Точечная поставка нейлоновый провод PA6 пластиковый провод/износостойкий высокотемпературный Высокоэластичный/наполненный

- Категория: Other Plastic Products >>>

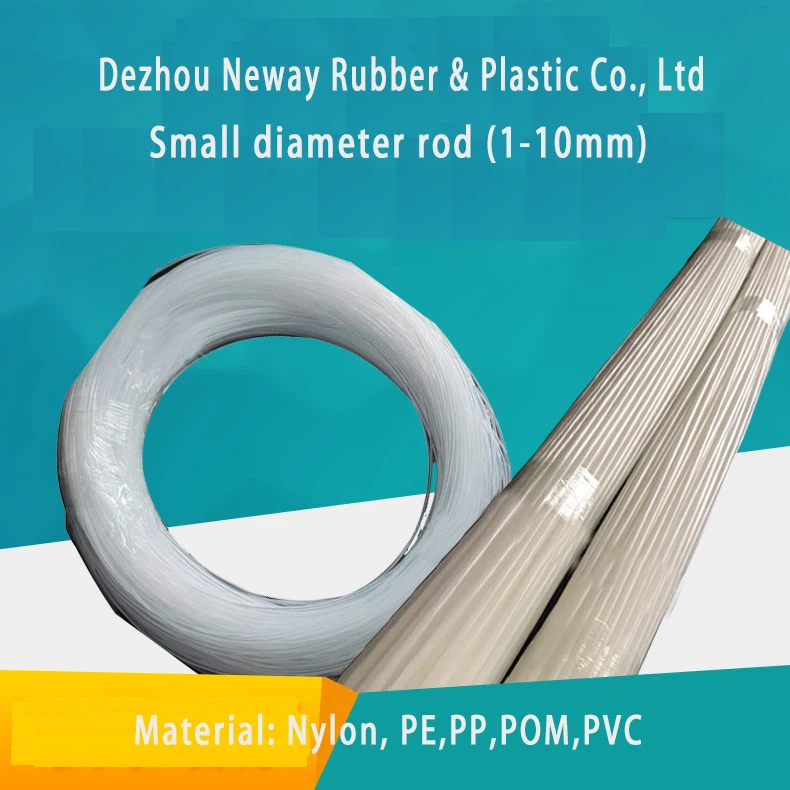

- Поставщик: Dezhou,Neway,Rubber,&,Plastic,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.19 $* | 0.81 $* |

| Aug-19-2025 | 0.49 $* | 0.37 $* |

| Jul-19-2025 | 0.5 $* | 0.94 $* |

| Jun-19-2025 | 0.30 $* | 0.69 $* |

| May-19-2025 | 0.97 $* | 0.21 $* |

| Apr-19-2025 | 0.9 $* | 0.69 $* |

| Mar-19-2025 | 0.85 $* | 0.98 $* |

| Feb-19-2025 | 0.65 $* | 0.70 $* |

| Jan-19-2025 | 0.31 $* | 0.67 $* |

Характеристики

Product Description

Product Features:

1, can be made of PP (polypropylene), PE (polyethylene), PA (nylon), POM (polyoxymethylene), ABS, PVC (polyvinyl chloride) PC (polycarbonate). Specifications of various materials: diameter from 2-200mm, length is not limited, can be customized, the length can be customized.

2, Product material: PP, PE, PA, POM, ABS, PVC, PC. Product advantages: all made of pure new materials, the product is non-toxic and tasteless, in line with food grade, smooth appearance and no impurities, roundness standard of product diameter, diameter tolerance of 0.1 wire, length can be customized.

3, the spot is white or the material is natural, the custom color is black blue green red yellow, etc.

Material Description: PP: Polypropylene is non-toxic, tasteless, food grade, low density, strength, stiffness, hardness and heat resistance are better than low-pressure polyethylene, can be used at around 100 °C. It has good dielectric properties and high-frequency insulation and is not affected by humidity, but becomes brittle at low temperature, not wear-resistant and easy to age. Common organic solvents such as acids and bases have little effect on it and can be used in food utensils.

PE: Polyethylene is tasteless, odorless, non-toxic, food grade, matte surface, milky white waxy particles, density of about

0.920g/cm3, melting point of 130 ° C ~ 145 ° C. Insoluble in water, slightly soluble in hydrocarbons, toluene, etc. It is

resistant to most acids and alkalis, has low water absorption, and maintains softness and electrical insulation at low

temperatures.

