Полностью Автоматическая установка для производства Цементных

- Категория: Building Material Machinery >>>

- Поставщик: Yurui,(shandong),Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 114556768.99 $* | 120284606.24 $* |

| Aug-18-2025 | 113594107.89 $* | 119273812.51 $* |

| Jul-18-2025 | 95303530.12 $* | 100068707.43 $* |

| Jun-18-2025 | 111668783.16 $* | 117252222.83 $* |

| May-18-2025 | 97228854.71 $* | 102090297.72 $* |

| Apr-18-2025 | 109743459.15 $* | 115230632.63 $* |

| Mar-18-2025 | 108780797.37 $* | 114219837.40 $* |

| Feb-18-2025 | 107818135.28 $* | 113209042.45 $* |

| Jan-18-2025 | 106855473.61 $* | 112198247.68 $* |

Характеристики

We have developed the latest equipment to produce not only MGO board but also FIBER CEMENT board and Paperless GYPSUM board, with just a few minor changes. It means that you could produce these 3 different boards with the one production line.

Aren't you interested? Pls contact us to get more information.

Aren't you interested? Pls contact us to get more information.

Company Introduction

YURUI Machinery - Professional MgO Board Machine Solution Provider

Yurui (Shandong) Machinery Co., Ltd mainly engaged in the manufacturing and exporting of the construction material and construction material production line.

Product choosing is one of the most important milestones for the company’s development. Magnesium oxide board is the most potential product in the construction material field. Fireproof; Moisture-proof; Environmental friendly makes it an irreplaceable product in the construction material field. Its uniqueness enhances a lot of competitiveness over other construction materials. Magnesium oxide board machine gives the possibility for those customers who would like to develop MgO board in the more deeply, long-term and keep developing the new products, building the brand.

Our position is helping customers produce customized products; only high-valued products could help customers stronger. For the production line project, we regard this process as building dreams. From an empty land to building the steel frames; to designing the whole layout to the final factory running. Each project represents each customer's dream. We know exactly how important to be a dream builder.

Product choosing is one of the most important milestones for the company’s development. Magnesium oxide board is the most potential product in the construction material field. Fireproof; Moisture-proof; Environmental friendly makes it an irreplaceable product in the construction material field. Its uniqueness enhances a lot of competitiveness over other construction materials. Magnesium oxide board machine gives the possibility for those customers who would like to develop MgO board in the more deeply, long-term and keep developing the new products, building the brand.

Our position is helping customers produce customized products; only high-valued products could help customers stronger. For the production line project, we regard this process as building dreams. From an empty land to building the steel frames; to designing the whole layout to the final factory running. Each project represents each customer's dream. We know exactly how important to be a dream builder.

Our Factory

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Project Overview

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

1 | Finished Product | Standard board and Premium Sanding MgO board |

2 | Product Specification | (2440-3050)*(1220)*(3-20)mm |

3 | Designed Capacity | 250-300 PCS /hour |

4 | Workshop Requirements | Building area: 10,000 square meters (including raw material area, production area, curing area, finished product area). Plant height ≥ 6 meters, Mixing area height ≥ 9.5 meters |

5 | Design transformer installed capacity | 630KVA |

6 | Designed production water consumption | 40 Ton/ Shift |

7 | Design compressed air consumption | 8 cbm/min |

8 | Natural gas consumption | 400 cbm/day(based on 0°C, winter season) |

9 | Design and production labours | around 25/shift(Aslo should based on to production process requirements) |

Main Equipment Introduction

Mixing System

This platform includes the metering system, a mixing system that could feed, meter, mixing the raw materials based on the formula.

High-quality steel and welding methods provide a good platform.

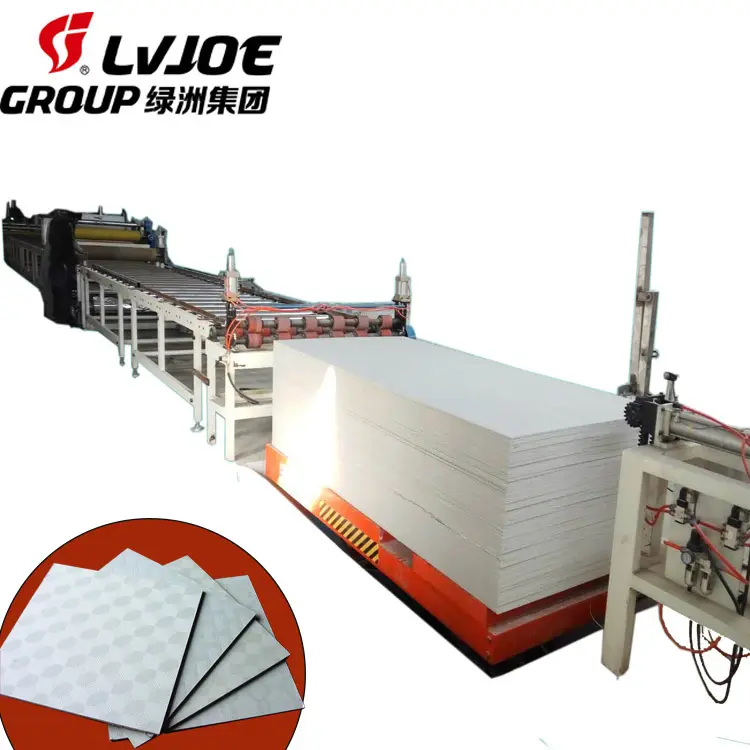

MgO Board Forming Line

Built-in adjustable program for automatically controlling the mould feeding, gluing, and forming processes. It combines the automatic control technology, sensor technology, computer management technology in the integration of mechanical and electrical integration system, having advantages such as high controlling precision, etc.

Demolding Line

When we stack the boards, we need to stack with face to face. because if the face to backside, it is easy to scratch the face side. The automatic flip machine makes this part automatic, no need workers do it.

Finished Products

Magnesium oxide board - New generation fireproof building material

MGO Board is a type of construction board based on magnesium Sulfate and MgO cement. It has become more widely used as sheeting material in the construction industry. GO Board is highly durable, incombustible (fire rating class: A1), lightweight, energy-efficient, sound insulating, impact-resistant, non-toxic, mold and asbestos-free, 100% recyclable, easy to handle, and quick to install.

Because of the unique fireproof advantages, it has become a good substitute to replace traditional boards, especially in some countries, for large buildings like office spaces; hospitals, and other public places.

In addition to fire resistance, the MgO board’s other features are far higher than other boards, such as strength, waterproofing, and environmental protection.

In recent years, environmental protection has been paid more and more attention by governments. The green and environment-friendly MgO board has also become one of his biggest selling points since the level of CO2 is 5%. For the plasterboard, it is 95%.

So MgO board is becoming more and more popular in the world.

Because of the unique fireproof advantages, it has become a good substitute to replace traditional boards, especially in some countries, for large buildings like office spaces; hospitals, and other public places.

In addition to fire resistance, the MgO board’s other features are far higher than other boards, such as strength, waterproofing, and environmental protection.

In recent years, environmental protection has been paid more and more attention by governments. The green and environment-friendly MgO board has also become one of his biggest selling points since the level of CO2 is 5%. For the plasterboard, it is 95%.

So MgO board is becoming more and more popular in the world.

Packing & Shipment

Well delivery and protection

We will design loading qty many times, so as to save your sea freight.

* Firstly use plastic film to wrap and cover the machine;

* Then pack small parts in plywood box.

* Marked with required label or shipping mark.

* Use steel wire rope to fix in the container, so as to avoid damage because of moving.

* Firstly use plastic film to wrap and cover the machine;

* Then pack small parts in plywood box.

* Marked with required label or shipping mark.

* Use steel wire rope to fix in the container, so as to avoid damage because of moving.

Project Show

Brazil project

Special designed production line, could produce MgO board and also the fiber cement board in this line. Customer builds a successful project and brand in his local market.

FAQ

Q: How long is the warranty of your equipment?

A: 1 year.

Q: Do you supply spare parts?

A: Excellent easy broken parts support for buyers. Easy broken parts guarantee for one year.

Q: How will you provide installation & commissioning?

A: We could send 2~8 persons (adjustable according to the degree of automatic) to customer place for on-site

installation.Engineers team will go with your project.

Q:How long time for the installation and commissioning?

A: depend on configuration normally only need 15-25 days. Including workers training.

Q: Will you provide training?

A: The training is free of charge , and our engineer will be on duty to train your worker.

Warmly welcome you contact me for your questions.

Q: Do you supply spare parts?

A: Excellent easy broken parts support for buyers. Easy broken parts guarantee for one year.

Q: How will you provide installation & commissioning?

A: We could send 2~8 persons (adjustable according to the degree of automatic) to customer place for on-site

installation.Engineers team will go with your project.

Q:How long time for the installation and commissioning?

A: depend on configuration normally only need 15-25 days. Including workers training.

Q: Will you provide training?

A: The training is free of charge , and our engineer will be on duty to train your worker.

Warmly welcome you contact me for your questions.