Проволока обернутый экран трубы

- Категория: Other Welding Equipment >>>

- Поставщик: Henan,Wadley,CNC,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 83300.4 $* | 87465.22 $* |

| Aug-16-2025 | 82600.59 $* | 86730.33 $* |

| Jul-16-2025 | 69300.9 $* | 72765.2 $* |

| Jun-16-2025 | 81200.14 $* | 85260.27 $* |

| May-16-2025 | 70700.75 $* | 74235.41 $* |

| Apr-16-2025 | 79800.72 $* | 83790.81 $* |

| Mar-16-2025 | 79100.6 $* | 83055.62 $* |

| Feb-16-2025 | 78400.27 $* | 82320.56 $* |

| Jan-16-2025 | 77700.23 $* | 81585.10 $* |

Характеристики

Product Overview

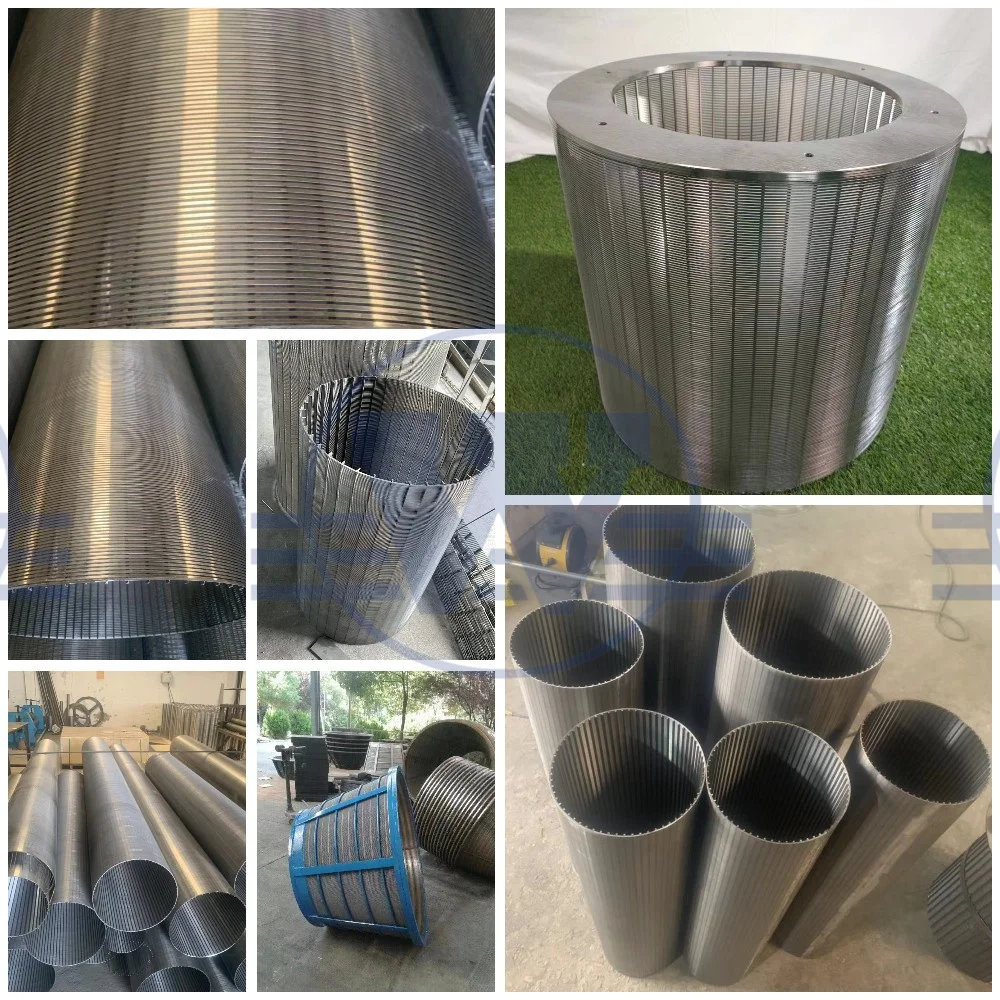

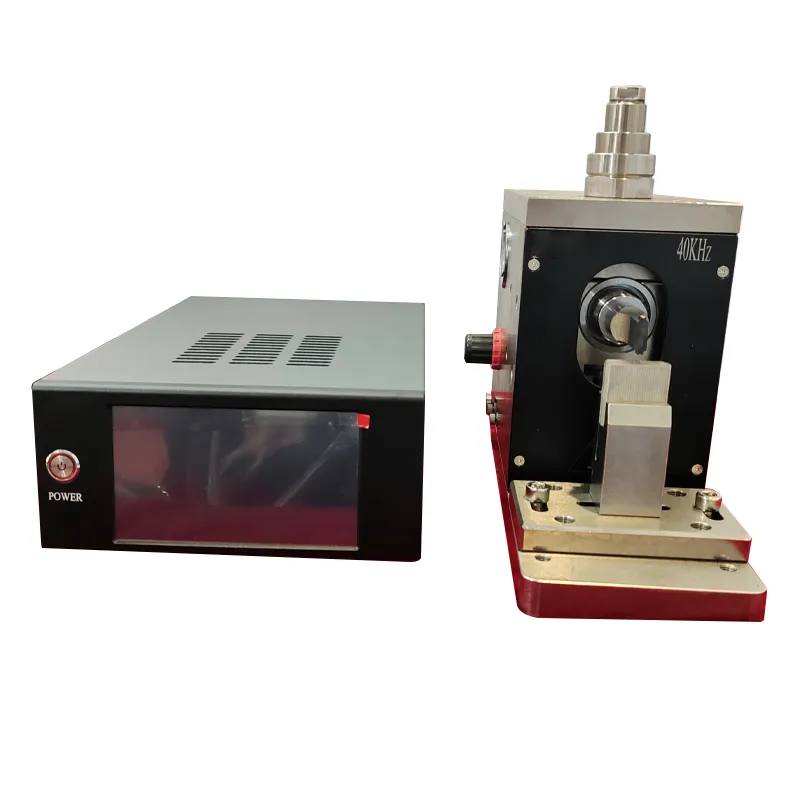

Stainless Steel Johnson Wedge Wire Screen Tube Pipe Welder Filter Making Welding Machine

The Wedged Wire Johnson Screen Welding Machine feature of low noise, less power consumption stable performance and safety. The equipment can be designed and manufactured according to the specifications required by users, using advanced electrical control system, with mesh gap, drum speed and length of mesh being watched at any time and being adjusted without stopping. The equipment is of power-saving, low carbon and environment-friendly, stable and reliable product quality. It is an ideal equipment for the production of petroleum filter screen, coal mine screen bar, sewage treatment, water well filter pipe and food industry

Function Characteristics:

1. Our wedged wire screen mesh welding machine have the strong point of low noise, low energy consumption and stable function.

2. The electrical control system is researched and developed by ourselves; main axis and feeding axis are both adopt Panasonic Brand AC power servo motor and drivers.

3. Slot size adopt NC servo motor to drive ball-screws. Ball-screws drive the drawing support rods plate sliding on linear

guideway according to the instructions, slot size could be adjusted randomly.

4. Machine parameters display visually and conveniently, simple and easy to do. Ball-screws and linear guideway both adopt import famous brand products.

1. Our wedged wire screen mesh welding machine have the strong point of low noise, low energy consumption and stable function.

2. The electrical control system is researched and developed by ourselves; main axis and feeding axis are both adopt Panasonic Brand AC power servo motor and drivers.

3. Slot size adopt NC servo motor to drive ball-screws. Ball-screws drive the drawing support rods plate sliding on linear

guideway according to the instructions, slot size could be adjusted randomly.

