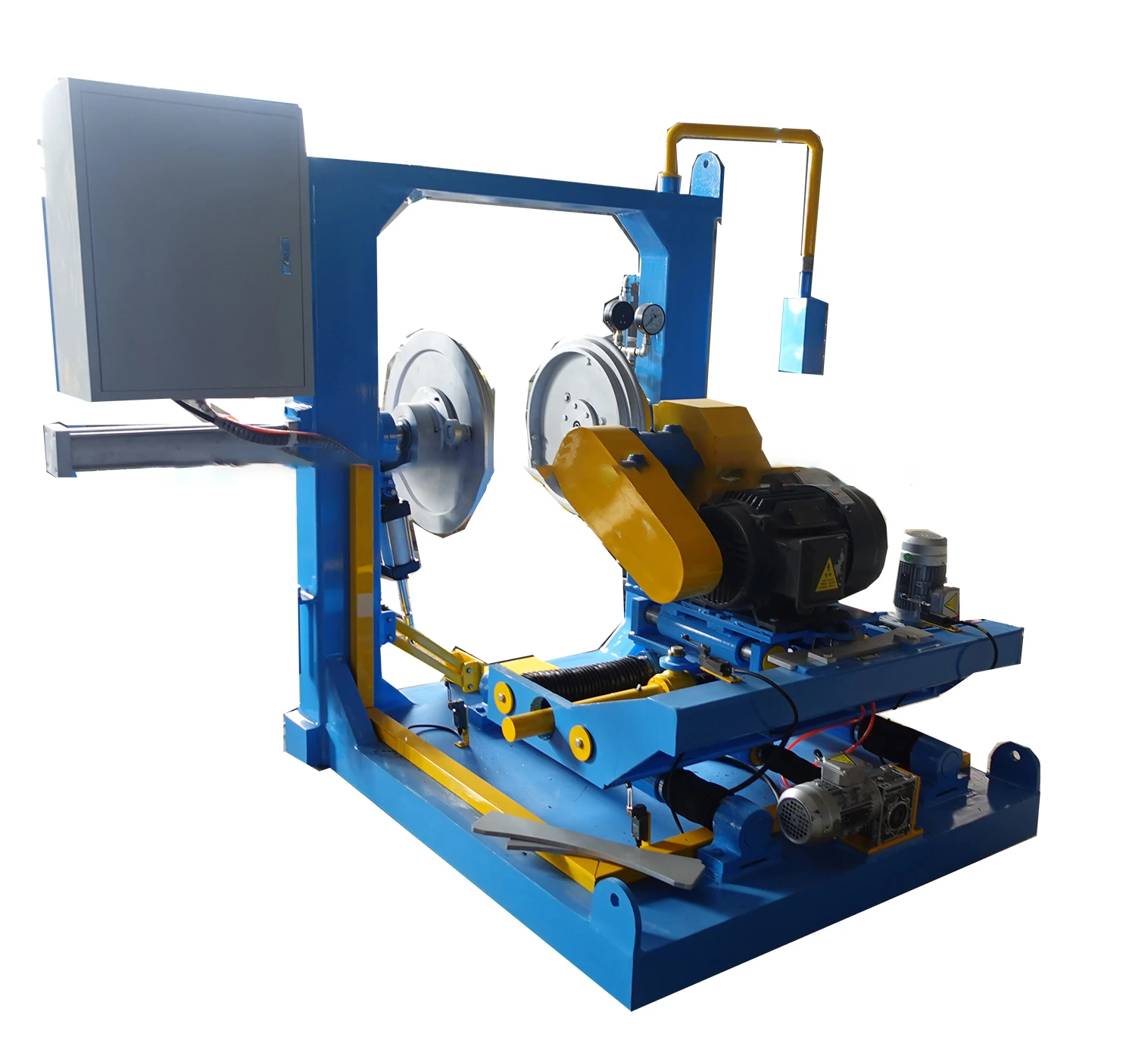

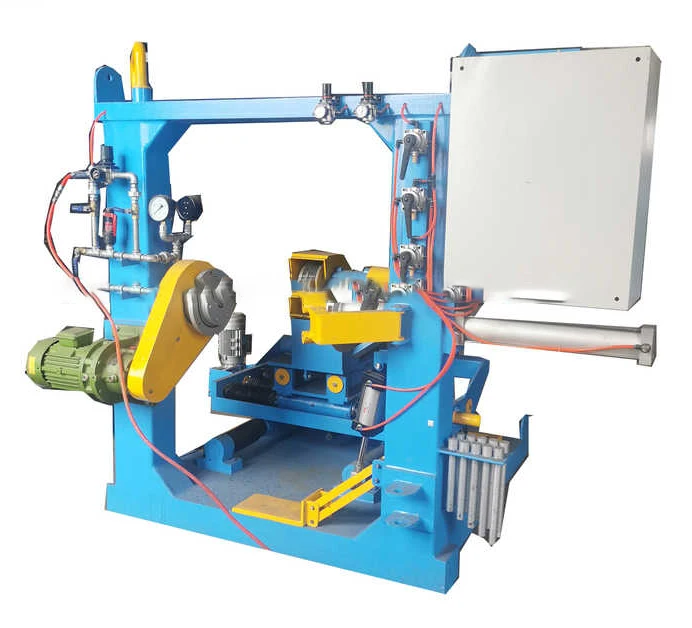

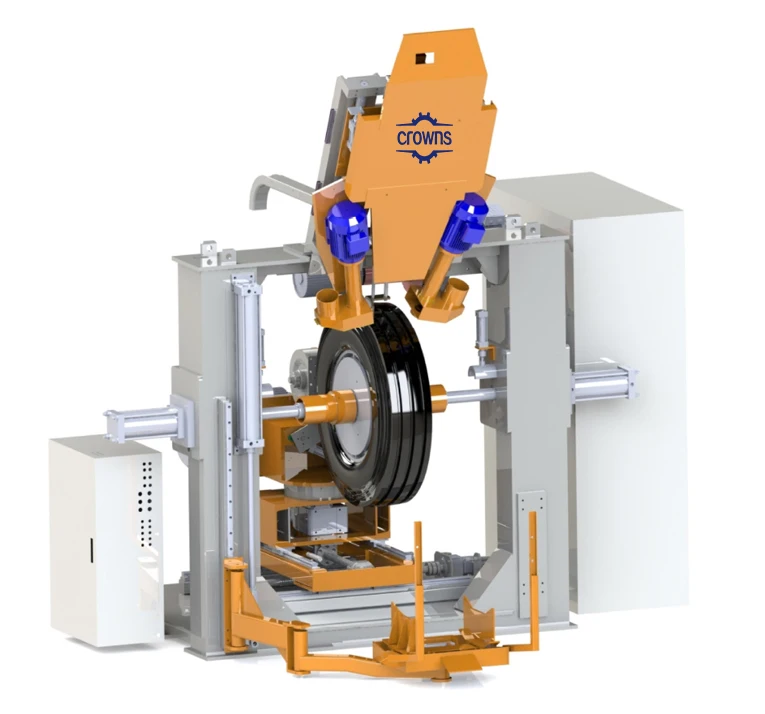

Tyre Retreading Machine/Buffing Machine

working process of the tyre retreading flow chart:

1.check out

Make sure the used tire casing can be accepted for retreading, or rejection.

2) Buffing

Buffing tire casing, buffing the worn tread rubber..

3) Planing

Remove all embedded objects in the casing, make sure the tire surface clean and solid, suitable for retreading.

4) Use glue gun

Use glue gun to spray a thin layer of concentrated liquid cement in the repair tire casings.

5) Glue filling

Fill in the repair cementing in the tire wound.

6) Apply the tread rubber

Apply the cushion gum between the tread rubber and the casing, as the bonding layer. As a new layer , the intensive precure tread rubber is forming in the tire casings

7) Assemble envelop

A special envelop is used to package the tires, ensure the tire casing and precure tread rubber successfully bond together

8) Curing

This is a process of applying the new tread rubber to the prepared tire casings, then put into curing chamber, in a certain pressure and temperature after a period of correct time curing, the cushion rubber layer will adhere tight to the tire casings.

9) Final inspection

Make sure all the recap been checked carefully, to ensure the safety and unharmed appearance of recycling products which sell to customers.

10) Everything looks "like new"

Now, end product! Safe and durable, is equally matched with the new tire. And ready to hit the road!

1.check out

Make sure the used tire casing can be accepted for retreading, or rejection.

2) Buffing

Buffing tire casing, buffing the worn tread rubber..

3) Planing

Remove all embedded objects in the casing, make sure the tire surface clean and solid, suitable for retreading.

4) Use glue gun

Use glue gun to spray a thin layer of concentrated liquid cement in the repair tire casings.

5) Glue filling

Fill in the repair cementing in the tire wound.

6) Apply the tread rubber

Apply the cushion gum between the tread rubber and the casing, as the bonding layer. As a new layer , the intensive precure tread rubber is forming in the tire casings

7) Assemble envelop

A special envelop is used to package the tires, ensure the tire casing and precure tread rubber successfully bond together

8) Curing

This is a process of applying the new tread rubber to the prepared tire casings, then put into curing chamber, in a certain pressure and temperature after a period of correct time curing, the cushion rubber layer will adhere tight to the tire casings.

9) Final inspection

Make sure all the recap been checked carefully, to ensure the safety and unharmed appearance of recycling products which sell to customers.

10) Everything looks "like new"

Now, end product! Safe and durable, is equally matched with the new tire. And ready to hit the road!

