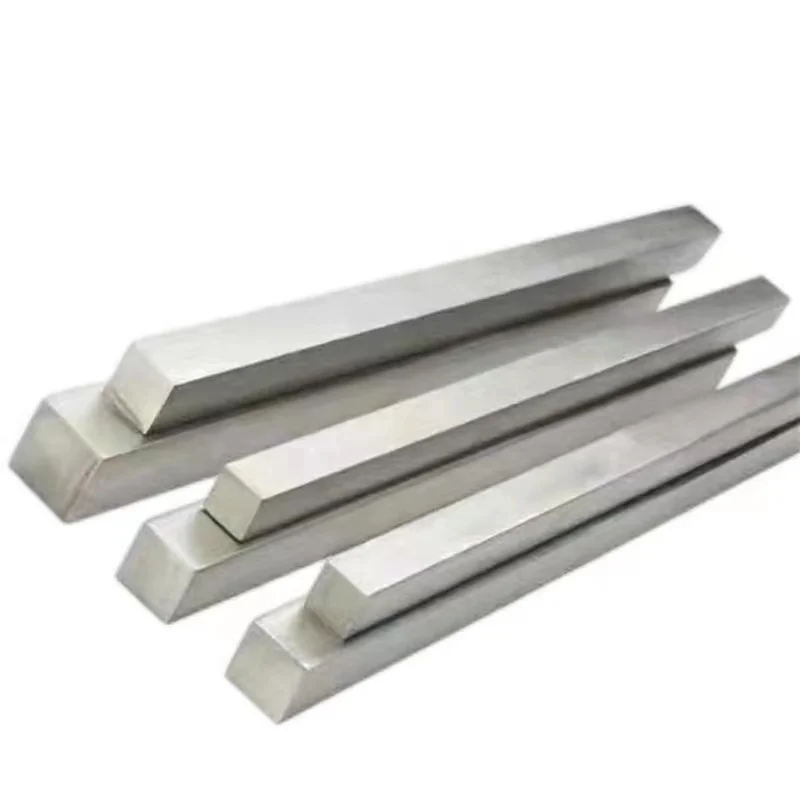

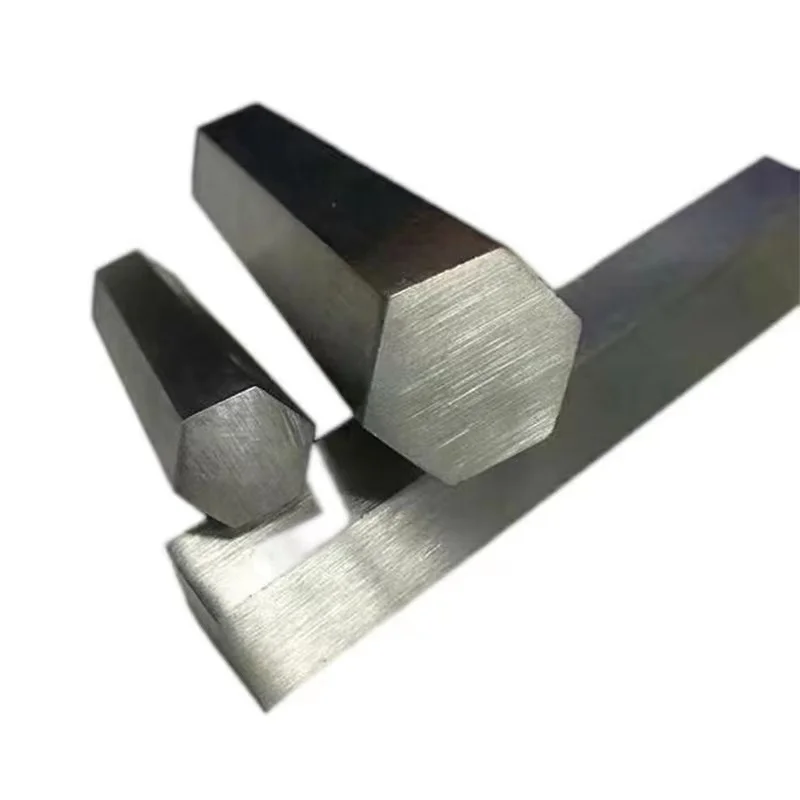

Oem твердый серебристо-серый чистый кованый титановый квадратный

- Категория: Titanium Bars >>>

- Поставщик: Qingdao,O.b.t,Manufacture,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 12.11 $* | 13.8 $* |

