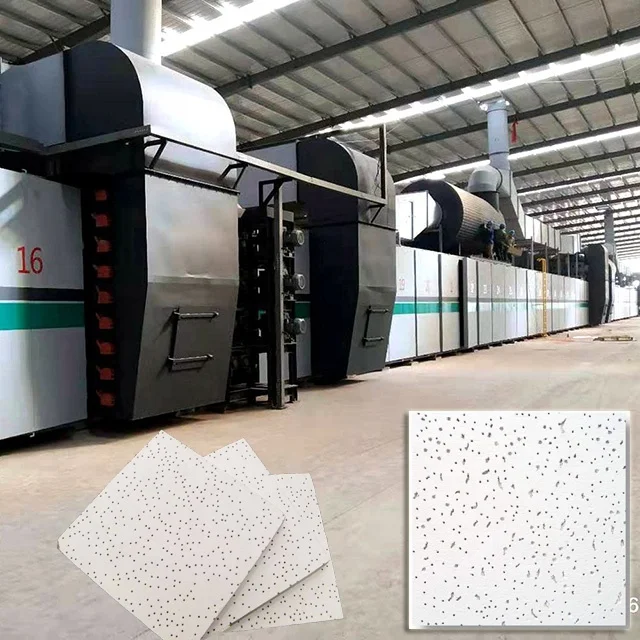

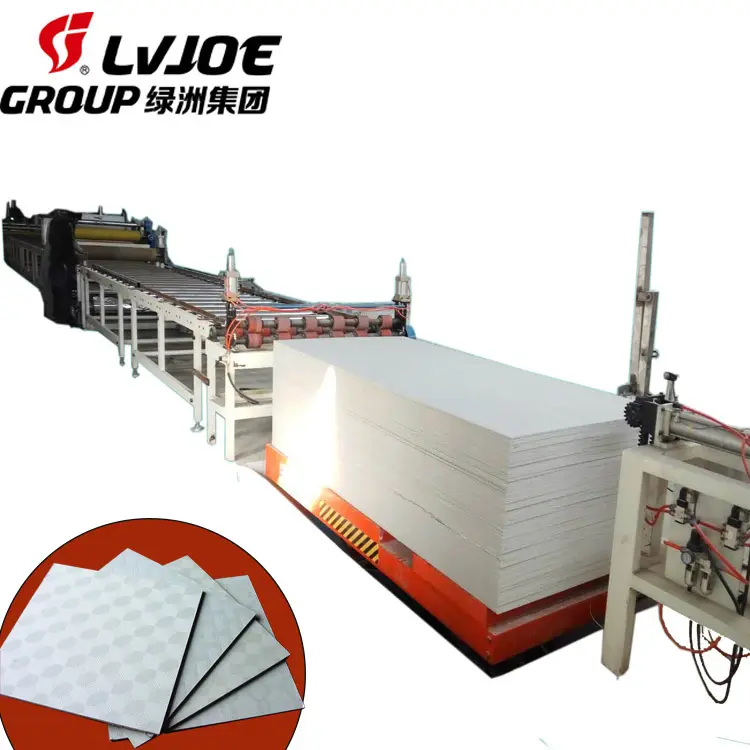

Производственная линия строительных материалов по производству потолочных плит из минерального

- Категория: Building Material Machinery >>>

- Поставщик: Hebei,Greens,Building,Material,Technology,Development,Co.,Ltd.Hebei,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 70572058.47 $* | 74100661.75 $* |

| Aug-17-2025 | 69979015.48 $* | 73477966.81 $* |

| Jul-17-2025 | 58711208.63 $* | 61646768.4 $* |

| Jun-17-2025 | 68792930.82 $* | 72232577.16 $* |

| May-17-2025 | 59897293.97 $* | 62892158.3 $* |

| Apr-17-2025 | 67606845.56 $* | 70987187.3 $* |

| Mar-17-2025 | 67013803.18 $* | 70364493.44 $* |

| Feb-17-2025 | 66420760.8 $* | 69741798.75 $* |

| Jan-17-2025 | 65827718.84 $* | 69119104.87 $* |

Характеристики

Mineral fiber board is a kind of acoustic decorative panel, which is mainly made of mineral fiber and produced by forming, drying, cutting and surface working procedures.

Main Features of final products

1) sound insulation

2) heat insulation

3) fireproofing

4) no-sinking

1.Fourdrinier

Fourdrinier is made up of mesh belt, compression roller, vacuum box and transmission mechanism. After natural dehydrating, vacuum dehydrating and compression dehydrating, wet slurry will form wet slab with a certain moisture content and thickness.

2.Water cutting device

Wet slab will cut into the board with certain length and width, and the transverse cutting is at a certain angle with the long net machine. According to procedure, length cutting.

3. Accelerating conveyor device

After boards with certain length and width forming, they will be sent to accelerating conveyor. Through multi-stage acceleration, the distance between the wet sheet and next is gradually pulled to facilitate the distribution of the wet sheet into the kiln.

4. Distributive bridge

Bridge kiln equipment includes bridge type distributor and feeding machine. The bridge type distributor is a multi-stage double roller conveyor, which is electrically operated and control wet plate of every layer be distributed into the kiln separately. Wet plates were fed into each roller of the feeder.

5.Feeding machine

The roller table of the feeder and the distributor receive the original plate containing water at the same speed, and are converted into slow speeds (ie, kiln speeds) respectively, and the wet plates are sent to the drying kiln for continuous drying.

6.Drying kiln

The system is the core of the whole production line, which effect directly the quality of products and energy consumption of system. There are various adjustment and control mechanism in drying kiln to ensure uniform temperature and airflow in every part, which will ensure drying quality and low consumption.

7.Board releasing device

Distributor receive the board respectively from every layer of roller table at low speed, switching high speed, and compound to a no-overlap layer and send them to the board releasing machine. The machine will transport the original board in order (dry board) to the transfer system.

Name | Consumption |

Waste paper | 0.45Kg/m2 |

Mineral fiber | 2kg/m2 |

Perlite | 1.8Kg/m2 |

Desiccant | 0.1Kg/m2 |

Starch | 0.5kg/m2 |

Back coating | 0.1kg/m2 |

Fiber glass | 0.05kg/m2 |

Electricity consumption | 0.6-0.8Kwh/m2 |

Gas consumption | 0.7m3/m2 |

Water consumption | 5-6kg/m2 |

Hebei Greens Building Material Technology Development Co., Ltd(a branch company of Lvjoe Group) is a large building and construction material machinery manufacturer specializing in researching, designing, manufacturing, project equipment integration and international trade.

Lvjoe Group is original from Hebei LVJOE Machinery Manufacturing Co. Ltd., founded in 1998. With continuing development of Company's business, we established Lvjoe Group in 2016. Greens company as a branch company of LVJOE Group, the main lines of products including gypsum board lamination machine, mineral fiber board production line, fiber cement board production line, MgO board production line, xps foam board machine,gypsum cornice production line, etc.

Factory

Team

Our Team

Warehouse

Our Warehouse

Conference room

Our Conference room

1. Our company has professional installation & debug teams.

We will install and test the production line at the customers' place until the equipment produces the qualified products.

2. We supply the accessories all the year round.

The guarantee time of the equipment is one year.

3. We are responsible for the technical consultation and service all the year around and solve all kinds of technical problems at any time.

4. We can help the customer to do the consignment and the relevant procedure for import and export.

5.If the buyer can not run the machine well then we will send the production engineers to help the buyer to run the machine and we can cooperate for long terms.