PA: Nylon is a ductile horny translucent or milky white crystalline resin. As a engineering plastic, the molecular weight of nylon is generally 1.5 to 30,000. Nylon has high mechanical strength, high softening point, heat resistance, low friction coefficient, abrasion resistance, self-lubricating property, shock absorption and sound absorbing property, oil resistance, weak acid resistance, alkali resistance and general solvent, and good electrical insulation. Self-extinguishing, non-toxic, odorless, weather resistant, and poor dyeability.

1, can be made of PP (polypropylene), PE (polyethylene), PA (nylon), POM (polyoxymethylene), ABS, PVC (polyvinyl chloride) PC (polycarbonate). Specifications of various materials: diameter from 2-200mm, length is not limited, can be customized, the length can be customized.

2, Product material: PP, PE, PA, POM, ABS, PVC, PC. Product advantages: all made of pure new materials, the product is non-toxic and tasteless, in line with food grade, smooth appearance and no impurities, roundness standard of product diameter, diameter tolerance of 0.1 wire, length can be customized.

3, the spot is white or the material is natural, the custom color is black blue green red yellow, etc.

Material Description: PP: Polypropylene is non-toxic, tasteless, food grade, low density, strength, stiffness, hardness and heat resistance are better than low-pressure polyethylene, can be used at around 100 °C. It has good dielectric properties and high-frequency insulation and is not affected by humidity, but becomes brittle at low temperature, not wear-resistant and easy to age. Common organic solvents such as acids and bases have little effect on it and can be used in food utensils.

PE: Polyethylene is tasteless, odorless, non-toxic, food grade, matte surface, milky white waxy particles, density of about

0.920g/cm3, melting point of 130 ° C ~ 145 ° C. Insoluble in water, slightly soluble in hydrocarbons, toluene, etc. It is

resistant to most acids and alkalis, has low water absorption, and maintains softness and electrical insulation at low

temperatures.

PA: Nylon is a ductile horny translucent or milky white crystalline resin. As a engineering plastic, the molecular weight of nylon is generally 1.5 to 30,000. Nylon has high mechanical strength, high softening point, heat resistance, low friction coefficient, abrasion resistance, self-lubricating property, shock absorption and sound absorbing property, oil resistance, weak acid resistance, alkali resistance and general solvent, and good electrical insulation. Self-extinguishing, non-toxic, odorless, weather resistant, and poor dyeability.

POM: POM rod (POM rod)

Polyoxymethylene plastic is a high-density, side-chain, high-crystallization linear polymer with excellent overall properties.

The surface is smooth, shiny and hard, dense yellowish or white, with high crystallinity, good coloration, size, and minimal water absorption. It has high hardness and rigidity, high creep resistance and stress relaxation ability, excellent wear resistance, self-lubricating property, and fatigue property, which cannot be compared with other engineering plastics. It has a high heat distortion temperature and can be used for a long time in the temperature range of -40 °C to 104 °C. Its dielectric loss and dielectric constant vary little over a wide range of frequencies and temperatures, maintaining good arc resistance. Good resistance to solvents, oils, weak acids, weak bases, etc.

ABS: ABS rod has excellent impact strength, good dimensional stability, dyeability, high mechanical strength, high stiffness, low water absorption, good corrosion resistance, simple connection, non-toxic and tasteless, and electrical insulation properties. It can resist heat and deformation, and has high impact toughness under low temperature conditions. It is also a hard, hard-to-scratch, non-deformable material. Low water absorption; high dimensional stability.

PVC : Polyvinyl chloride rod is a kind of non-crystalline material with good flame retardancy, good chemical stability and only low internal cracking force. It has excellent flame retardancy, wear resistance, chemical resistance, comprehensive mechanical properties. PVC has become one of the most widely used plastics in the fields of industry, construction, agriculture, daily life, packaging, electric power, public utilities, etc. Applications, together with polyethylene (PE), polypropylene (PP), polystyrene (PS) and ABS are collectively referred to as the five general-purpose resins.

PC: Polycarbonate (PC) rods have good mechanical properties, impact resistance and weather resistance. Maintain stable physical properties in the range of -40 ° C to +120 ° C. The size is stable when heated. Light weight, excellent electrical and dielectric properties, good light transmission, high transparency, transparency, low haze, and light transmittance of 93%..