Item | 800 | 1200 | 1500 | 1700 | 2000 | 2600 |

Inner diameter(mm) | 800 | 1200 | 1500 | 1700 | 2000 | 2600 |

Canister length(mm) | 22000 | 3000 | 3000 | 4000 | 5000 | 10000 |

Number of lid sawtooth | 12 | 12 | 14 | 14 | 16 | 24 |

thickness of lid (mm) | 10 | 10 | 10 | 10 | 16 | 14 |

Thickness of the tank body(mm) | 10 | 10 | 10 | 10 | 12 | 14 |

Working pressure(Mpa) | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.55 |

Dimensions(m) | 2.2*1.4 *1.1 | 4.0*1.5 *1.6 | 3.9*2.1 *2.0 | 4.9*2.1 *2.1 | 6.2*2.5 *2.4 | 1.1*3.3 *4.1 |

Weight(Kg) | 5580 | 2017 | 2950 | 3835 | 6500 | 16775 |

The benefits of retreading are that it is both environmentally friendly and cost-efficient! When the tread has worn off, only about 20% of the tyre is used up. The carcass, which represents about 80% of the tyre's value, can be re-rubberized for a "new tyre life".

To produce a truck or bus tyre requires about 60-80 kg of rubber mixture. Retreading the tyre takes only about 15 kg of rubber. A considerable amount of raw materials can therefore be saved. In the EU, this equates to more than 300,000 tones per year!

To produce a car tyre requires about 28 litres of crude oil. To retread a car tyre, on the other hand, only 5.5 litres of oil are needed

To produce a truck or bus tyre requires about 60-80 kg of rubber mixture. Retreading the tyre takes only about 15 kg of rubber. A considerable amount of raw materials can therefore be saved. In the EU, this equates to more than 300,000 tones per year!

To produce a car tyre requires about 28 litres of crude oil. To retread a car tyre, on the other hand, only 5.5 litres of oil are needed

CROWNS MACHINERY

Qingdao crowns machinery co.,ltd was located in Huangdao District, the west coast of Qingdao city, Shandong province, China. We

are specialized in rubber and plastic machinery designing,manufacturing and maintenance work.we have been specializing in rubber and plastic machinery and production line for more than 30 years.

are specialized in rubber and plastic machinery designing,manufacturing and maintenance work.we have been specializing in rubber and plastic machinery and production line for more than 30 years.

CROWNS MAIN PRODUCTS

* Rubber mixing equipment: kneader mixing machine, bucket,mixing mill, bale cutter

* Rubber vulcanizing machine: Four-column press, Frame press, E-type press,vacuum molding press,injection press, tire and tube press, Belt vulcanizing press.

Rubber calendaring machine: 2 roll, 3 roll, 4 roll calender, calendaring line

Rubber extruding equipment: Hot feed extruder,cold feed extruder, belt extrudingand calendering line

* Rubber ,silicone,plastic products prdocuction line

* Automatic and semi-automatic waste tire recycling equipment

* Used tyre retreading machine line

* Rubber vulcanizing machine: Four-column press, Frame press, E-type press,vacuum molding press,injection press, tire and tube press, Belt vulcanizing press.

Rubber calendaring machine: 2 roll, 3 roll, 4 roll calender, calendaring line

Rubber extruding equipment: Hot feed extruder,cold feed extruder, belt extrudingand calendering line

* Rubber ,silicone,plastic products prdocuction line

* Automatic and semi-automatic waste tire recycling equipment

* Used tyre retreading machine line

Q1: Where is your factory located?

A1: Qingdao crowns machinery co.,ltd is located at Huangdao district ,Qingdao city, China

Q2: Are you an integrated supplier for rubber&plastic machine ?

A2: Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3: How about the quality control in your factory?

A3: Qingdao crowns has the SOP (Standard Operation Procedure) and all the production step must follow up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully before shipment.

Q4: Will you offer the pre-sales service?

A4: Yes, we have an experienced pre-sales team to support customers not only including machine, technology also water

.electrical,machine layout in factory, etc.

Q5: What about the after-service? Will you send your engineer to my country to help commission and install the machine?

A5: Surely, we have many experience technical engineers for oversea service, they would help you install machine and support training to workers also.

Q6: What is the delivery time of the machine?

A6: Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery time of standard machine could be within 10-30 days

Q7 : What is the warranty of the machine ?

A7: The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Do you provide any spare parts with machine?

A8: Yes, CROWNS will provide one set standard spare parts to customer according to different machines

A1: Qingdao crowns machinery co.,ltd is located at Huangdao district ,Qingdao city, China

Q2: Are you an integrated supplier for rubber&plastic machine ?

A2: Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3: How about the quality control in your factory?

A3: Qingdao crowns has the SOP (Standard Operation Procedure) and all the production step must follow up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully before shipment.

Q4: Will you offer the pre-sales service?

A4: Yes, we have an experienced pre-sales team to support customers not only including machine, technology also water

.electrical,machine layout in factory, etc.

Q5: What about the after-service? Will you send your engineer to my country to help commission and install the machine?

A5: Surely, we have many experience technical engineers for oversea service, they would help you install machine and support training to workers also.

Q6: What is the delivery time of the machine?

A6: Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery time of standard machine could be within 10-30 days

Q7 : What is the warranty of the machine ?

A7: The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Do you provide any spare parts with machine?

A8: Yes, CROWNS will provide one set standard spare parts to customer according to different machines

Похожие товары

Машина для полировки шин для грузовых автомобилей

US $20000-$50000

Камера

US $20000-$50000

Ручная машина для строительства шин

US $10000-$20000