Малогабаритная машина для переработки свинцово-кислотных

- Категория: Waste Treatment Machinery >>>

- Поставщик: Zhengzhou,Tianyu,Heavy,Industry,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.27 $* | 0.30 $* |

| Aug-17-2025 | 0.83 $* | 0.21 $* |

| Jul-17-2025 | 0.44 $* | 0.28 $* |

| Jun-17-2025 | 0.85 $* | 0.61 $* |

| May-17-2025 | 0.99 $* | 0.74 $* |

| Apr-17-2025 | 0.80 $* | 0.34 $* |

| Mar-17-2025 | 0.97 $* | 0.34 $* |

| Feb-17-2025 | 0.87 $* | 0.37 $* |

| Jan-17-2025 | 0.31 $* | 0.99 $* |

Характеристики

Recycling Background

The global battery recycling market size was valued at $11.1 billion in 2020, and is expected to reach $66.6 billion by 2030, registering a CAGR of 19.5% from 2021 to 2030.

Battery recycling helps to prevent the degrading of the environment and health hazards that disposable batteries pose especially after they are dumped in the landfills. Batteries consist of various harmful and toxic metals such as mercury, nickel, lead, cadmium, and others. These substances, if exposed to the soil can contaminate both the soil and the underground water resources, in the case of landfills. During the process of incineration, lead acid batteries release such toxic metals to the environment along with the ash. Therefore, the rise in environmental issues and the health hazards following environment degradation are the major factors boosting the global lead acid battery recycling market.

Product Overview

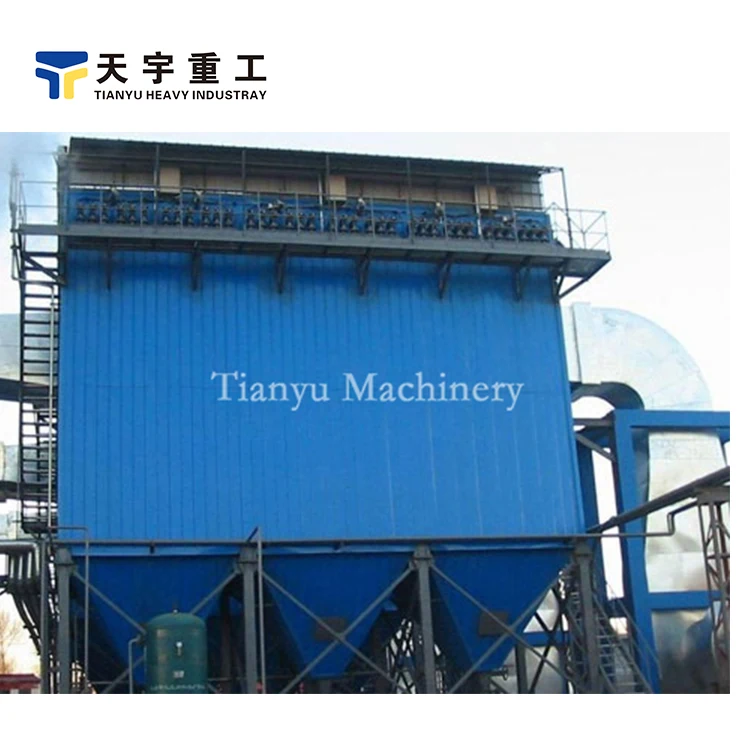

ZHENGZHOU TIANYU HEAVY INDUSTRY MACHINERY CO., LTD., thanks to their considerable

experience gained in many years of activity in the waste recycling are in a position to offer custom made plants to recover valuable materials as lead, plastics and acid from scrap lead-acid batteries, meeting the most stringent environmental laws.

A highly experienced technical team together with a consistent technological updating enable us to design custom-made equipment, machinery and plants and offer reliable solutions to satisfy the specific requirements of individual clients.

experience gained in many years of activity in the waste recycling are in a position to offer custom made plants to recover valuable materials as lead, plastics and acid from scrap lead-acid batteries, meeting the most stringent environmental laws.