| Aug-16-2025 | 12.59 $* | 13.68 $* |

| Jul-16-2025 | 10.67 $* | 11.90 $* |

| Jun-16-2025 | 12.22 $* | 13.85 $* |

| May-16-2025 | 10.18 $* | 11.36 $* |

| Apr-16-2025 | 11.25 $* | 12.57 $* |

| Mar-16-2025 | 11.81 $* | 12.18 $* |

| Feb-16-2025 | 11.99 $* | 12.89 $* |

| Jan-16-2025 | 11.93 $* | 12.23 $* |

Характеристики

Product Description

Product Name | Shandong Inconel690 Cnc Machining Plating Titanium Baffle Tube Wire Sheet Pipes Bars |

Material | TA1, TA2, TA3, TA4, TA5, TA6, TA7, TA8, TA9, TA10, TA11, TA12, TA13, TA14, TA15, TA15-1, TA15-2, TA16, TA17, TA18, TA19, TA20, TA21, TA22, TA23, TA24, TA25, TA26, TA27, TA28; |

TB2, TB3, TB4, TB5, TB6, TB7, TB8, TB9, TB10, TB11; | |

TC1, TC2, TC3, TC4, TC5, TC6, TC8, TC9, TC10, TC11; | |

Ti-6Al-4V, Ti-5Al-2.5Sn, Ti-2Al-2.5Zr, Ti-32Mo, Ti-Mo-Ni, Ti-Pd, SP-700, Ti-6242, Ti-10-5-3, Ti-1023, BT9, BT20, IMI829, IMI834 etc. | |

Place of Origin | Qingdao, Shandong, China |

Processing Craft | Drawing→ Mold design→ Mold manufacturing→ Wax pressing→ Wax Repairing→ Tree Grouping→ Shell Making (paste)→ Dewaxing→ Shell Roasting→ Chemical Analysis→ Pouring→ Cleaning→ CNC machining→ Molding→Packaging→ Delivery |

Surface Treatment | Electroplating, Chrome Plating, Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Powder coating, Sandblasting, Passivation, Spray painting, Etc. |

Tolerance | ± 0.01mm |

Type | Precision casting, lost Wax Casting, investment casting, plaster casting, ceramic mold casting, metal mold casting |

OEM; Customized | |

Certification | ISO9001:2015 Certified, UL Certification |

Packing | Carton/Wooden box |

Inspection | 1.Foundry in-house: 100% inspection on critical dimension; 100% on appea rance. |

2.Third Party inspection available upon requirement. | |

Service | Drawing Custom |

Mainly Testing Facility | Three-dimensional measuring instrument (CMM), Salt spray test box, Dynamic balance detector, Pneumatic detection |

Quality Guarantee | 2 Years |

Features & Advantage | 1.High machining accuracy, the flatness within 0.1mm |

2.High finish appearance, smooth surface roughness is Ra1.6 after machining. | |

3.The machining precision is high and the assembly structure is seamless. | |

4.Smooth appearance, corrosion resistance. | |

5.Pass Salt Spray Test with 144 Hours. | |

Standard | 1.Aluminum alloy : ISO3522-84, ASTMB85-96, ASTMB597-98 |

2.Magnesium alloy : ISO/DIS16220-1999, ASTMB93/B93M-98,JISH2222-1991 | |

3.Zinc alloy: ISO301-1981, ASTMB86-98, ASTMB240-98, ASTMB327-98 | |

Payment | L/C,D/A,D/P,T/T,Western Union,Money Gram |

Packing & Delivery

Packaging Details

Inside: anti-rust packing.

Weight: 15 kg per carton

Outside: Packed with free fumigating wooden case

Inside: anti-rust packing.

Weight: 15 kg per carton

Outside: Packed with free fumigating wooden case

Company Profile

Q1.Are you trading company or manufacturer?

A:We are factory.

