Южная Африка Бамбуковая глазурованная плитка алюминиевая Кровельная Панель роликовая

- Категория: Building Material Machinery >>>

- Поставщик: Cangzhou,Abena,Industry,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 12495.80 $* | 13120.26 $* |

| Aug-17-2025 | 12390.27 $* | 13010.70 $* |

| Jul-17-2025 | 10395.45 $* | 10915.67 $* |

| Jun-17-2025 | 12180.19 $* | 12789.29 $* |

| May-17-2025 | 10605.84 $* | 11135.10 $* |

| Apr-17-2025 | 11970.51 $* | 12569.13 $* |

| Mar-17-2025 | 11865.90 $* | 12458.16 $* |

| Feb-17-2025 | 11760.11 $* | 12348.97 $* |

| Jan-17-2025 | 11655.84 $* | 12238.61 $* |

Характеристики

Product Overview

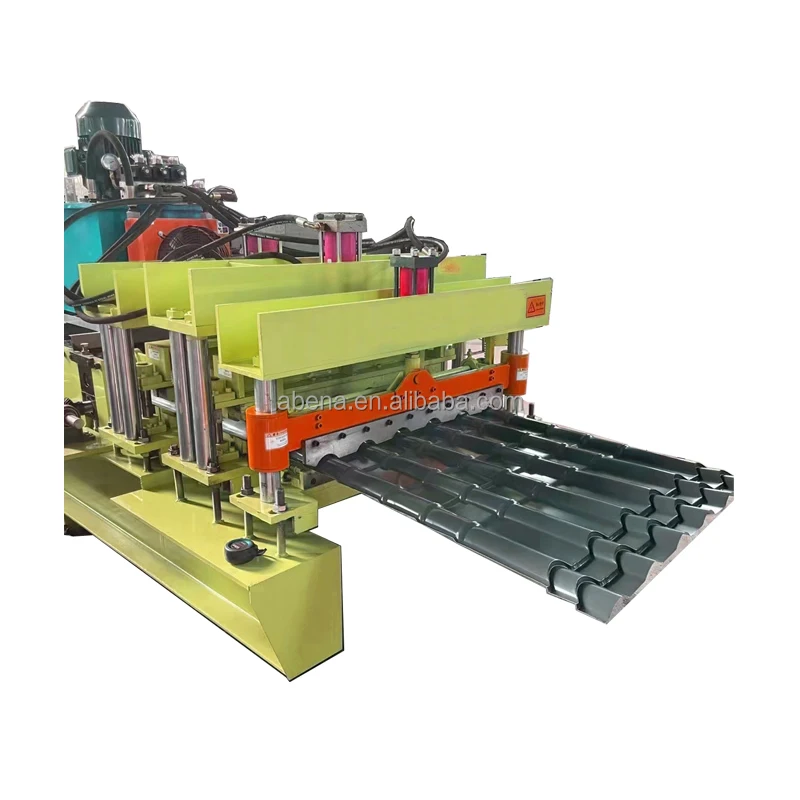

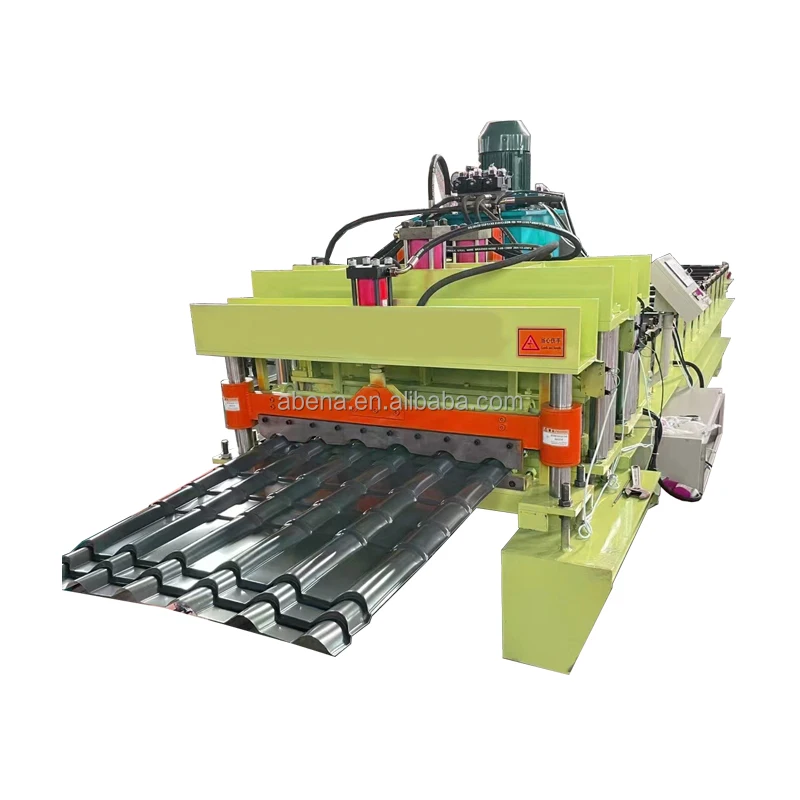

Metal glazed tile roofing panel roll forming machine

PRODUCT SPECIFICATIONS

No | TYPE | Data | SPECIFICATION | |||

1 | Raw material | material | PPGI GI | |||

2 | Bucket capacity | Feeding width | as drawing | |||

3 | Operating weight | thickness | 0.3-0.8mm | |||

2 | Decoiler | operate | manual | |||

5 | Max. breakout force | weight capacity | 5ton | |||

3 | Roll forming machine | roller station | 12 | |||

Diameter of shaft | 80mm | |||||

Roller material | 45# with 0.05mm chrome | |||||

Frame | steel sheet welding | |||||

Frame thickness | 18mm | |||||

Cutting Material | Cr 12 | |||||

Operation | automatic cutting | |||||

Working speed | 15-20m/minute | |||||

Power | Driving way | chain | ||||

Main motor | 5.5kw | |||||

Voltage | 380v 50hz | |||||

Electric box | PLC control system, inventer | |||||

PLC brand | delta | |||||

Inverter brand | delta | |||||

Language | chinese and english | |||||

Feature of the glazed tile roof machine

The components of the glazed tile roof roll forming machine include: decoiler, roll forming machine body, hydraulic cutting, plc control system, main motor, pump station, receving table.

Equipment features: glazed tile roof roll forming machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.

Equipment features: glazed tile roof roll forming machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.

Our company are professional product the roof roll forming machine manufacture , We manufacture and supply variants of cold roll forming machines in China, such as trapezoidal roofing sheet roll forming machine ,corrugated roofing roll forming machine ,glazed tile roll forming machine and double layer roofing sheet roll forming machine ,ridge cap roll forming machine and so on , our machine export all over the world like india.south africa.pakistan.Brazil .omen and so no , the color steel roof roll forming machine raw material thickness 0.3mm-0.8mm, we also can make other metal roofing sheet roll forming machine as your requirement ,meet your need ,our company aim :reputation first, customer first

Detail image

Decoiler

Loading capacity: 3tons

Hydraulic cutting

Controlled by oil pump

Automatic cutting as target products length Blade material: Cr12, quenching treatment

Automatic cutting as target products length Blade material: Cr12, quenching treatment

Roll forming body

Roller surfaces polish, hard plating dealing Polished surface and heat treatment towards molds can keep the molding plate surface smooth and not easy to be marked when it is being stamped

computer control system

Button press and screen touch operate Target piece`s length is adjustable Work automatically The system operate easily

