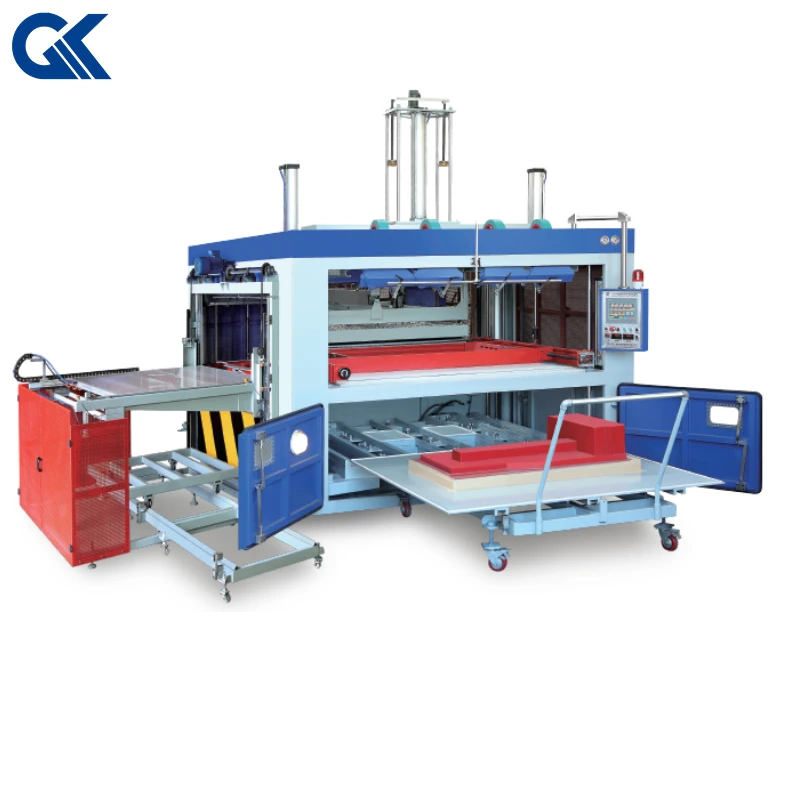

Автоматическая вакуумная блистерная машина для формовки акриловой ванны Термоформовочная

- Категория: Plastic Vacuum Forming Machines >>>

- Поставщик: Ruian,Gaoke,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.12 $* | 0.53 $* |

| Aug-19-2025 | 0.64 $* | 0.1 $* |

| Jul-19-2025 | 0.99 $* | 0.45 $* |

| Jun-19-2025 | 0.28 $* | 0.0 $* |

| May-19-2025 | 0.39 $* | 0.66 $* |

| Apr-19-2025 | 0.89 $* | 0.48 $* |

| Mar-19-2025 | 0.0 $* | 0.40 $* |

| Feb-19-2025 | 0.30 $* | 0.78 $* |

| Jan-19-2025 | 0.57 $* | 0.38 $* |

Характеристики

Product Description

* Working Cycle:-

Manual feeding → clamping → moving the oven to the forming area → heating → moving the oven back to the heating area → lower the oven up → anti-sagging → foaming → blister forming → cooling → demolding → lower mold reset → manually take out the finished product.

Manual feeding → clamping → moving the oven to the forming area → heating → moving the oven back to the heating area → lower the oven up → anti-sagging → foaming → blister forming → cooling → demolding → lower mold reset → manually take out the finished product.

Basic units:-

1. Heater adopts ceramic heating bricks.

2. Heater drives by cylinder to insure heater work fleetly and placidly.

3. The equipment with the safety and protection equipment.

4. Clamp unit, controlled by pneumatic solenoid valve. Clamping unit

assembled synchronous unit for material pressing. This machine adopts

iron clamp bracket, which can bear high temperature, avoid the clamp

bracket metamorphosed and adjust width and length arbitrarily.

5. Complete vacuum system includes vacuum room, vacuum pump,

vacuum storage gas pot, vacuum pipeline, adjustable air cleaner device

and vacuum controlling unit.

6. Cooling system assemble air blower and spray gun. The spray gun

could be adjusted according to different products making.

7. Automatic degassing before mold ejecting.

2 /5RUIAN GAOKE Machinery Co., Ltd

Tel/whatsapp:+86 17326787326 Email:sales@gaokemachine.com

8. This machine controlled by PLC, touch screen control system and

display and controls the operation of equipment. Operation panel

installed at the left of front side and free to turn.

9. The front door is movable door; it’s convenient for changing mould.

Excellence of equipment:-

1. Heater (controlled separately)

2. Heater separately: Set different temperature according material

forming demand to insure product quality. Adjusted the voltage of

heater by AC voltage meter which can insures the heater temperature

steady and save power.

1. Change the heater units fleetly. And it is economical for maintain

because it only need change part units.

2. Controlling the heater unit separately can short the heating time and

economize energy and improve product quality and reduce cost.

3. Adjustable frame: The side size clamping is 20--50mm which can

economize the material. And the total of economized material is a

considerable amount.

4. Sheet sag control device: Prevented sheet sag after heating by

pressure support system, and assembled photoelectric switch.

5. Machine with double heaters and drove by pneumatic pressure, it is

3 /5RUIAN GAOKE Machinery Co., Ltd

Tel/whatsapp:+86 17326787326 Email:sales@gaokemachine.com

4 /5

suitable thermoforming ABS, PMMA/ABS, PE, PVC, PET, PS, PP sheet

which thickness within 10mm or more (depend on the material).

