Высокопроизводительный сварочный аппарат для окружности газового цилиндра сжиженного нефтяного газа сварочное

- Категория: Other Welding Equipment >>>

- Поставщик: Wuxi,Longterm,Machinery,Technologies,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 23800.84 $* | 24990.14 $* |

| Aug-15-2025 | 23600.18 $* | 24780.57 $* |

| Jul-15-2025 | 19800.9 $* | 20790.13 $* |

| Jun-15-2025 | 23200.50 $* | 24360.9 $* |

| May-15-2025 | 20200.45 $* | 21210.77 $* |

| Apr-15-2025 | 22800.8 $* | 23940.82 $* |

| Mar-15-2025 | 22600.97 $* | 23730.12 $* |

| Feb-15-2025 | 22400.40 $* | 23520.45 $* |

| Jan-15-2025 | 22200.16 $* | 23310.71 $* |

Характеристики

all-sided technical team to research and improve the technology all the time. With good reputation and qualified machines, we have

supplied several high standard LPG cylinder production lines to the world markets, such as Nigeria,Kenya Ghana ,India, Turkey, Bangladesh, Vietnam, Thailand etc.

1. Company Brief Introduction

Our company specializes in LPG cylinder machinery with 30 years' background, supplying the better machine to help our customers

gain more profits is the motivation to let us move forward all the time, the experienced technicians and the well-trained sales

are the guarantee for each project, whatever the turnkey project or the existing plant upgrade project, we provide the pro-support

of each aspect to serve our customers well all the time.

Thus far, our machine is sold to US, Brazil, Turkey, Argentina, Thailand, Vietnam, Kenya, Tunisia, Nigeria, Bangladesh,

Philippines, Uganda, Sudan, Lebanon, Ecuador, among of them are the well-known LPG cylinder manufacturers in the world, such as

M*** tank from US (Indian branch factory), T** from Vietnam, A*** from Turkey, M** from Tunisia, Cy*** from Kenya, Fer** from

Philippines, B** from Bangladesh. Our machine helps them achieve an obvious improvement on saving the manpower and increasing the

productivity.

For production line, we have manual type, semi-auto type, fully automatic type.

Following is the brief introduction of the Key Process of the production line.

*All the machine can be customized, also the specification.

2. PROCESS STEPS

LPG Cylinder Production is composed of several sheet metal forming, surface treatment and testing processes. The process starts

with blanking, deep drawing and piercing, trimming and joggling. Next are the welding operations for valve boss, valve guard ring,

foot ring and the two halves. The finished cylinder is then heat treated, tested, shot blasted, painted and then the valve is

attached and final tested.

The main process steps are summarized below

2.1 LPG Cylinder Body Forming Line

2.2 LPG Cylinder Trimming & Beading

2.3 LPG Cylinder Guard Ring Production Line

2.4 LPG Cylinder Bottom Ring Production Line

2.5 LPG Cylinder Welding Line

2.6 LPG Cylinder Quality Controls

2.7 LPG Cylinder Heat Treatment Furnace

2.8 LPG Cylinder Shot Blasting

2.9 LPG Cylinder Metallization Line

2.10 LPG Cylinder Painting Line

2.11 LPG Cylinder Testing Line

We keep improving our machine technology all the time, our machines helped a lof of gas cylinder factories improve their production and gas cylinder quality with bigger capacity and much lower costing. For your better understanding, I am listing as follows:

1. Cylinder body auto making line, from decoiler to deep drawing, jogging and circle welding.

A: Fully automatic + Robots Auto feeding

B: 1000pcs/ 2000pcs Capacity as your needs

C:Only need max 3-5 people (only for change welding wires/ nozzels)

D:Video/ laser tracking +Patent Panasonic Welder

E: Workshop Land Saving, Cutting/ jogging/polishing in one machine

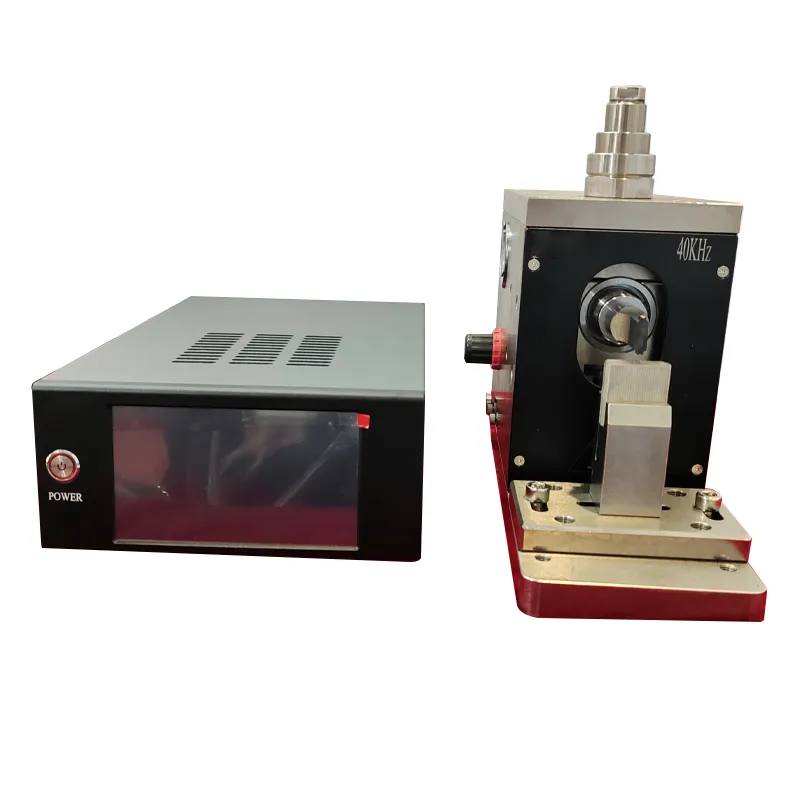

Welding is the most critical part of the production line, which engages the best cylinder performance and assures the good quality. Our welding machinery is the best cylinder & pressure vessel welding equipment in China and also TOP Ranked worldwide.