4. Machine parameters display visually and conveniently, simple and easy to do. Ball-screws and linear guideway both adopt import famous brand products.

Material:stainless steel wire.

mine sieving mesh is newly developing products in wire mesh industry.they have the characteristics of easy to teak,wear resisting,corrosion-resising,the cross section of net trapezoidal the top is narrow,the under is wide,widely used in mine,coal,petroleum,fertilizer,grain,salt,environmental protection.etc.

specification

Model | WL-200x2000 | WL-300x6000 | WL-600x6000 | WL-1200x1400 | |||

Screen diameter | 50-200mm | 80-300mm | 200-600mm | 600-1200mm | |||

Wire range | 0.75-1.5mm | 1.2-3mm | 1.2-3mm | 1.5-5mm | |||

Screen length | 2000mm | 6000mm | 6000mm | 4000mm | |||

Welding transfer power | 100KVA | 200KVA | 200KVA | 20KVA | |||

Welding speed | 6-30rpm | 6-40rpm | 6-30rpm | 6-20rpm | |||

Clearance of slot | 0.05-5mm | 0.1-16mm | 0.2-16mm | 6-20mm | |||

Wire material | S304,S201,SAE1006 etc. | ||||||

Voltage | 3 phase,380V/220V/440V/415V/600V,50/60Hz | ||||||

Welding transformer | 100kw | ||||||

Welding precision | If wire tolerance is within 0.01mm,welding precision will be within ±0.04mm | ||||||

Dimension | 6*1.5*3.3m | 13*1.5*3.3m | 13*1.5*3.3m | 11*2.1*3.8m | |||

Weight | 8000kg | 11000kg | 13000kg | 15600kg | |||

· We can design the machine according to your Screen diameter, Screen length and Slot size.

Product Show

Wedged Wire Screen Mesh Welding Machine

The electrical control system of the machine is Mitsubishi or Siemens. The feed shaft and main shaft are AC servo motors and Mitsubishi or Siemens drivers. Controlled by control system the drum rotates synchronized with drawing device, which is driven by the servo motor. The clearance (slot) can be adjusted according to the requirement, so as to ensure the uniformity of slots. The retractable display screen makes it easy to change parameters and display.

Johnson Wedge Wire Screen Welding Machine

The Johnson pipe welding machine, also called water well screen welding machine, Deep well screen making machine, used to make wedged wire wrapped screen, mineral filtrating mesh, coal washing mesh, water filtration mesh, water well screen etc.

Wedged Wire Screen Winding Welding Machine

Each machine is equipped with a locking expanding ring, which is used to expand the whole ring after the rods are put. When one filter tube is finished, you needn't to cut the rods, so the material consumption is less, and less time is needed. It is an ideal equipment for the production of petroleum filter screen, coal mine screen bars, sewage treatment, water well filter pipes and food industry.

Automatic Wedge Wire Screen Pipe Welding Machine

Our products, wire welding machines, are of low noise, less power consumption, stable performance and safety. They can be designed and manufactured according to the specifications required by users. Machines adopt advanced electrical control system, with slot, running speed and length of the welded filter tube being watched and adjusted any time without stopping the machine.

Machine Parts Detail

Johnson wedge wire screen welding machine

1. The CNC screen welding machine produced by our company has low noise, low power consumption, stable performance and dust-proof safety.

2. The control system of the equipment is a special program independently developed by our company. The gap of the seam can be arbitrarily adjusted according to the actual situation.

3. The net seam uses the servo motor to drive the ball screw, and the screw drives the drag disk to slide on the linear guide

according to the instruction, and the feed axis and the spindle of the device are all driven by the servo motor.

4. Ball screws and linear guides are imported brand-name products, and the equipment parameters display convenient and intuitive, simple and easy, accurate positioning, stable performance.

