Трехрулонная мельница лабораторная чернильная пигментная мазь Электронная паста для мыла помада косметическая пудра тройная

- Категория: Grinding Equipment >>>

- Поставщик: Dongguan,Strong,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.25 $* | 0.3 $* |

| Aug-19-2025 | 0.23 $* | 0.59 $* |

| Jul-19-2025 | 0.4 $* | 0.21 $* |

| Jun-19-2025 | 0.88 $* | 0.22 $* |

| May-19-2025 | 0.56 $* | 0.27 $* |

| Apr-19-2025 | 0.73 $* | 0.72 $* |

| Mar-19-2025 | 0.4 $* | 0.59 $* |

| Feb-19-2025 | 0.72 $* | 0.79 $* |

| Jan-19-2025 | 0.73 $* | 0.0 $* |

Характеристики

Product Description

Application:

Root lab use three roller mill is widely applied in institute experiment and trail production of paint, dye, printing ink, cosmetics, rubber, soap, high viscosity pulp, agriculture chemicals, ceramic, adhesion and grinding paste slurry etc. Laboratory three roller grinding mill is currently one of the most popular grinding mill for paint, UV ink production.

Working Principle:

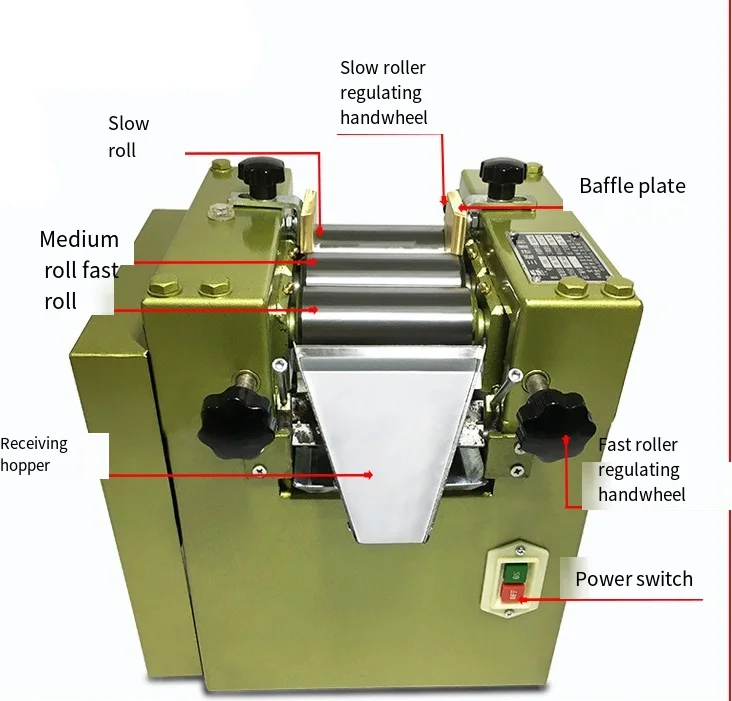

The equipment consists of three rollers fixed on the frame and driven directly by the motor. The rotation direction between rollers is generally different, the front roller rotates forward while the rear roller rotates backword. The speed of front roller is quicker while speed of rear roller is slower. The middle roller is fixed, and the front and rear rollers are mounted on the slide with spring device. Adjust the distance between three roll62ers by adjusting the hand wheel. The material discharged from space between rear roller and middle roller, are squeezed by the rollers to obtain smaller particle size. Then the material are rolled out by the fast roll(Roll rotates at high speed). The scrapper at the end of the fast roller separate material from the roller and fall into the collection barrels. Since it produces a lot of heat in the grinding process, the center of each roller is hollow. Input water for cooling to ensure finished products with good quality.

Root lab use three roller mill is widely applied in institute experiment and trail production of paint, dye, printing ink, cosmetics, rubber, soap, high viscosity pulp, agriculture chemicals, ceramic, adhesion and grinding paste slurry etc. Laboratory three roller grinding mill is currently one of the most popular grinding mill for paint, UV ink production.

Working Principle:

The equipment consists of three rollers fixed on the frame and driven directly by the motor. The rotation direction between rollers is generally different, the front roller rotates forward while the rear roller rotates backword. The speed of front roller is quicker while speed of rear roller is slower. The middle roller is fixed, and the front and rear rollers are mounted on the slide with spring device. Adjust the distance between three roll62ers by adjusting the hand wheel. The material discharged from space between rear roller and middle roller, are squeezed by the rollers to obtain smaller particle size. Then the material are rolled out by the fast roll(Roll rotates at high speed). The scrapper at the end of the fast roller separate material from the roller and fall into the collection barrels. Since it produces a lot of heat in the grinding process, the center of each roller is hollow. Input water for cooling to ensure finished products with good quality.

Machine Parameter

Model | S65 |

Roller Diameter | 65 mm |

Roller working face Length | 125 mm |

Rotation speed | Fast roller = 250 RPM |

Middle roller = 89 RPM | |

Slow roller =32 RPM | |

Electric motor | 0.75 KW |

Kind of Package | packed in plywood case |

Packing & Delivery

Packing:

Machine packing inside is plastic films and outside is fumigation wooden case.

