Горячая Распродажа Электрический сварочный аппарат с открытой орбитальной трубой для труб из углеродистой стали/нержавеющей стали/из титанового

- Категория: Other Welding Equipment >>>

- Поставщик: Henan,E-Work,Industrial,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.24 $* | 0.30 $* |

| Aug-18-2025 | 0.96 $* | 0.57 $* |

| Jul-18-2025 | 0.59 $* | 0.14 $* |

| Jun-18-2025 | 0.90 $* | 0.5 $* |

| May-18-2025 | 0.14 $* | 0.41 $* |

| Apr-18-2025 | 0.2 $* | 0.10 $* |

| Mar-18-2025 | 0.43 $* | 0.32 $* |

| Feb-18-2025 | 0.6 $* | 0.9 $* |

| Jan-18-2025 | 0.72 $* | 0.80 $* |

Характеристики

Product Description

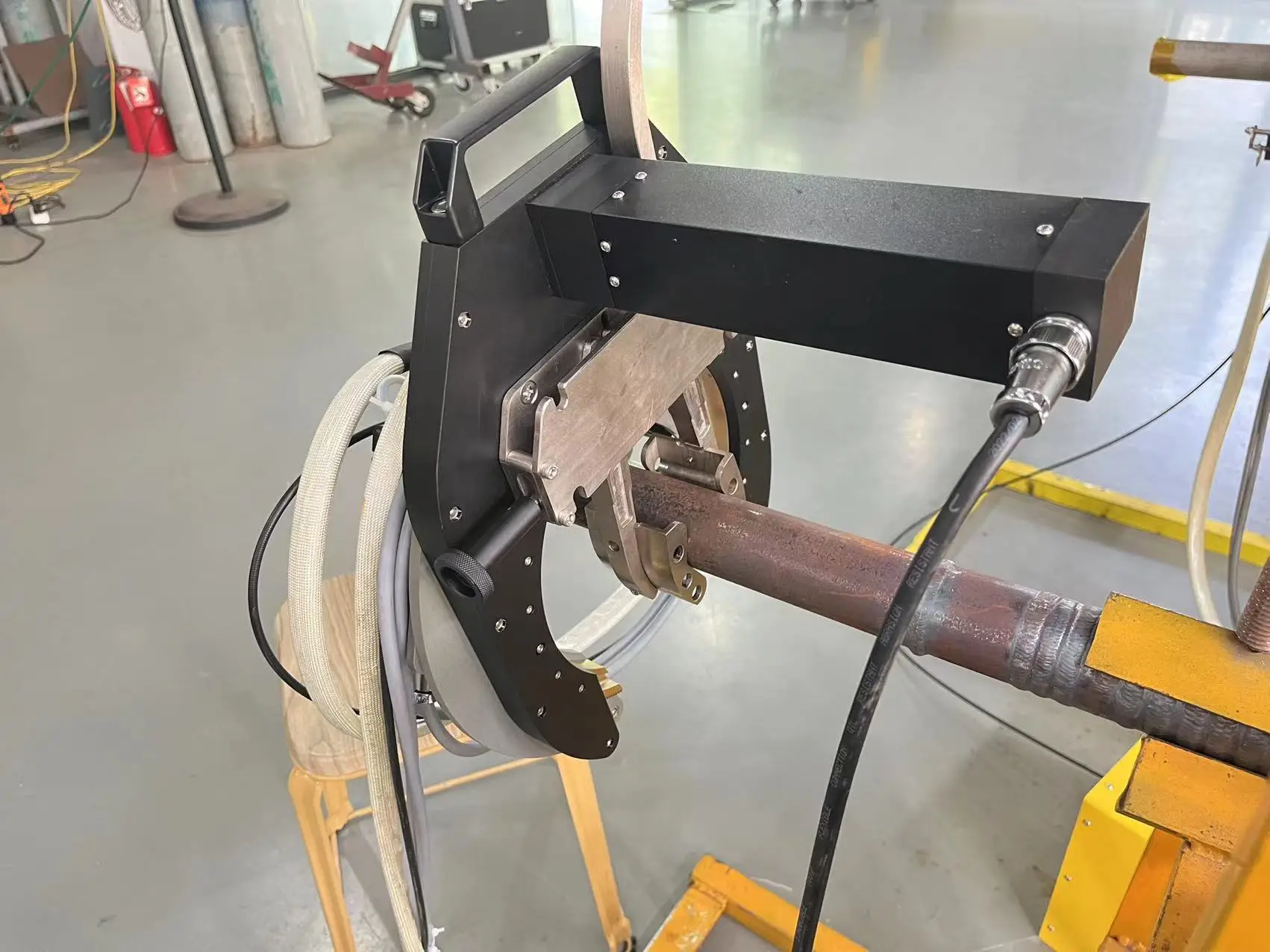

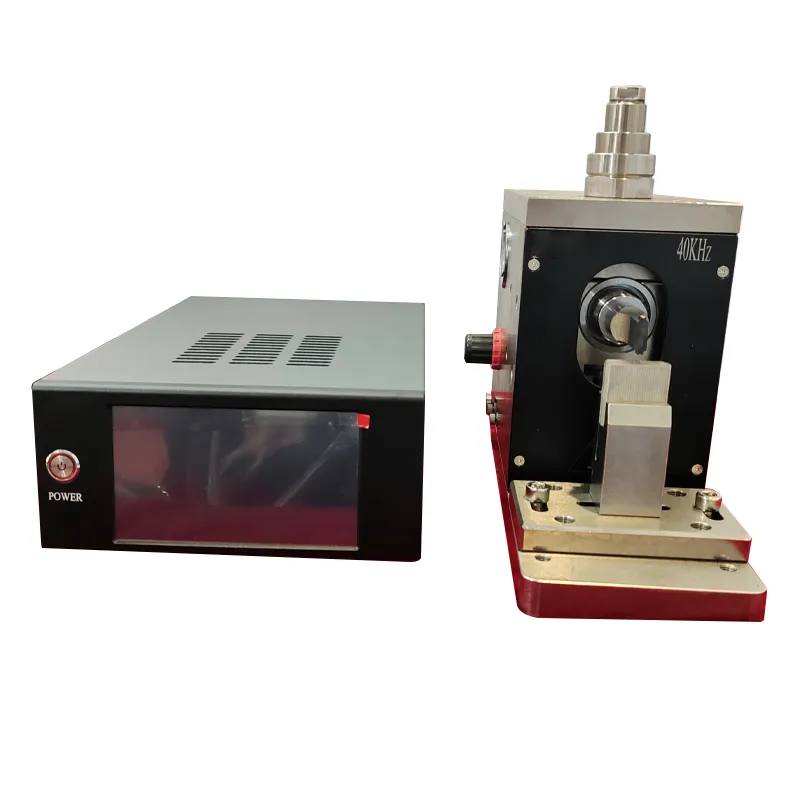

Open Orbital Welding Heads

The orbital tube welding machine is mainly used in electronics, instrumentation, pharmaceutical, food, engineering installation, military and other industries. It's suitable for thin-walled carbon steel, stainless steel, titanium alloy and other materials. The welding tongs adopt a fully enclosed and full-position welding method. It utilizes an advanced full-jacketed integrated water cooling system for high-duty cycles. Coolant channels running through the entire weld head body ensure excellent heat dissipation, allowing the weld head to work continuously even at high welding currents and intensive load.

Open Orbital Welding Heads Our range of open welding heads allows you to make very high-quality welds in minimal space. On these heads, you will find a mechanical tracking system to keep a constant arc height. The torch can tilt to weld at an angle. This type of machine can be used to weld carbon steel tubes. Open heads offer very wide welding possibilities thanks to the inclination of the torch and the addition of filler metal. The clamping range is achieved without the addition of jaws. The tracking system is by roller so as not to scratch the tube. All the parts in contact with the tube are made of stainless steel so as not to contaminate it.

Open Orbital Welding Heads Our range of open welding heads allows you to make very high-quality welds in minimal space. On these heads, you will find a mechanical tracking system to keep a constant arc height. The torch can tilt to weld at an angle. This type of machine can be used to weld carbon steel tubes. Open heads offer very wide welding possibilities thanks to the inclination of the torch and the addition of filler metal. The clamping range is achieved without the addition of jaws. The tracking system is by roller so as not to scratch the tube. All the parts in contact with the tube are made of stainless steel so as not to contaminate it.