Q2.How Can I order?

A:You can directly place an order on our shop in Alibaba web. Or you can tell us the model no of the products you like, then we will send you the question.

Q3.How does your factory do regarding quality control?

A:Quality is priority. Our people always attach great importance to quality. Controlling from the production beginning to theend.We have well-trained and professional workers and strict QC system in each production link. And each product has to be 100%

inspected before shipment.

A:We are factory.

Q2.How Can I order?

A:You can directly place an order on our shop in Alibaba web. Or you can tell us the model no of the products you like, then we will send you the question.

Q3.How does your factory do regarding quality control?

A:Quality is priority. Our people always attach great importance to quality. Controlling from the production beginning to theend.We have well-trained and professional workers and strict QC system in each production link. And each product has to be 100%

inspected before shipment.

Q4: Have you ever made an order on Alibaba?

A:Our trade assurance assigned by Alibaba is 530,000 USD to guarantee 100% premium protection; 100% on time shipment and 100%

payment security.

Q5.What is your greatest strength?

Accuracy 0.004mm

SGS,IS0,CE,Tuv Certificates

Smooth surface roughness is Ra1.6

Titanium ,superalloy,aluminium stainless steel, etc

Q6.What is the price?

For an accurate quote, please provide us with more details like logo or packaging customization requirements, quantity preference,

shipping address, etc.

A:Our trade assurance assigned by Alibaba is 530,000 USD to guarantee 100% premium protection; 100% on time shipment and 100%

payment security.

Q5.What is your greatest strength?

Accuracy 0.004mm

SGS,IS0,CE,Tuv Certificates

Smooth surface roughness is Ra1.6

Titanium ,superalloy,aluminium stainless steel, etc

Q6.What is the price?

For an accurate quote, please provide us with more details like logo or packaging customization requirements, quantity preference,

shipping address, etc.

Win the future OBT:

OBT is founded in 2003, as the leading manufacturer and exporter in the lost wax casting ,die casting and sand casting industry for 19 years old, abiding by the corporate philosophy superior quality, reasonable price and perfect after-sales service, relying on exquisite R&D research and Germany manufacturing technology.

Abiding by the Corporate philosophy superior quality, reasonable price and perfect after-sales service, relying on exquisite research and manufacturing technology, we O.B.T provide the safest productions for our clients to help them develop the market.

O.B.T has got ISO9001 international system certificate and CE security certificate and supplied our best productions and service to South-east Asia, Europe, South America, Australia and Africa market successfully, and has won wide acclaim from customers.

In the future, O. B. T Group will constant adhering to the business philosophy of people-oriented, customer first, make persistent efforts to strengthen product development and take the advantage of group superiority, with the latest technology and perfect quality, we would develop the international market vigorously to provide a one-stop comprehensive solution to our client.

OBT is founded in 2003, as the leading manufacturer and exporter in the lost wax casting ,die casting and sand casting industry for 19 years old, abiding by the corporate philosophy superior quality, reasonable price and perfect after-sales service, relying on exquisite R&D research and Germany manufacturing technology.

Abiding by the Corporate philosophy superior quality, reasonable price and perfect after-sales service, relying on exquisite research and manufacturing technology, we O.B.T provide the safest productions for our clients to help them develop the market.

O.B.T has got ISO9001 international system certificate and CE security certificate and supplied our best productions and service to South-east Asia, Europe, South America, Australia and Africa market successfully, and has won wide acclaim from customers.

In the future, O. B. T Group will constant adhering to the business philosophy of people-oriented, customer first, make persistent efforts to strengthen product development and take the advantage of group superiority, with the latest technology and perfect quality, we would develop the international market vigorously to provide a one-stop comprehensive solution to our client.

FAQ

Our Advantages

Похожие товары

Титановый стержень Ti6al4v класса 5, цена за кг

US $20.70-$22.30

Высококачественный чистый 99.99% gr2 титановый стержень

US $12.85-$19.85

10 мм 20 мм 30 мм Диаметр ниобиевого титанового сплава, цена за фунт

US $61.40-$61.60

Нержавеющая сталь gr2 класс 23 титановый круглый бар цена за кг

US $20.00-$45.00