3. The net seam uses the servo motor to drive the ball screw, and the screw drives the drag disk to slide on the linear guide

according to the instruction, and the feed axis and the spindle of the device are all driven by the servo motor.

4. Ball screws and linear guides are imported brand-name products, and the equipment parameters display convenient and intuitive, simple and easy, accurate positioning, stable performance.

Application

Wire welding machines can be used for producing special filter screen cylinders, screen plates, screen baskets, screen bars, vibration screens, arc screens, filters, oil sand filter casing, flour screens, seawater desalinations, sewage disposals, and pulp filters. The products of the machines can be used for fruit juice, distillery raw materials filtration, water well filtration, gold mine. sewage pipeline blocks.

Industries: petroleum, coal mining, distillery, sewage treatment of juice plants, desalination, flour mills, paper mills, gold mines, highway management.

Water filter tube:

1. Material: SUS302, 304, 304L,306 stainless steel and low carbon steel wire etc

2. Features: Welded filter tube is composed of two parts: support strip---rod, and winding wire----Wire. The support rod can be round or triangular or trapezoidal.wire is a triangular wire (V-shaped wire) with precise slot size and high filtration precision. The filter tube has the characteristics of strong structure, high temperature resistance,corrosion resistance, good mechanicallong service life safety and reliability, etc. They can be used for many kinds of media filtration.

3. Application: the water filter pipe is a kind of porous water flter equipment, which can be used in deep water wells, submersible pumps, water treatment equipment, environmental protection, desalination treatment of seawater into industrial water and domestic water, tap water treatment, water softening treatment, terminal fltration of petroleum products,filtration of chemical acid and alkali liquids, recovery and filtration of alcohol and other organic solutions.

4. Product performance: Continuous slots greatly increase the area of overflowing water and therefore make better contact with the water.

5. We can provide products in the range of tube diameter 80-500mm, slot 0.1-10mm, length 50-5850mm.

Petroleum sand control filter

1. Outer tube can be stainless steel screen, stainless steel plate punched spiral welded pipe or stainles steel V-wire wound

welded pipe. Base pipe adopts AP standard casing or tubing, material is J55 or N80 oil pipe, high strength and not easily

deformed.

welded pipe. Base pipe adopts AP standard casing or tubing, material is J55 or N80 oil pipe, high strength and not easily

deformed.

2. The slots are uniformly smooth and burr-free.

3. A dense protective layer is formed on the surface of the sieve tube by the whole anticorrosion treatment, which improves the performance and the corrosion resistance of the filter tube. The working life of the pipe can be effectively extended.

4. Simple operation, convenient use, large inner diameter, easy to wear through the pipe.

Company Profile

Henan Wadley CNC Machinery Co.,Ltd..

Henan Wadley CNC Machinery Co.,Ltd. is a manufacture specializing in custom cold roll forming equipment and automatic production lines,we can manufacture hundred types roll forming machines and all kinds of architecture profliles.Engineers and technicians are rich in experience of designing developing and manufacturing of machines to provied customers with customized designs.Our products and sold to many countries and regions around the world.and we have established long-term cooperative relationships with customers.

Henan Wadley CNC Machinery Co.,Ltd. is a manufacture specializing in custom cold roll forming equipment and automatic production lines,we can manufacture hundred types roll forming machines and all kinds of architecture profliles.Engineers and technicians are rich in experience of designing developing and manufacturing of machines to provied customers with customized designs.Our products and sold to many countries and regions around the world.and we have established long-term cooperative relationships with customers.

Main products: the company operates various types of products with various specifications, including cold bending forming equipment and other mechanical equipment, such as tile pressing machine, machine tool, tapping machine, slotting machine, boring machine, air hammer, gear hobbing machine, nail making machine, marking machine, etc. Wide range of products, welcome to buy.

Похожие товары

Недорогая паяльная машина для инфракрасного нагревателя IC T962A

US $300.00-$350.00

Стальной стержень арматурный сварочный аппарат

US $30000-$32000