Product advantages

1. The equipment adopts a standard modular design, the replacement of spare parts is convenient, and the use cost is low;

2. With the speed measurement function with feedback, the rotation of the welding torch is more accurate and stable, and the angle of the welding seam is monitored in real-time. The rotation speed of the welding torch is accurate and stable, and the perfect welding quality is achieved;

3. With automatic arc length and yaw function, it can meet the welding of pipe fittings of different sizes;

4. The welding torch is cooled by circulating water, with a high-duty cycle, and it can work stably and reliably for a long time without heating;

5. Under the same conditions, different pipe diameters can be welded without readjusting the welding parameters;

6. The welding torch adopts the Haval fixture, which can be adjusted according to the diameter of the pipe fittings so that the welding torch can firmly lock the pipe fittings.

2. With the speed measurement function with feedback, the rotation of the welding torch is more accurate and stable, and the angle of the welding seam is monitored in real-time. The rotation speed of the welding torch is accurate and stable, and the perfect welding quality is achieved;

3. With automatic arc length and yaw function, it can meet the welding of pipe fittings of different sizes;

4. The welding torch is cooled by circulating water, with a high-duty cycle, and it can work stably and reliably for a long time without heating;

5. Under the same conditions, different pipe diameters can be welded without readjusting the welding parameters;

6. The welding torch adopts the Haval fixture, which can be adjusted according to the diameter of the pipe fittings so that the welding torch can firmly lock the pipe fittings.

Specification

Model Parameter | MWG-48 | MWG-90 | MWG-170 | MWG-230 | MWG-325 |

Applicable diameter (mm) | Φ19-38 | Φ20-89 | Φ63-168 | Φ130-230 | Φ159-325 |

Applicable wall thickness (mm) | ≤6 | 1-10 | 2-10 | 2-10 | 2-10 |

Protective gas | Argon | Argon | Argon | Argon | Argon |

Cooling method | circular water- cooling system | circular water- cooling system | circular water- cooling system | circular water- cooling system | circular water- cooling system |

Tungsten diameter (mm) | 2.4 | 2.4 | 2.4 | 2.4 | 2.4, 3.2 |

Weight (KG) | 5 | 6 | 10 | 24 | 36 |

Product Size

Model Size (mm) | MWG-48 | MWG-90 | MWG-170 | MWG-230 | MWG-325 |

A | 59 | 92 | 172 | 235 | 328 |

B | 112 | 165 | 280 | 400 | 500 |

C | 128 | 230 | 340 | 425 | 550 |

D | 360 | 382 | 382 | 437 | 497 |

E | 102 | 135 | 160 | 165 | 181 |

F | 425 | 337 | 453 | 620 | 730 |

Detailed Images

Detailed photos of the Product

Detailed photos of the Welding achievement

Detailed photos of the Packing situation

Company Profile

Henan E-work Industrial Equipment Co., Ltd. is a professional company dedicated to the R&D, production and sales of piping machines and tools related to pipes. In line with the business tenet of "piping solutions expert" and the mission of "making work easy and efficient", we have independently developed and produced a series of products that customers love.

Our product mainly includes closed orbital welding machines, open orbital welding machines, orbital cutting machines, tube end preparation machines and other accessories for pipe processing works. These products are widely used for stainless pipe, steel pipe and alloy pipes.

Our company not only has a professional and skilled workforce but also has established a complete and complete quality management system. We are committed to providing customers with world-class products and look forward to sincere and friendly cooperation with our customers to have a good business together.

Our product mainly includes closed orbital welding machines, open orbital welding machines, orbital cutting machines, tube end preparation machines and other accessories for pipe processing works. These products are widely used for stainless pipe, steel pipe and alloy pipes.

Our company not only has a professional and skilled workforce but also has established a complete and complete quality management system. We are committed to providing customers with world-class products and look forward to sincere and friendly cooperation with our customers to have a good business together.

Похожие товары

Недорогая паяльная машина для инфракрасного нагревателя IC T962A

US $300.00-$350.00

Стальной стержень арматурный сварочный аппарат

US $30000-$32000