PE: medical appliance parts, seals, cutting boards, sliding profiles. Widely used in chemical, machinery, chemical, electric

power, clothing, packaging, food and other industries. Widely used in oilfield, chemical and postal and telecommunications.

PA: Widely used in chemical machinery and anti-corrosion equipment. Wear parts, transmission structural parts, household appliance parts, automobile manufacturing parts, screw rods to prevent mechanical parts, chemical machinery parts, chemical equipment, etc. Used as support strips for nylon strips, nylon pins, and garment edging strips.

ABS: ABS sticks in food industry parts, building models, hand-made, phase-forming electronic industrial parts, refrigerator

refrigeration industry, electronic and electrical fields, pharmaceutical industry, auto parts (dashboard, tool hatch, wheel cover, mirror box, etc.) , radio casings, telephone handles, high-strength tools (vacuum cleaners, hair dryers, blenders, lawn mowers, etc.), typewriter keyboards, recreational vehicles such as golf carts and jet skis.

PVC: Strong corrosion resistance: most suitable for corrosion resistant equipment. Easy processing, cutting, welding and bending are extremely easy. High strength, high rigidity and high hardness; good electrical insulation; good chemical stability; self-extinguishing; low water absorption; easy to bond, easy to paint, low in price

Polyoxymethylene plastic is a high-density, side-chain, high-crystallization linear polymer with excellent overall properties.

The surface is smooth, shiny and hard, dense yellowish or white, with high crystallinity, good coloration, size, and minimal water absorption. It has high hardness and rigidity, high creep resistance and stress relaxation ability, excellent wear resistance, self-lubricating property, and fatigue property, which cannot be compared with other engineering plastics. It has a high heat distortion temperature and can be used for a long time in the temperature range of -40 °C to 104 °C. Its dielectric loss and dielectric constant vary little over a wide range of frequencies and temperatures, maintaining good arc resistance. Good resistance to solvents, oils, weak acids, weak bases, etc.

ABS: ABS rod has excellent impact strength, good dimensional stability, dyeability, high mechanical strength, high stiffness, low water absorption, good corrosion resistance, simple connection, non-toxic and tasteless, and electrical insulation properties. It can resist heat and deformation, and has high impact toughness under low temperature conditions. It is also a hard, hard-to-scratch, non-deformable material. Low water absorption; high dimensional stability.

PVC : Polyvinyl chloride rod is a kind of non-crystalline material with good flame retardancy, good chemical stability and only low internal cracking force. It has excellent flame retardancy, wear resistance, chemical resistance, comprehensive mechanical properties. PVC has become one of the most widely used plastics in the fields of industry, construction, agriculture, daily life, packaging, electric power, public utilities, etc. Applications, together with polyethylene (PE), polypropylene (PP), polystyrene (PS) and ABS are collectively referred to as the five general-purpose resins.

PC: Polycarbonate (PC) rods have good mechanical properties, impact resistance and weather resistance. Maintain stable physical properties in the range of -40 ° C to +120 ° C. The size is stable when heated. Light weight, excellent electrical and dielectric properties, good light transmission, high transparency, transparency, low haze, and light transmittance of 93%..

PE: medical appliance parts, seals, cutting boards, sliding profiles. Widely used in chemical, machinery, chemical, electric

power, clothing, packaging, food and other industries. Widely used in oilfield, chemical and postal and telecommunications.

PA: Widely used in chemical machinery and anti-corrosion equipment. Wear parts, transmission structural parts, household appliance parts, automobile manufacturing parts, screw rods to prevent mechanical parts, chemical machinery parts, chemical equipment, etc. Used as support strips for nylon strips, nylon pins, and garment edging strips.

ABS: ABS sticks in food industry parts, building models, hand-made, phase-forming electronic industrial parts, refrigerator

refrigeration industry, electronic and electrical fields, pharmaceutical industry, auto parts (dashboard, tool hatch, wheel cover, mirror box, etc.) , radio casings, telephone handles, high-strength tools (vacuum cleaners, hair dryers, blenders, lawn mowers, etc.), typewriter keyboards, recreational vehicles such as golf carts and jet skis.