6. Max. Mold height can up to 650mm.

1. Heater adopts ceramic heating bricks.

2. Heater drives by cylinder to insure heater work fleetly and placidly.

3. The equipment with the safety and protection equipment.

4. Clamp unit, controlled by pneumatic solenoid valve. Clamping unit

assembled synchronous unit for material pressing. This machine adopts

iron clamp bracket, which can bear high temperature, avoid the clamp

bracket metamorphosed and adjust width and length arbitrarily.

5. Complete vacuum system includes vacuum room, vacuum pump,

vacuum storage gas pot, vacuum pipeline, adjustable air cleaner device

and vacuum controlling unit.

6. Cooling system assemble air blower and spray gun. The spray gun

could be adjusted according to different products making.

7. Automatic degassing before mold ejecting.

2 /5RUIAN GAOKE Machinery Co., Ltd

Tel/whatsapp:+86 17326787326 Email:sales@gaokemachine.com

8. This machine controlled by PLC, touch screen control system and

display and controls the operation of equipment. Operation panel

installed at the left of front side and free to turn.

9. The front door is movable door; it’s convenient for changing mould.

Excellence of equipment:-

1. Heater (controlled separately)

2. Heater separately: Set different temperature according material

forming demand to insure product quality. Adjusted the voltage of

heater by AC voltage meter which can insures the heater temperature

steady and save power.

1. Change the heater units fleetly. And it is economical for maintain

because it only need change part units.

2. Controlling the heater unit separately can short the heating time and

economize energy and improve product quality and reduce cost.

3. Adjustable frame: The side size clamping is 20--50mm which can

economize the material. And the total of economized material is a

considerable amount.

4. Sheet sag control device: Prevented sheet sag after heating by

pressure support system, and assembled photoelectric switch.

5. Machine with double heaters and drove by pneumatic pressure, it is

3 /5RUIAN GAOKE Machinery Co., Ltd

Tel/whatsapp:+86 17326787326 Email:sales@gaokemachine.com

4 /5

suitable thermoforming ABS, PMMA/ABS, PE, PVC, PET, PS, PP sheet

which thickness within 10mm or more (depend on the material).

6. Max. Mold height can up to 650mm.

Specification

Main Technical Parameters:-

Forming area :2500*1500mm

Forming height :350mm

Production speed: 8-60Cycles/h

Electric furnace power consumption :181kw

Vacuum pump motor power consumption :3Kw

Vacuum pump capacity: 100m3/h

Voltage :380/220V 50HZ

Dimensions:3100*4700*3500mm

Weight :13500kg

Forming area :2500*1500mm

Forming height :350mm

Production speed: 8-60Cycles/h

Electric furnace power consumption :181kw

Vacuum pump motor power consumption :3Kw

Vacuum pump capacity: 100m3/h

Voltage :380/220V 50HZ

Dimensions:3100*4700*3500mm

Weight :13500kg

Packing&Shipment

FAQ

1. What is the machine warranty?

one year.

2. Does your machine with CE certificate?

Yes, it does

3. What is the production time while placing order?

About 30 days

4. What is the delivery time?

Within 30 days after get the payment.

5. Can your company handle shipping for customers?

Yes.(Please provide us your requested seaport and we can check the shipping charge and arrange shipping for your order)

6. Does the packing strong?

Yes, of course! All of our export packing is with strong wooden pallets, all are confirmed to export packing standard.

7. How about after-sales service process?

When your machine has problem, contact your sales and we will solve your problem as soon as possible.

8. Are you manufacturer?

Yes, we are manufacturer with 10-year experience and profession.

9. Do you have stock product to sell?

Actually our machine need 20-30 days to manufacture, and there are many orders from China and foreign countries, so we need

custom one for you, and your order will be highly attention to manufacture.

10. Do you inspect the finished products?

Yes, we have QC department, they will inspection the machine before shipping to ensure there is nothing problem of the machine

.

11. What's the payment term?

T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

We are professional manufacturer since 2005. We believe our products will provide

you with great business benefits and advantage.

Our faith:

1) Society's Avail First

2) Client's Avail First

3) Employee's Avail First

4) Enterprise's Avail Second

one year.

2. Does your machine with CE certificate?

Yes, it does

3. What is the production time while placing order?

About 30 days

4. What is the delivery time?

Within 30 days after get the payment.

5. Can your company handle shipping for customers?

Yes.(Please provide us your requested seaport and we can check the shipping charge and arrange shipping for your order)

6. Does the packing strong?

Yes, of course! All of our export packing is with strong wooden pallets, all are confirmed to export packing standard.

7. How about after-sales service process?

When your machine has problem, contact your sales and we will solve your problem as soon as possible.

8. Are you manufacturer?

Yes, we are manufacturer with 10-year experience and profession.

9. Do you have stock product to sell?

Actually our machine need 20-30 days to manufacture, and there are many orders from China and foreign countries, so we need

custom one for you, and your order will be highly attention to manufacture.

10. Do you inspect the finished products?

Yes, we have QC department, they will inspection the machine before shipping to ensure there is nothing problem of the machine

.

11. What's the payment term?

T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

We are professional manufacturer since 2005. We believe our products will provide

you with great business benefits and advantage.

Our faith:

1) Society's Avail First

2) Client's Avail First

3) Employee's Avail First

4) Enterprise's Avail Second