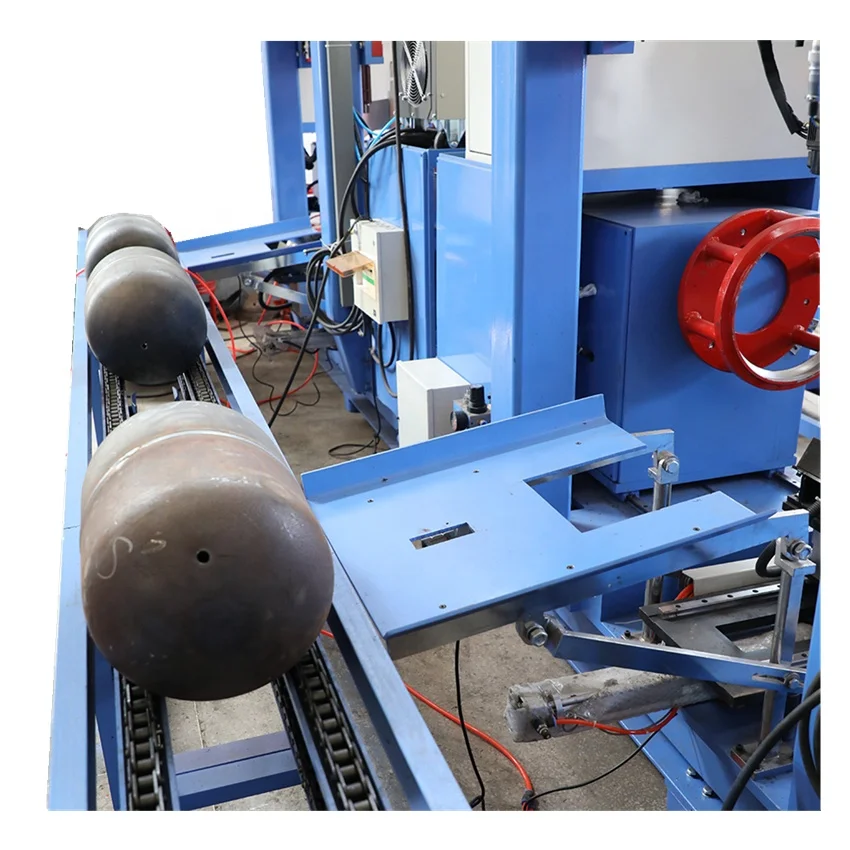

Full-auto welding machine includes socket welding, handle/collar welding, base ring welding, circumference welding, and all machines work automatically, the cylinder halves are conveyed by mechancial arm and chain, this system really saves much labor cost and improve the working efficiency apparently.

In order to relive all the stresses caused by forming and welding operations, the cylinders are passed through a heat treatment furnace where they are exposed to 930 º C degrees of temperature for certain time before getting cooled gradually.

After the tare weighing and marking of the cylinders, the valves are attached by automatic torque controlled screwing machines and tested against any leakage at the valve region by the pneumatic leakage testing machine of the finishing line.

One of the batch type quality control equipment called by the international standards is the burst expansion testing unit where the volumetric expansion ratio and the burst pressure is measured to the full satisfaction of even most stringent requirements.

Hole Punching Unit

Cylinder Halves Production

Auto Circumferential Welding

Thus far, our machine is sold to US, Brazil, Turkey, Argentina, Thailand, Vietnam, Kenya, Tunisia, Nigeria, Bangladesh,

Philippines, Uganda, Sudan, Lebanon, Ecuador, among of them are the well-known LPG cylinder manufacturers in the world, such as Manchester tank from US (Indian branch factory), TPA from Vietnam, Aygaz from Turkey, MBG from Tunisia, Cylinder works from Kenya,Ferrotechsteel from Philippines, BM Energy from Bangladesh. Our machine helps them achieve an obvious improvement on saving the manpower and increasing the productivity.

Certification & ReportAlthough it's one-pass welding, the welds quality can be guaranteed, we haven't got any complaint about the welds quality from our clients yet. In China, one cylinder will be selected from each batch randomly to do X-ray testing and the burst testing.I believe these tests will be done in your country as well.

producing PET plastic containers and bottles in all shapes.

Standard export package

Turnkey project LPG gas cylinder production line for new plant

Q: What size of LPG cylinder your machine can produce?

A: 6kg, 12kg,15kgs and 50kgs LPG cylinder for cooking and other size according customers’ requirement.

Q: Can you design machines according LPG cylinder technical drawing?

A: Sure, please send your technical drawing to us.

Q: What are the benefits to choose your machines?

A: Our machines are strong and reliable for long term industrial manufacturing

Enable us provide the most suitable proposal for you, please tell me following details:

1.Technical Drawing of the cylinders you want to make?

2.What size of cylinder you want to produce?(6kg, 12kg)

3.What diameter and thickness of the cylinder you want to make?

4.Are you new in this area or you already have some machines in the workshop?

5.Capacity you require, i.e. how many pieces and sizes you want to make per day?

Please don't hesitate to CONTACT US!