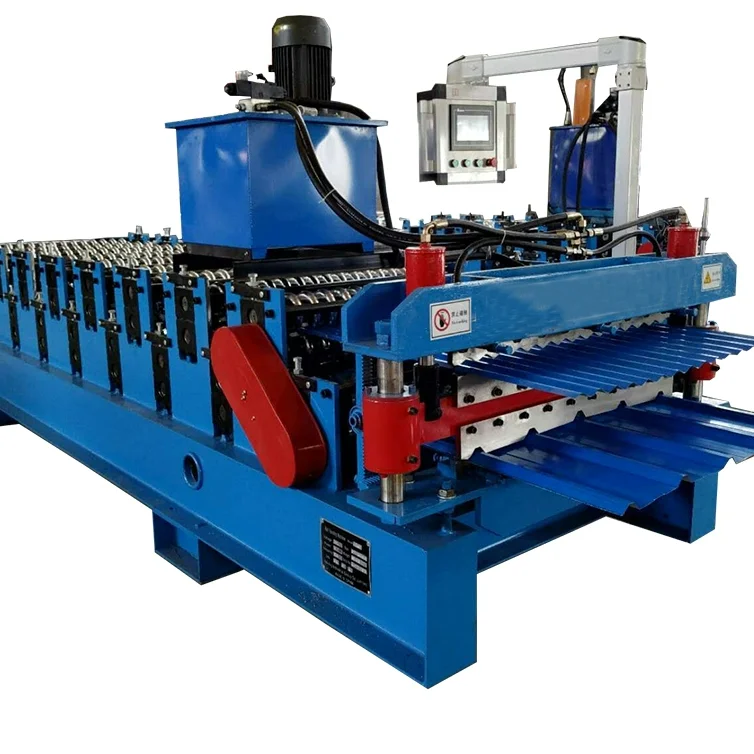

Машина для изготовления гофрированной и трапециевидной кровельной плитки двухслойная машина металлических

- Категория: Building Material Machinery >>>

- Поставщик: Henan,Austing,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 10234.2 $* | 10746.4 $* |

| Aug-18-2025 | 10148.20 $* | 10655.73 $* |

| Jul-18-2025 | 8514.53 $* | 8940.37 $* |

| Jun-18-2025 | 9976.40 $* | 10475.13 $* |

| May-18-2025 | 8686.9 $* | 9120.89 $* |

| Apr-18-2025 | 9804.26 $* | 10294.14 $* |

| Mar-18-2025 | 9718.31 $* | 10204.49 $* |

| Feb-18-2025 | 9632.31 $* | 10114.26 $* |

| Jan-18-2025 | 9546.53 $* | 10023.95 $* |

Характеристики

Products Description

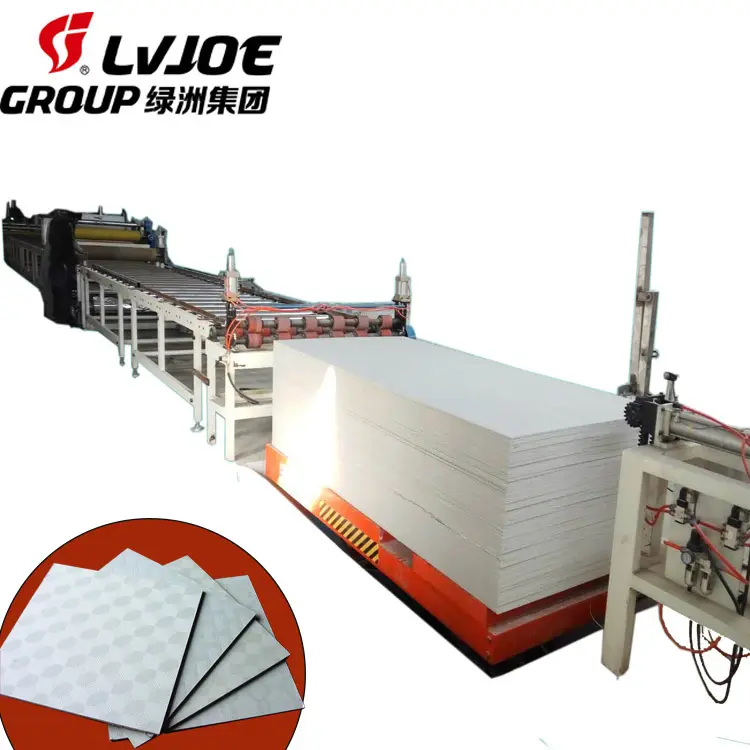

The production size we can design the machine all as customize,customer just show us the profile drawing material thickness width,Different roof panel forming machines can produce different shapes of steel roof wall sheets according to the client’s profile drawings and requirements. The steel roof, wall sheets are new building materials with various thickness and colors.

The main products are 840 color steel pressing tile forming machine, 860 color steel pressing tile forming machine, 900 color steel pressing tile forming machine, 1155 color steel pressing tile forming machine, 840/900 double-layer color steel pressing tile forming machine, 860/910 Double-layer color steel tile forming machine, double-layer tile forming machine, water-stopping machine, wall panel forming machine, roofing machine forming machine, angle-pressing tile forming machine, C-shaped steel forming machine,Z-shaped steel forming machine, glazed tile forming Machine, floor board forming tile machine, adjusting guardrail forming machine, automatic hydraulic automatic unwinding machine, leveling machine, etc.

Working Process

Specification

Main power: | 11KW Siemens motor made in China |

Machine Structure: | Separate stands tower,chromed on the surface of the stands ( see the picture) |

Feeding form: | Side hand wheel adjustment manually |

Roll forming stations: | 20 stations for upper layer |

Way of drive: | single row 1.0 inch chain drive |

Diameter of shaft: | ¢75mm |

Material of shaft: | 40Cr refining (HB220-260) |

Cutting system: | hydraulic flying shear( non-stop cutting)controlled by the servo motor |

Roll forming stations: | 20 stations for upper layer |

Way of drive: | single row 1.0 inch chain drive |

Diameter of shaft: | ¢75mm |

Material of shaft: | 40Cr refining (HB220-260) |

Cutting system: | hydraulic flying shear( non-stop cutting)controlled by the servo motor |

Product Details

Packaging & Shipping

Why Choose Us

Company Profile

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you .

6: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as Roll Forming Machine, CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on .

3: Where is our factory located? How can I visit there?

A : Our factory is located in Zhengzhou City , Henan Province, China. You are warmly welcomed to visit us.

4. What is your trade terms?

A : EXW, FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ; Irrevocable LC at sight

A: We specialized in all kinds of machines ,such as Roll Forming Machine, CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on .

3: Where is our factory located? How can I visit there?

A : Our factory is located in Zhengzhou City , Henan Province, China. You are warmly welcomed to visit us.

4. What is your trade terms?

A : EXW, FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ; Irrevocable LC at sight

6: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )