Зерна Упаковка Риса сахара упаковочная машина 15 кг полностью автоматическая для

- Категория: >>>

- Поставщик: Durzerd,Packaging,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 26180.17 $* | 27489.48 $* |

| Aug-18-2025 | 25960.81 $* | 27258.25 $* |

| Jul-18-2025 | 21780.34 $* | 22869.34 $* |

| Jun-18-2025 | 25520.32 $* | 26796.44 $* |

| May-18-2025 | 22220.65 $* | 23331.72 $* |

| Apr-18-2025 | 25080.8 $* | 26334.50 $* |

| Mar-18-2025 | 24860.40 $* | 26103.19 $* |

| Feb-18-2025 | 24640.26 $* | 25872.41 $* |

| Jan-18-2025 | 24420.5 $* | 25641.7 $* |

Характеристики

Model | ZD200/400/600 |

Packable Products | granules/ powders/flake particles |

Bag Type | PE bags/ aluminum foil bags/ woven bags/ paper bags/ paper-plastic composite bags etc. |

Roll Film | Diameter of roll film≤1500mm, Inner tube of roll film: 150mm (6 inches) |

Empty Bag Size | L(500-750mm), W(320-420mm) |

Packaging Weight | 20-50 kg/bag |

Packaging Speed | 300~600 bags/h |

Power | 3 kW |

Air Consumption | 200 NL/min |

Equipment Size (L*W*H) | 2904 * 2920 * 2190 |

Open Mouth Bagging Machine

The open mouth bagging systems are designed for bagging free-flowing materials into open-mouth bags for applications between 5 and 50kg per bag. The systems are ideal for bagging flakes and granules from the Food, Feed, Pet Food, Chemicals, and Minerals industries.

The open mouth bagging equipment features modular designs in three versions: compact open-mouth bagging system (ZD-200 SERIES upto 200 bags per hour / ZD-400 SERIES up to 400 bags per hour), high-speed open-mouth bagging system (ZD-600 SERIES, up to 600 bags per hour) and high-speed open-mouth bagging system for PE bags (ZD-600 FS SERIES, up to 600 bags per hour). Units can be supplied with either our gross or net weighing systems for optimum system performance.

The open mouth bagging equipment features modular designs in three versions: compact open-mouth bagging system (ZD-200 SERIES upto 200 bags per hour / ZD-400 SERIES up to 400 bags per hour), high-speed open-mouth bagging system (ZD-600 SERIES, up to 600 bags per hour) and high-speed open-mouth bagging system for PE bags (ZD-600 FS SERIES, up to 600 bags per hour). Units can be supplied with either our gross or net weighing systems for optimum system performance.

* Automatic adjustments for quick product and bag changeovers

* Total bag top control

* Optimised dust control

* PLC controlled with user-friendly human machine interfaces (HMI)

* Easy clean and easy maintenance configurations

* Compact design ideal for restricted packaging rooms

* Fully integrated gross or nett weighing system

* Total bag top control

* Optimised dust control

* PLC controlled with user-friendly human machine interfaces (HMI)

* Easy clean and easy maintenance configurations

* Compact design ideal for restricted packaging rooms

* Fully integrated gross or nett weighing system

1. Pre-place Empty Bags

Place 2~3 stacks of empty bags at the same time to provide bags for the packaging machine.