Pump station

Hydraulic oil into the hydraulic oil tank, the pump drives the cutter work

Hydraulic oil: 46#

Oil add capacity: oil add 3/4 of box capacity Oil pressure: 8-10 MPa

Hydraulic oil: 46#

Oil add capacity: oil add 3/4 of box capacity Oil pressure: 8-10 MPa

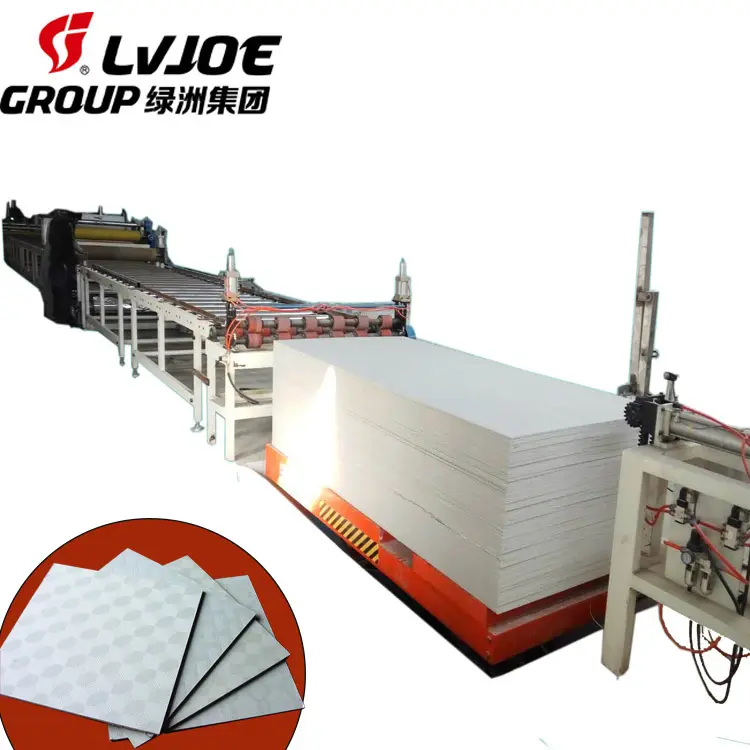

Recommend Products

Company Profile

Cangzhou abena industry co., ltd is specialized in the production of roll forming machinery.Our company was established in 2006,it is located in the cangzhou city of hebei Province , which is the center of the business and economy.

Main products: roof roll forming machine, floor deck roll forming machine, automatic decoiler, shutter door roll forming machine,light keel roll forming machine, purlin machine, leveling and slitting machine, and other related construction equipment. and soon. any requires please contact us

Main products: roof roll forming machine, floor deck roll forming machine, automatic decoiler, shutter door roll forming machine,light keel roll forming machine, purlin machine, leveling and slitting machine, and other related construction equipment. and soon. any requires please contact us

Packing and shipping

FAQ

A. Foreign commissioning

We will arrange our professional engineers to help you install and debug the machine well. Buyer should pay$100 for each engineer every day and responsible for transportation (including round-trip ticket), insurance, and suitable accommodation.

B.Warranty period

1.The warranty will be maintenance, maintain in the guarantee period of 18months starting from delivery. Because of the quality of equipment during guarantee period, we will provide the parts to charge freely, which is in the conditions of correct operation.

C. Training

During installation and adjustment of the equipment, our engineers are able to provide the training that buyer’s personnel request to operate and maintain the equipment.Including foundation construction, electrical works, hydraulic oil, safe operation and non-standard safety items, testing material and etc.

D. Services

Lifetime services to every customer.

Welcome to contact and visit us.Waiting for your cooperation sincerely.

We will arrange our professional engineers to help you install and debug the machine well. Buyer should pay$100 for each engineer every day and responsible for transportation (including round-trip ticket), insurance, and suitable accommodation.

B.Warranty period

1.The warranty will be maintenance, maintain in the guarantee period of 18months starting from delivery. Because of the quality of equipment during guarantee period, we will provide the parts to charge freely, which is in the conditions of correct operation.

C. Training

During installation and adjustment of the equipment, our engineers are able to provide the training that buyer’s personnel request to operate and maintain the equipment.Including foundation construction, electrical works, hydraulic oil, safe operation and non-standard safety items, testing material and etc.

D. Services

Lifetime services to every customer.

Welcome to contact and visit us.Waiting for your cooperation sincerely.