Горячая распродажа гравиметрический блендер пластиковый винтовой миксер большой емкости для литья

- Категория: Plastic Raw Material Machinery >>>

- Поставщик: Dongguan,Mingkai,Electromechanical,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 4867.70 $* | 5110.88 $* |

| Aug-15-2025 | 4826.61 $* | 5067.5 $* |

| Jul-15-2025 | 4049.57 $* | 4251.75 $* |

| Jun-15-2025 | 4744.78 $* | 4981.42 $* |

| May-15-2025 | 4131.31 $* | 4338.55 $* |

| Apr-15-2025 | 4663.18 $* | 4896.24 $* |

| Mar-15-2025 | 4622.90 $* | 4853.77 $* |

| Feb-15-2025 | 4581.36 $* | 4810.57 $* |

| Jan-15-2025 | 4540.60 $* | 4767.85 $* |

Характеристики

Product Overview

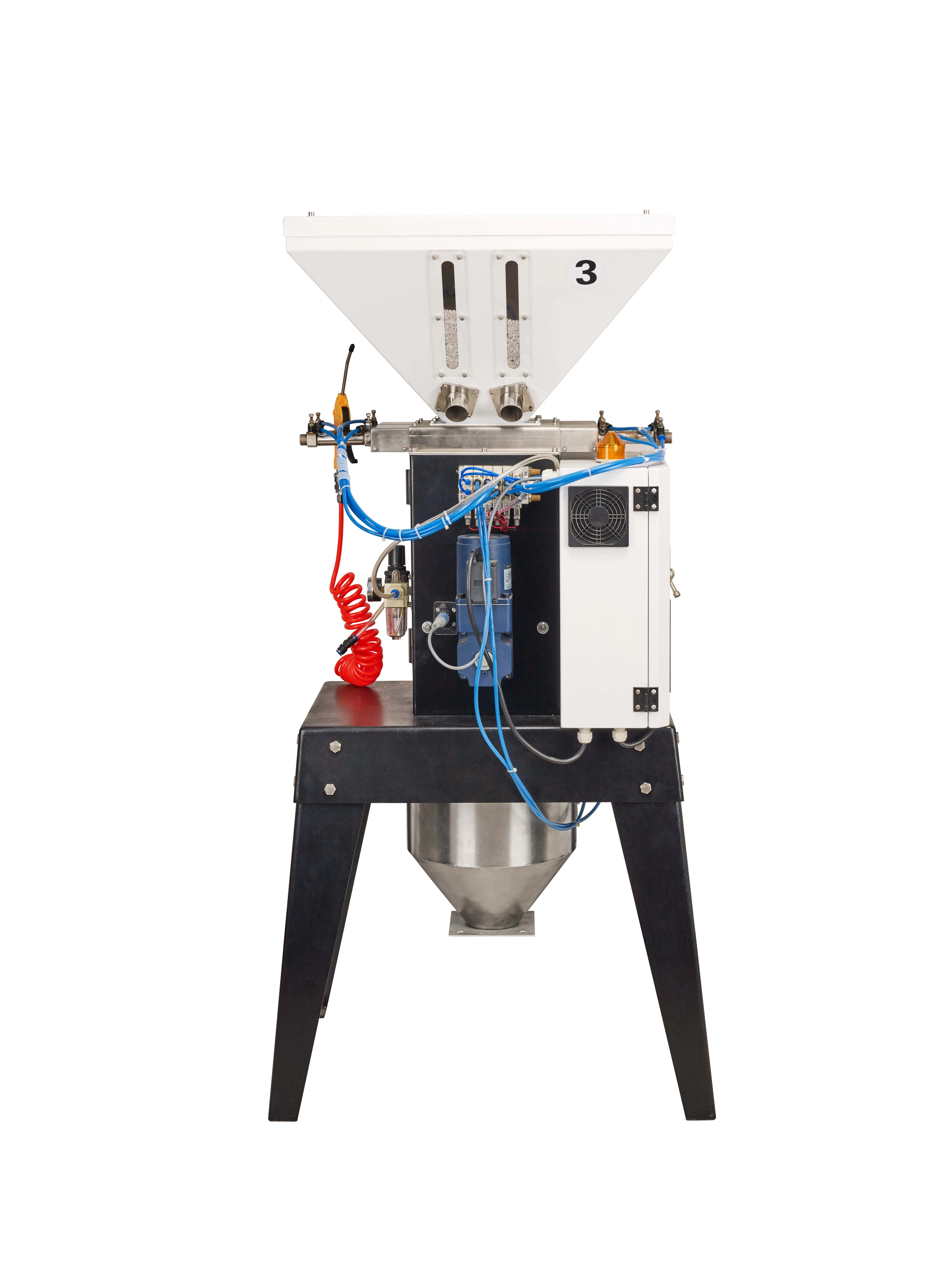

Automatic batching and weighing system of automatic masterbatch metering mixer for weighing mixer of manufacturer