Our wooden case is very strong,it can bear long time shipping on the sea.

And machine with preservative film, it can stop the salt sea water enter into the machine and make the machine corrosion.

Our wooden case is very strong,it can bear long time shipping on the sea.

And machine with preservative film, it can stop the salt sea water enter into the machine and make the machine corrosion.

Delivery:

For machines are big and heavy parcel, and different country with different delivery cost,so we suggest below delivery

solution:

1. Over 1CBM or 100KG, we suggest send by Sea.

2. Below 1CBM or 100KG, we suggest send by Air.

3. Below 0.5CBM or 50KG, we suggest send by Express.

The price show on our website just the machine EXW price, please contact us for confirm delivery cost before you place order.

1. Over 1CBM or 100KG, we suggest send by Sea.

2. Below 1CBM or 100KG, we suggest send by Air.

3. Below 0.5CBM or 50KG, we suggest send by Express.

The price show on our website just the machine EXW price, please contact us for confirm delivery cost before you place order.

Company Profile

Shenzhen Strong Machine Co., Ltd. has been committed to R&D, production and sales of the packing machine field ever since its establishment in 1995.

We are professional designer and manufacturer of High Frequency Welding Machine, Ultrasonic Plastic Welding Machine, Blister Forming Machine, Tube Sealing and Filling Machine and other Packing Machine with over 15 years.

We welcome both new and regular customers at home and abroad to visit us and cooperate with us to achieve mutual profits and create a better future. We are convinced that your partnership with us can help your business scale a new high.

We are professional designer and manufacturer of High Frequency Welding Machine, Ultrasonic Plastic Welding Machine, Blister Forming Machine, Tube Sealing and Filling Machine and other Packing Machine with over 15 years.

We welcome both new and regular customers at home and abroad to visit us and cooperate with us to achieve mutual profits and create a better future. We are convinced that your partnership with us can help your business scale a new high.

Certifications

Since its inception, STRONG MACHINE has been devoted to optimization and integration of developing, producing, sealing, and application of technology of ultrasonic machinery. After almost twenty years of unremitting efforts, STRONG MACHINE with high quality products, excellent technical support and perfect after-sales service has established a good reputation among the customers, and also gains a number of provincial and national honnors.

FAQ

Q: Are you trading company or manufacturer ?

A:Yes, We are factory, all machine is made by ourself and we can provide customize service according to your requirement.

Q: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

Q:What should I do if we are not able to operate the machine when we receive it?

A:Operation manual and video demonstration sent along with the machine to give instructions. Besides, we have professional after-sale group to customer's site to solve any problems.

Q: How could I get the spares on machines?

A: We will send extra sets of easy broken spares and accessories etc. Non-artificial damaged spares will be sent freely and shipping free during 1 year's warranty.

Q: Is there any installation direction after we received the machine?

A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.

Q: Is there any ensurance to guarantee my order from your company?

A: We are an onsite check factory from Alibaba, and the quality, delivery time, your payment are all ensured by Alibaba trade assurance. The machine will have two years warranty. During the warranty year if any of the parts broken not by man-made. We will free charge to replace the new one to you . The warranty will begin after the machine send out we received the B/L .

A:Yes, We are factory, all machine is made by ourself and we can provide customize service according to your requirement.

Q: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

Q:What should I do if we are not able to operate the machine when we receive it?

A:Operation manual and video demonstration sent along with the machine to give instructions. Besides, we have professional after-sale group to customer's site to solve any problems.

Q: How could I get the spares on machines?

A: We will send extra sets of easy broken spares and accessories etc. Non-artificial damaged spares will be sent freely and shipping free during 1 year's warranty.

Q: Is there any installation direction after we received the machine?

A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.

Q: Is there any ensurance to guarantee my order from your company?

A: We are an onsite check factory from Alibaba, and the quality, delivery time, your payment are all ensured by Alibaba trade assurance. The machine will have two years warranty. During the warranty year if any of the parts broken not by man-made. We will free charge to replace the new one to you . The warranty will begin after the machine send out we received the B/L .

Pre-sale services:

1. Providing professional technical support.

2. Send the product catalog and instruction manual.

3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!

4. Personal call or visit are warmly welcome

2. Send the product catalog and instruction manual.

3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!

4. Personal call or visit are warmly welcome

Sale of services:

1. We promise honest and fair, it's our pleasure to serve you as your purchasing consultant.

2. We guarantee punctuality, quality and quantities strictly implement the terms of contract.

2. We guarantee punctuality, quality and quantities strictly implement the terms of contract.

After-sales service:

1. Where to buy our products for 1 years warranty and life long maintenance.

2. 24-hours telephone service.

3. A large stock of components and parts, easily-worn parts

2. 24-hours telephone service.

3. A large stock of components and parts, easily-worn parts