A highly experienced technical team together with a consistent technological updating enable us to design custom-made equipment, machinery and plants and offer reliable solutions to satisfy the specific requirements of individual clients.

We may offer both turn-key complete recycling lines of any size and single equipment including battery breaker, desulphurization and crystallization, rotary furnaces, refining kettle, lead pumps and agitators, ingot casting line, sanitary air and water treatment systems, plastic upgrading line etc. Machines and equipment can be installed in existing recycling plants to improve their performances.

Technical Process

This device can be personalized design according to customer’s demand, equipped with auto

control program; the technical data of the device is displayed on the control screen, and the screen also with production monitor function. The whole devices can be operated safely by 1 person by control the computer. All the production processes only need 3~5 persons to handle.

Lead grid, lead paste cake, heavy plastic, light plastic after breaking and separating will be stored individually. The whole device achieves zero discharge, eco-friendly environment.

This device obtained many invention patents and utility model patents.

Device composition: vibrating feeder, belt conveyor, battery breaking machine, hydraulic separation machine, and partition

conveyor.

Total lead recovery rate≥98%,

Plastic recovery rate≥98%,

Water content in lead paste <13%

control program; the technical data of the device is displayed on the control screen, and the screen also with production monitor function. The whole devices can be operated safely by 1 person by control the computer. All the production processes only need 3~5 persons to handle.

Lead grid, lead paste cake, heavy plastic, light plastic after breaking and separating will be stored individually. The whole device achieves zero discharge, eco-friendly environment.

This device obtained many invention patents and utility model patents.

Device composition: vibrating feeder, belt conveyor, battery breaking machine, hydraulic separation machine, and partition

conveyor.

Total lead recovery rate≥98%,

Plastic recovery rate≥98%,

Water content in lead paste <13%

Final Product

Company Profile

FAQ

1.What is the recovery rate of Lead Recycling plant?

The Recovery rate of Lead recycling Plant is defined in two ways. Recovery from the complete weight of Battery Scrap (including plastic, acid) is about 55-62% depending upon the size & grade of Batteries available at the location.

However the recovery/efficiency in terms of Lead metal content which is feed inside the Furnace is about 99%. The above

percentages will vary slightly in case of Blast Furnace in comparison to Rotary Type of Furnace.

The Recovery rate of Lead recycling Plant is defined in two ways. Recovery from the complete weight of Battery Scrap (including plastic, acid) is about 55-62% depending upon the size & grade of Batteries available at the location.

However the recovery/efficiency in terms of Lead metal content which is feed inside the Furnace is about 99%. The above

percentages will vary slightly in case of Blast Furnace in comparison to Rotary Type of Furnace.

2. Can Maintenance Free Battery &Car Battery be operated in the same system?

Yes in our system the Maintenance Free Battery &Car Battery can be processed but in separate batches only.

3. What is the electricity requirement for the standard plant?

Electricity requirement depends upon size of plant. For Example a typical plant of about 300MT Lead production per month consumes apporx 120kwhr/MT.

Yes in our system the Maintenance Free Battery &Car Battery can be processed but in separate batches only.

3. What is the electricity requirement for the standard plant?

Electricity requirement depends upon size of plant. For Example a typical plant of about 300MT Lead production per month consumes apporx 120kwhr/MT.

4. What are the standard sizes of Lead Recycling Plant you offer?

The standard sizes of Lead Recycling/Smelting Plant are:

• About annual 50,000 tons Lead production Plant

• About annual 100,000 tons Lead production plant

• About annual 150,000 tons Lead production plant.

* About annual 200,000 tons Lead production plant & so on based on the customer requirement.

We also provide Tailor made comprehensive turnkey projects for Lead Recycling/Smelting Plant.

The standard sizes of Lead Recycling/Smelting Plant are:

• About annual 50,000 tons Lead production Plant

• About annual 100,000 tons Lead production plant

• About annual 150,000 tons Lead production plant.

* About annual 200,000 tons Lead production plant & so on based on the customer requirement.

We also provide Tailor made comprehensive turnkey projects for Lead Recycling/Smelting Plant.