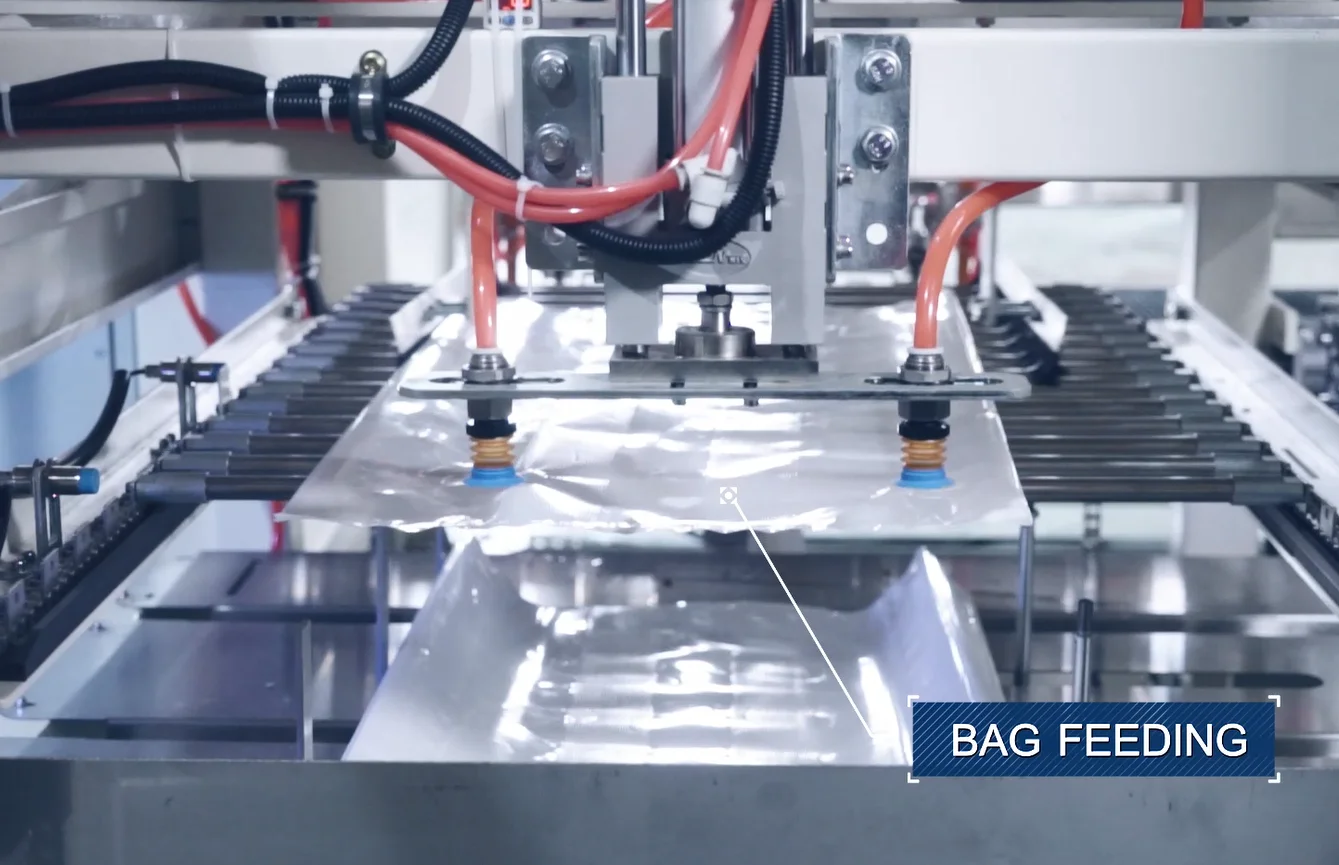

2.Take an Empty bag

The bag sucking mechanism sucks the bottom of the bag with negative pressure, while the roller-up type bag transmission structure flattens the bag mouth and transmits it to the bag opening station.

3.Open Empty bag

The bag opening mechanism simultaneously sucks the positive and negative sides of the bag mouth with negative pressure. The negative pressure sucks the bag mouth and lifts it, and then the "insert knives" structure located on both sides of the material discharge port is inserted into the bag mouth by shaft rotation and spread to both sides.