PVC: Strong corrosion resistance: most suitable for corrosion resistant equipment. Easy processing, cutting, welding and bending are extremely easy. High strength, high rigidity and high hardness; good electrical insulation; good chemical stability; self-extinguishing; low water absorption; easy to bond, easy to paint, low in price

Product Name | Small plastic rod small nylon rod thin plastic rod |

Specifications (size) | 2mm-200mm Support customized |

Material | PA,PP,PE,PVC,PETG,PC,PET,PBT,TPE,TPU,ABS,etc.Support customized |

Color | Support customized |

Size | Support customized |

Length | Support customized |

Application | Medical, packaging, Food, Tool,machinery, Toys, crafts,etc. |

OEM | Accept |

Packing & Delivery

Packing Details : Inner plastic bag,outside carton box,last is the pallet,all are based on the customers' requirments

Delivery Details : 10-30 days after you confirm the samples

Payment terms: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us.

Delivery Details : 10-30 days after you confirm the samples

Payment terms: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us.

Company Profile

Dezhou Neway Rubber & Plastic Co., Ltd. is located in Dezhou City, Shandong Province. It is a modern high-tech enterprise integrating R&D, manufacturing and market development of engineering plastics and rubber and plastic products. The products produced by our company have covered more than 20 provinces and autonomous regions across the country and exported to more than 30 countries such as Europe, America, Africa, Russia, Mongolia, Uzbekistan and so on. Our products are widely used in food machinery, beer and beverage machinery, steel rolling, mining machinery, textile machinery, automobiles, automated conveying machinery, electric power, ports, ship terminals, coking, coal, papermaking, textiles, chemicals, environmental protection and other related industries, The main production materials are UHMW-PE, HDPE, MC Nylon, PA6, PA66, POM, PVC, ABS, polyurethane, silicone, rubber and other sheets of customized processing.

We company owns more than 100 lathes, grinders, planers, milling machines, punching machines, CNC gantry CNC machining centers, injection molding machine equipment, vulcanizer equipment, and extruder equipment.

Adhering to the principle of quality first, customer first, the company continues to increase investment in product quality and new product development, and makes unremitting efforts to provide customers with more perfect products and services. "Practical innovation, honesty and eternal" is our business philosophy , Is willing to cooperate with new and old customers for a long time and seek a win-win situation.

We company owns more than 100 lathes, grinders, planers, milling machines, punching machines, CNC gantry CNC machining centers, injection molding machine equipment, vulcanizer equipment, and extruder equipment.

Adhering to the principle of quality first, customer first, the company continues to increase investment in product quality and new product development, and makes unremitting efforts to provide customers with more perfect products and services. "Practical innovation, honesty and eternal" is our business philosophy , Is willing to cooperate with new and old customers for a long time and seek a win-win situation.

High quality

Our products have passed the ISO9001:2008 quality system certification,you can rest assured to buy.

Best raw material

We have cooperated with several large raw material companies,our company have advance technology and professional worker and sales team,and add good raw material,I think our products quality is very good,and you can rest assured to buy.

Smile and good services

Our company very pay attention to development and worker's good attitude,if you talk with me,you are talking with a friend of you will feel.

Our products have passed the ISO9001:2008 quality system certification,you can rest assured to buy.

Best raw material

We have cooperated with several large raw material companies,our company have advance technology and professional worker and sales team,and add good raw material,I think our products quality is very good,and you can rest assured to buy.

Smile and good services

Our company very pay attention to development and worker's good attitude,if you talk with me,you are talking with a friend of you will feel.

FAQ

1. Q: Are you trading company or manufacturer ?

A: We are manufacturer.

2. Q: How long is your delivery time?

A: According to the difficulty and quantity of product processing,a reasonable arrival time will be given to you. Usually 2-5

daysfor CNC machine processing parts. It will take around 2-4 weeks for mold making.

3. Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

4. Q: Can you do assembly and customized package for us?

A: We have an assembly factory and can assemble all kinds of plastic, metal and electronic parts for you. For the finished

products,we can customized the retail package and you can sell it directly after receiving them.

A: We are manufacturer.

2. Q: How long is your delivery time?

A: According to the difficulty and quantity of product processing,a reasonable arrival time will be given to you. Usually 2-5

daysfor CNC machine processing parts. It will take around 2-4 weeks for mold making.

3. Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

4. Q: Can you do assembly and customized package for us?

A: We have an assembly factory and can assemble all kinds of plastic, metal and electronic parts for you. For the finished

products,we can customized the retail package and you can sell it directly after receiving them.