Конденсаторное оборудование/металлизированная пленочная конденсаторная Автоматическая производственная линия/машина для

- Категория: Electronics Production Machinery >>>

- Поставщик: Pingxiang,County,Hongjiu,Capacitor,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.64 $* | 0.15 $* |

| Aug-17-2025 | 0.65 $* | 0.10 $* |

| Jul-17-2025 | 0.11 $* | 0.82 $* |

| Jun-17-2025 | 0.33 $* | 0.86 $* |

| May-17-2025 | 0.15 $* | 0.60 $* |

| Apr-17-2025 | 0.49 $* | 0.49 $* |

| Mar-17-2025 | 0.53 $* | 0.78 $* |

| Feb-17-2025 | 0.1 $* | 0.1 $* |

| Jan-17-2025 | 0.11 $* | 0.90 $* |

Характеристики

Product Description

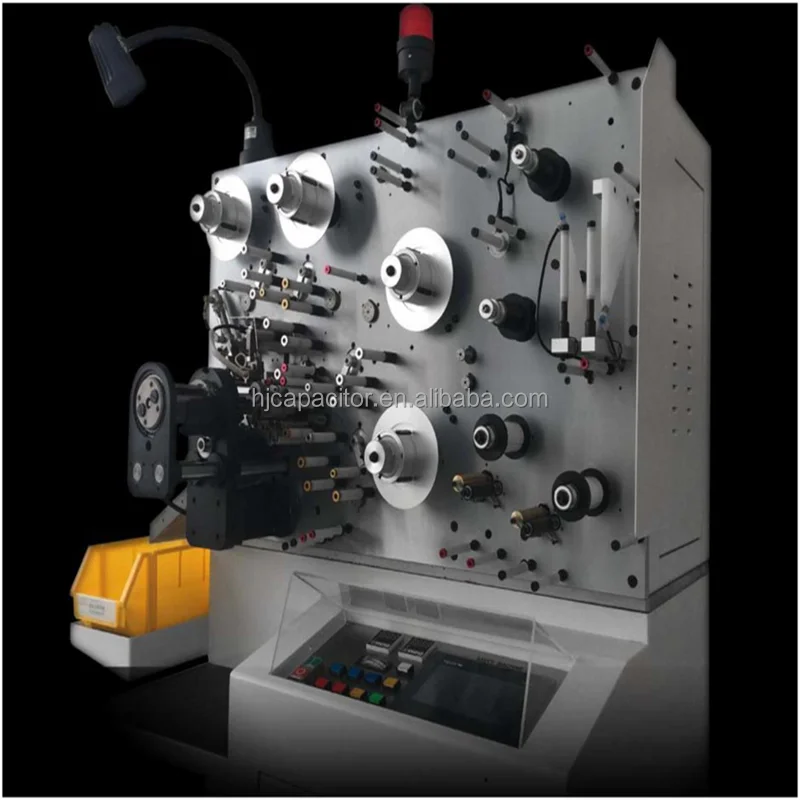

1.High speed winding

* Adopting Schneider 238PLC and 7”touching screen, which substantially increases the computing capability of CPU in comparison

with the previous generation of machine.

* Winding is based on the linear speed control. The variation of film speed per unit time may maintain the same. This mode allows

higher winding speed and better smoothness of winding speed.

* Software supports to winding the last turn in the period of head rotation. Means 0.2 sec. time can be saved.

* Actual output is 2,400pcs/hour for the capacitor 100 turns.

2. Saving more material than the previous generation

Through software the length of initial burn off can be adjusted instead of fixed length as the previous generation.

3. Data saving function

More than 200 winding receipt may be saved. The function may easy machine management and operation.

4. AC servo for main winding

AC servo motor for main winding, precise positioning, fast response.

5. Easy to operate

* Based on the data of material and desire capacitance, Machine control system will automatically calculate the requested winding

turns, tension, pressing force, and final overall dimensions.

* Administrator may limit the max, winding speed and acceleration.

6.More Configuration possibility

* Series A/G are available for the winding of small size capacitor. As G Type machine has small footprint and compact structure,

it is the best choice to wind miniature capacitor in double winding mode.

* Electrical tension control is available for some models of machine.

* For having more precise winding and better film alignment, Air guide is available for some models of machine.

* As optional, Burn off voltage can be 0 – 50 V.

* Adopting Schneider 238PLC and 7”touching screen, which substantially increases the computing capability of CPU in comparison

with the previous generation of machine.

* Winding is based on the linear speed control. The variation of film speed per unit time may maintain the same. This mode allows

higher winding speed and better smoothness of winding speed.

* Software supports to winding the last turn in the period of head rotation. Means 0.2 sec. time can be saved.

* Actual output is 2,400pcs/hour for the capacitor 100 turns.

2. Saving more material than the previous generation

Through software the length of initial burn off can be adjusted instead of fixed length as the previous generation.

3. Data saving function

More than 200 winding receipt may be saved. The function may easy machine management and operation.

4. AC servo for main winding

AC servo motor for main winding, precise positioning, fast response.

5. Easy to operate

* Based on the data of material and desire capacitance, Machine control system will automatically calculate the requested winding

turns, tension, pressing force, and final overall dimensions.

* Administrator may limit the max, winding speed and acceleration.

6.More Configuration possibility

* Series A/G are available for the winding of small size capacitor. As G Type machine has small footprint and compact structure,

it is the best choice to wind miniature capacitor in double winding mode.

* Electrical tension control is available for some models of machine.

* For having more precise winding and better film alignment, Air guide is available for some models of machine.

* As optional, Burn off voltage can be 0 – 50 V.

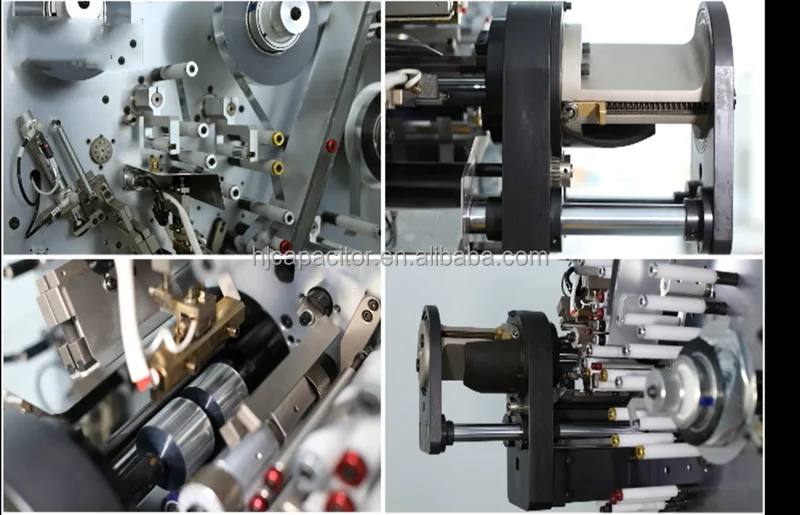

Product Photo

Company Profile

If you are interested in these machines, please feel free to contact me:

Process Flow

Slitting

Winding

Metal Spraying

Material Drying

Semi-Product Testing

Assembling

Duradility Testing

Finisbed Product Storage

Our Advantages

Choose Hongjiu to create brilliance.

I'm not the biggest, but I must be the best. 100% of your tasks.

I'm not the biggest, but I must be the best. 100% of your tasks.

Exhibition

Packing & Delivery

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes,we can provide good after-sale and fast delivery.

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes,we can provide good after-sale and fast delivery.