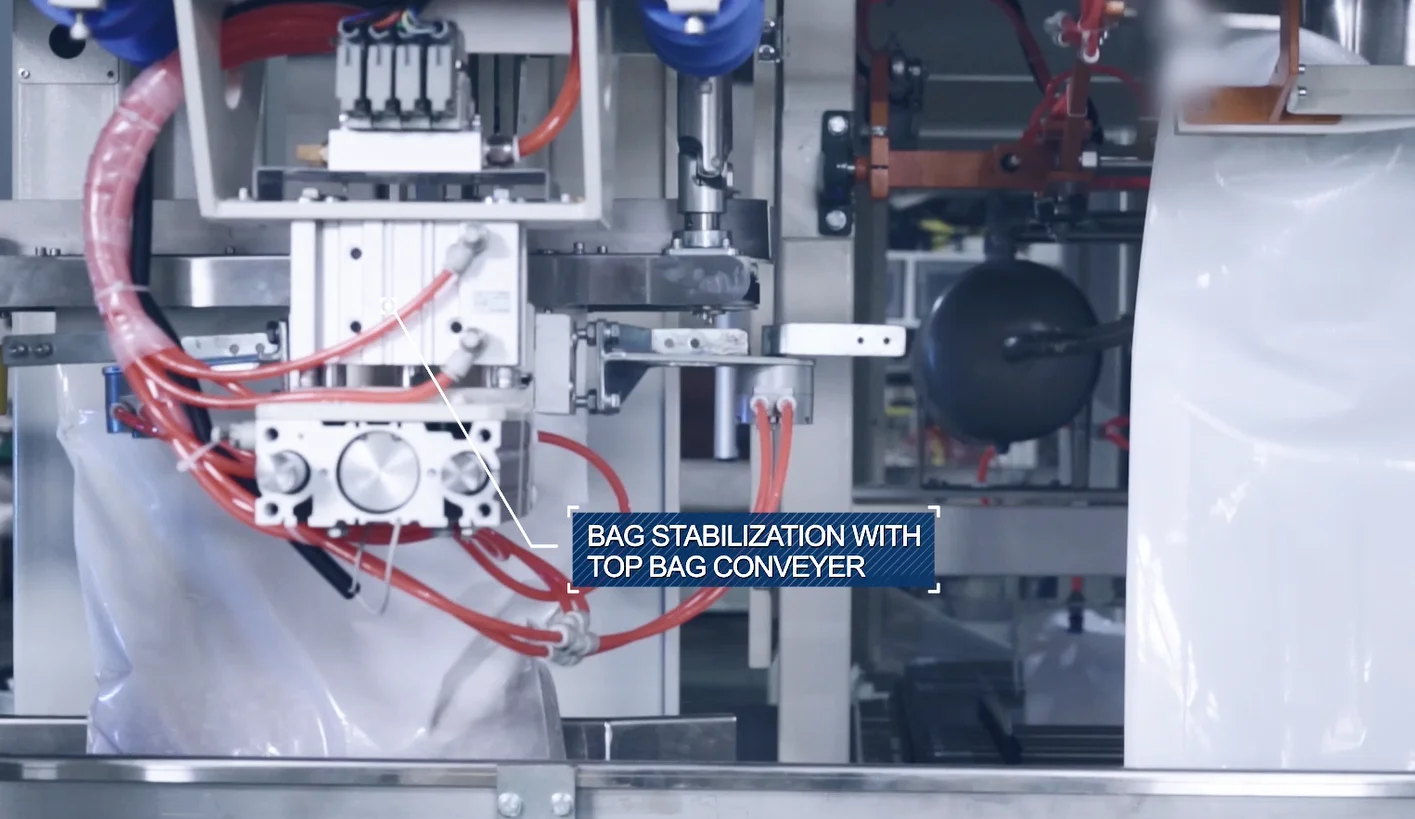

4.Supply Empty bag

Transfer the empty bag to the bag clamping mechanism by lifting up the knife arm to complete the bag supplying operation. The bag clamping mechanism clamps both sides of the bag to prevent dust from overflowing.

5.Material Filling

The bag clamping detection device ensures the reliability of the bag supplying. After the detection is completed, the PLC will give a signal to the automatic weighing unit, then the material in the weighing unit will be discharged into the packaging bag.

6.Holding bag and Heat Sealing

After the material filling is completed, the bag mouth is clamped horizontally through the bag-holding conveying mechanism, then the bag is horizontally conveyed to the guide entry mechanism, and the bag is conveyed to the heat sealing station for automatic heat sealing.

Q1: Are you a factory or a trading company?

A1:We are the factory with manufacturing and self-supporting import and export rights for more than 25 years.

Q2: How to choose suitable packaging machine?

A2:Need to provide your material pictures and requirements, such as packaging speed, packaging weight, bag type and bag size.

Q3: How about the payment way?

A3:Payment can be T/T, L/C etc. we can provide FOB, CNF, CIF term by sea.

Q4: How to ensure the quality of the machine?

A4:We usually delivery the machine after successful inspection in our factory. We have our own quality control department,before the delivery we have to running the machine for three days without problem. You can send us your materials and we will make video as long as you want. Or you can arrange a third-party inspection agency.

Q5: How to install the equipment?

A5:We will provide manuals and detailed videos to help customer install machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room expenses and a daily subsidy of 150 US dollars.

A1:We are the factory with manufacturing and self-supporting import and export rights for more than 25 years.

Q2: How to choose suitable packaging machine?

A2:Need to provide your material pictures and requirements, such as packaging speed, packaging weight, bag type and bag size.

Q3: How about the payment way?

A3:Payment can be T/T, L/C etc. we can provide FOB, CNF, CIF term by sea.

Q4: How to ensure the quality of the machine?

A4:We usually delivery the machine after successful inspection in our factory. We have our own quality control department,before the delivery we have to running the machine for three days without problem. You can send us your materials and we will make video as long as you want. Or you can arrange a third-party inspection agency.

Q5: How to install the equipment?

A5:We will provide manuals and detailed videos to help customer install machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room expenses and a daily subsidy of 150 US dollars.