This series of weighing mixer is suitable for the occasions where many kinds of raw materials are needed for plastic injection,extrusion or hollow molding, and they are accurately mixed according to the weight ratio. The controller of this series of products adopts Siemens PLC control system in Germany and adopts advanced batching algorithm, which can automatically calibrate every time it is turned on to ensure the accuracy, and the operation is easy to learn and convenient.

FEATURES AT A GLANCE

Right elevation

Left elevation

Front elevation

principle of operation

When the machine starts to work, the metering valve of the main material barrel is opened according to the set weight value and

the time value calculated by the metering valve. When the blanking time arrives, the metering valve is closed to detect the weight

of the weighing pan. If it is within the error range of the set blanking value, the next drum is switched for metering, and so on

until the blanking of each drum is completed. After discharging, the weighing tray valve is opened, the raw materials fall into

the mixing barrel, and the agitator is started to stir until the set stirring time is reached, and the agitator stops, and the

baffle plate is manually opened or the discharging valve is automatically opened to make the stirred raw materials fall into the

injection molding machine or the storage barrel, and so on.

the time value calculated by the metering valve. When the blanking time arrives, the metering valve is closed to detect the weight

of the weighing pan. If it is within the error range of the set blanking value, the next drum is switched for metering, and so on

until the blanking of each drum is completed. After discharging, the weighing tray valve is opened, the raw materials fall into

the mixing barrel, and the agitator is started to stir until the set stirring time is reached, and the agitator stops, and the

baffle plate is manually opened or the discharging valve is automatically opened to make the stirred raw materials fall into the

injection molding machine or the storage barrel, and so on.

PRODUCT SPECIFICATIONS

model | Anverage throughput | Batch Capacity | Total power | Main material | Additive ratio | Material hopper | Mixing chamber |

CGB-50 | 50 | 0.6 | 0.12 | 5-100 | 0.5-10 | 18 | 6 |

CGB-100 | 100 | 1.2 | 0.12 | 5-100 | 0.5-10 | 32 | 20 |

CGB-200 | 200 | 2.2 | 0.25 | 5-100 | 0.5-10 | 32 | 20 |

CGB-400 | 400 | 4.5 | 0.25 | 5-100 | 0.5-10 | 45 | 20 |

CGB-600 | 600 | 8 | 0.55 | 5-100 | 0.5-10 | 70 | 40 |

CGB-800 | 800 | 8 | 0.55 | 5-100 | 0.5-10 | 100 | 40 |

CGB-1200 | 1200 | 12 | 1.5 | 5-100 | 0.5-10 | 130 | 80 |

CGB-2000 | 2000 | 20 | 1.5 | 5-100 | 0.5-10 | 160 | 80 |

CGB-2500 | 2500 | 25 | 1.5 | 5-100 | 0.5-10 | 180 | 100 |

CGB-3000 | 3000 | 30 | 3 | 5-100 | 0.5-10 | 230 | 180 |

Our factory

Our Services

PRODUCT CONFIGURATION

FAQ

1. What is the warranty of your machine?

R: 1 years, any product itself question,you can contact with us.

2. What is the material of your machine , is oil free?

R: our machine is aluminum alloy, motor is 100% copper coil , of course, we are oil free.

3. How to operate your machine?

R: Connect with wire, and turn on the power, so you can use it directly, about the wiring method, we will tell you how to do

according to your voltage, so at first , you need to tell us your voltage and phase,its important.

4. You are trading company or manufacture?

R: We are manufacture, we can provide long-term supply with fast speed.

5. How to contact with you?

R: You can send messages to me directly by alibaba trade manager, or add me like below

R: 1 years, any product itself question,you can contact with us.

2. What is the material of your machine , is oil free?

R: our machine is aluminum alloy, motor is 100% copper coil , of course, we are oil free.

3. How to operate your machine?

R: Connect with wire, and turn on the power, so you can use it directly, about the wiring method, we will tell you how to do

according to your voltage, so at first , you need to tell us your voltage and phase,its important.

4. You are trading company or manufacture?

R: We are manufacture, we can provide long-term supply with fast speed.

5. How to contact with you?

R: You can send messages to me directly by alibaba trade manager, or add me like below